Order-driven discrete manufacturing process energy consumption optimization method

A manufacturing process and optimization method technology, applied in the direction of digital control, program control, adaptive control, etc., can solve the problems of inability to guarantee the optimal coordination of multiple objectives, less research on discrete manufacturing processes, and lack of practicability in low-energy production planning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

[0092] The order-driven discrete manufacturing process energy consumption optimization method provided by the present invention includes the following steps:

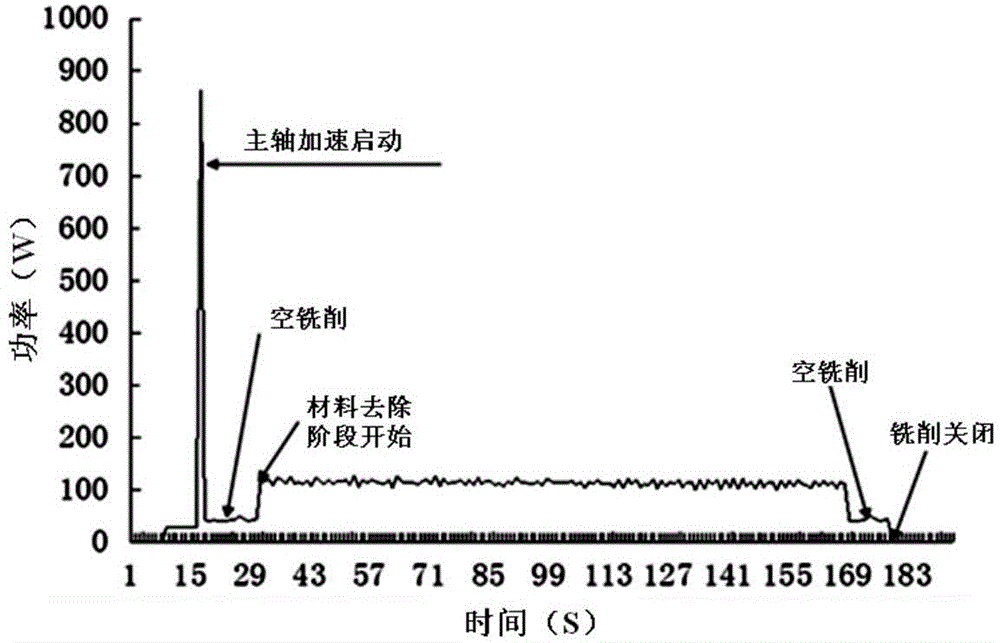

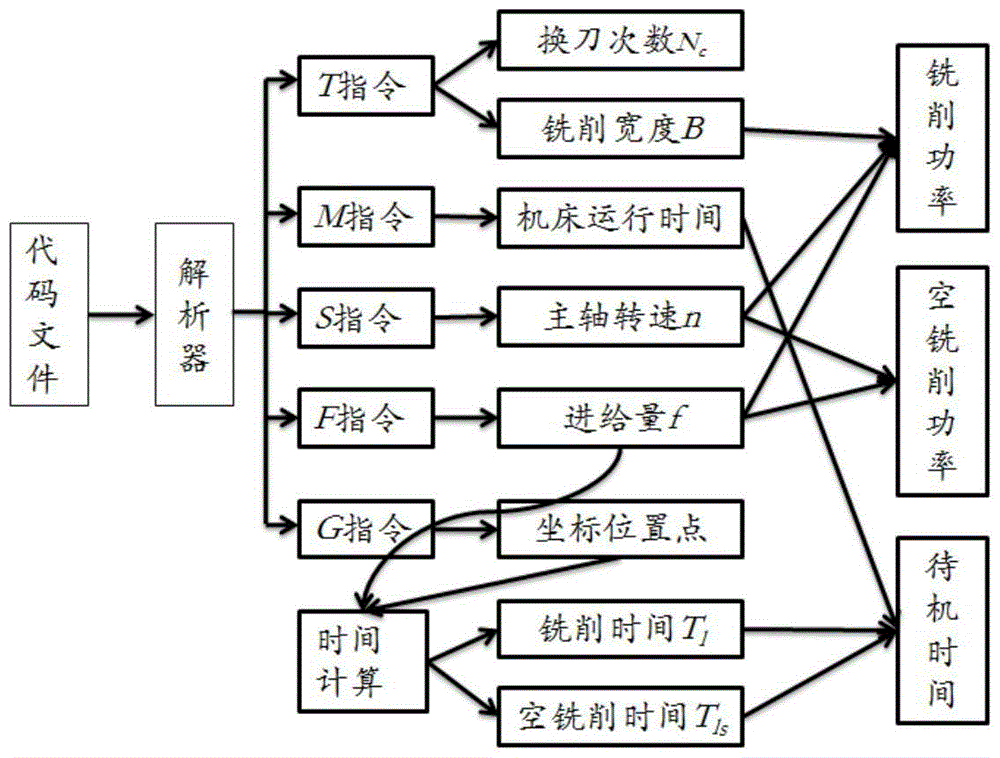

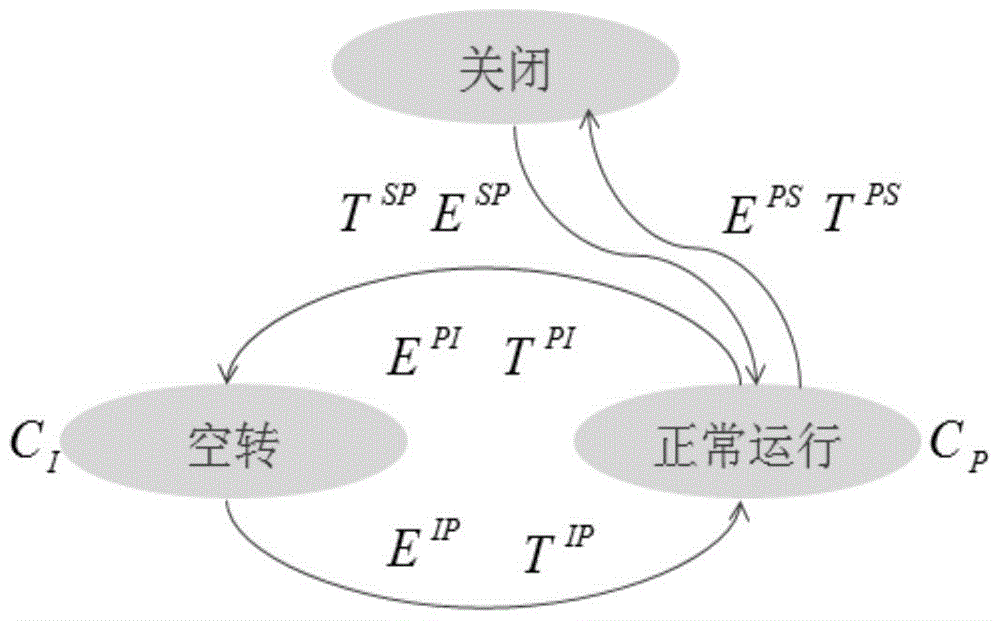

[0093] 1) According to the NC code of a certain process of the part to be processed, the load time, no-load time, tool change times, total standby time, total start-up time, feed rate under load, spindle speed, tool model, etc. ;

[0094] 2) Substituting the load power and no-load power calculation model into the load power and no-load power calculation model to obtain the load power and no-load power according to the feed rate, spindle speed, tool model, etc. obtained in step 1);

[0095] 3) According to the variables obtained in step 1) and step 2) and the inherent start-up power, standby power and tool change energy consumption of the selected machine tool for this process, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com