Lead wire framework used for packaging structure without pin and manufacturing method thereof, and packaging structure

A leadless packaging and lead frame technology, used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of frame yield loss, poor plating, frame deformation, etc., and improve the wiring layout. , shorten the length of the line, the effect of reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

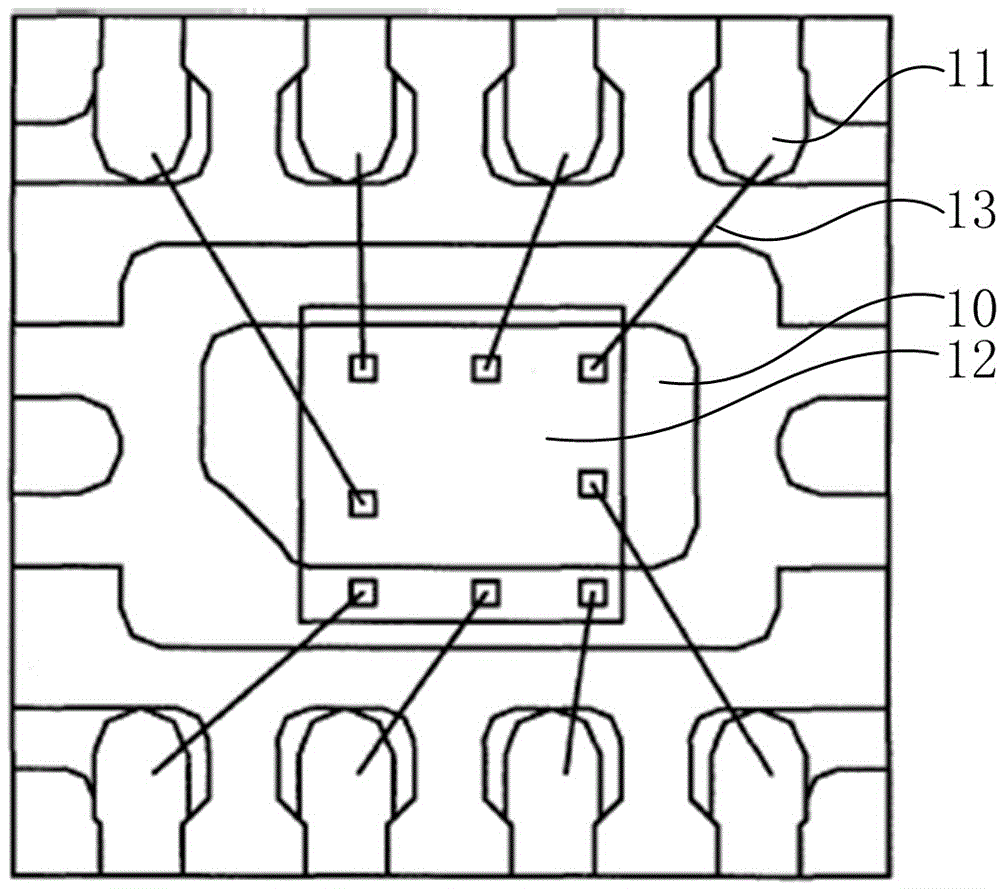

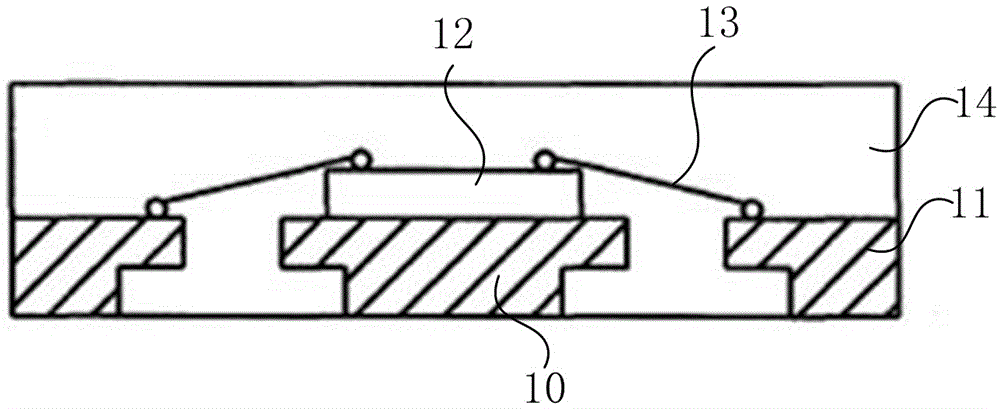

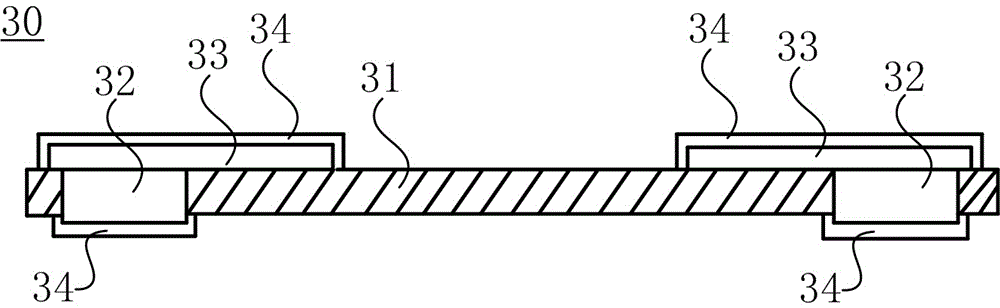

[0022] The specific implementations of the lead frame for the leadless packaging structure, the manufacturing method and the packaging structure provided by the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only used to illustrate the structure of the lead frame of the present invention, and are not used to limit the dimensional relationship among the various components of the present invention.

[0023] see image 3 , the lead frame 30 used in the leadless packaging structure of the present invention includes a frame body 31 and a plurality of conductive posts 32 penetrating through the frame body 31 .

[0024] The lead frame body 31 is made of an insulating material, and the insulating material may be an insulating material known in the prior art, which is not limited in the present invention. In this specific embodiment, the frame body 31 is relatively thin and is a film frame body.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com