Milling cutter type cable stripper

A stripper and milling cutter technology, which is applied in the directions of circuit/collector parts, cable installation, cable installation device, etc. Simple, low physical exertion for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

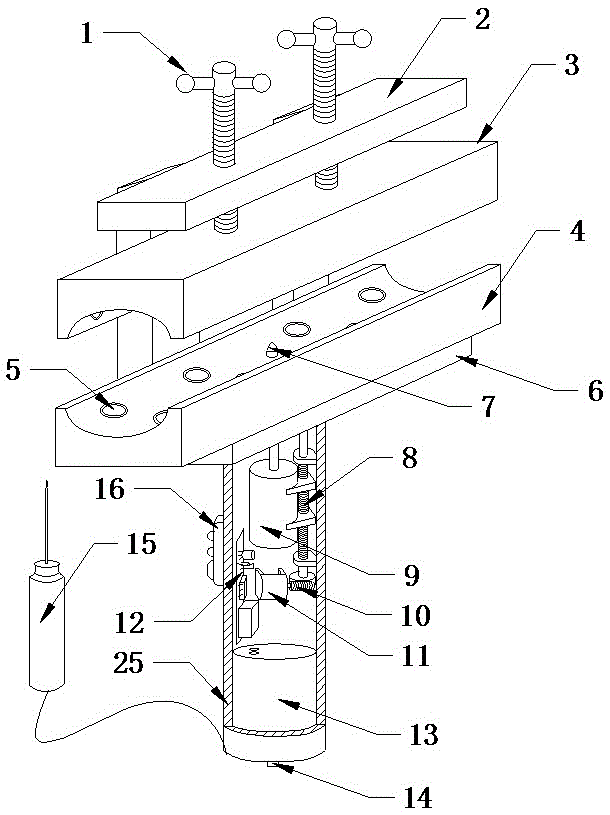

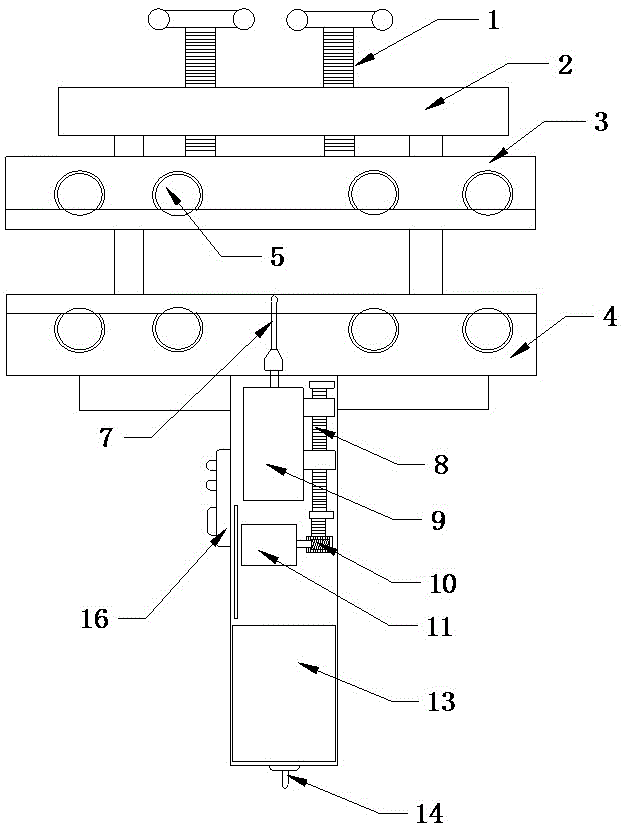

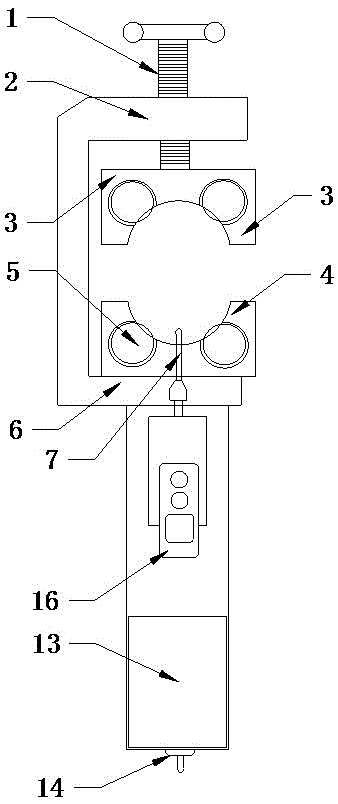

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] Such as Figure 1-Figure 3 As shown, the milling cutter type cable stripper of this embodiment is composed of six major parts: the cable holding device, the milling cutter 7 and the milling cutter motor 9, the milling cutter stroke control device, the control circuit, the power battery 13 and the casing 25 .

[0029] This embodiment specifically includes a compression bolt 1, an upper fixing frame 2, an upper compression plate 3, a lower compression plate 4, a spherical bulls-eye bearing 5, a lower fixing frame 6, a milling cutter 7, a milling cutter motor guide rail 8, a milling cutter Motor 9, worm gear reducer 10, rail motor 11, control circuit board 12, power battery 13, main power switch 14, auxiliary electrode pin 15, function switch 16, milling cutter motor switch 17, rail switch 18, central logic control circuit 19. Milling cutter motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com