Evaluation method of interface between lithium ion battery anodes and electrolytes

A lithium-ion battery and evaluation method technology, which is applied in the field of evaluation of the interface between the negative electrode and the electrolyte of the lithium-ion battery, can solve the problems of less detection methods for the negative electrode active material and the electrolyte, and fewer evaluation methods for the stability of the SEI film, and achieve shortening The effect of screening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

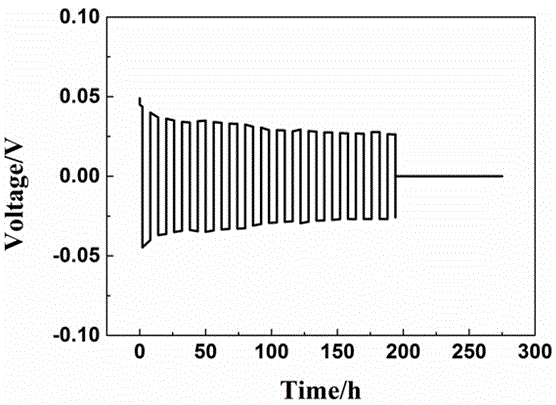

[0024] On the lithium-ion battery production line, select a batch of negative electrode sheets coated on one side, and use electrolyte A to assemble them into a CR2016 button-type symmetrical battery; after standing for a period of time, apply a density of 0.25 mA to the symmetrical battery. cm -2 The constant current is used, the test temperature is 25°C, the deposition and dissolution time is 6h, and the cycle performance test is carried out to analyze the change trend of the polarization voltage.

[0025] Note: A symmetrical battery refers to a battery with two pole pieces that are exactly the same; deposition and dissolution time refers to the time it takes to go through one charge-discharge cycle.

[0026] Such as figure 1 As shown, with the prolongation of the test time, the polarization voltage of the symmetrical battery tends to be stable, and the stable value is 30mV. As metal lithium continues to deposit and dissolve, lithium dendrites will form during this process...

Embodiment 2

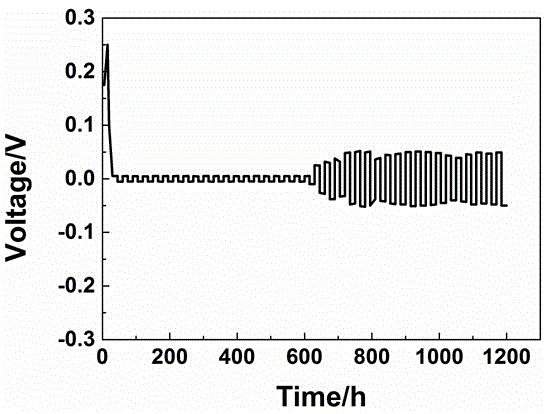

[0028] Select the same batch of negative electrode sheets coated on one side, and use electrolyte B to assemble them into a CR2016 button-type symmetrical battery; after standing for a period of time, apply a density of 0.25mA cm to the symmetrical battery -2 The constant current, the test temperature is 25°C, the deposition and dissolution time is 15h, the cycle performance test is carried out, and the change trend of the polarization voltage is analyzed.

[0029] Such as figure 2 As shown, the polarization voltage of the symmetrical cell was stable at 5mV during the cycle test time of 600h. Under more severe conditions, the symmetric battery still has no short circuit phenomenon in the continuous polarization process of more than 1200h, but the polarization voltage increases from 5mV to about 50mV. and figure 1 It can be seen from the comparison that the interface stability between the negative electrode sheet and the electrolyte B is better, and the compatibility is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com