Orthosis manufacturing method with macroscopic-microcosmic integration feature

A manufacturing method and technology of orthotics, applied in medical science and other fields, can solve problems such as uneven quality of orthotics, inability to guarantee corrective effect, harsh working environment, etc., and achieve saving of production materials, promotion of rehabilitation orthopedic effects, and beautiful appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

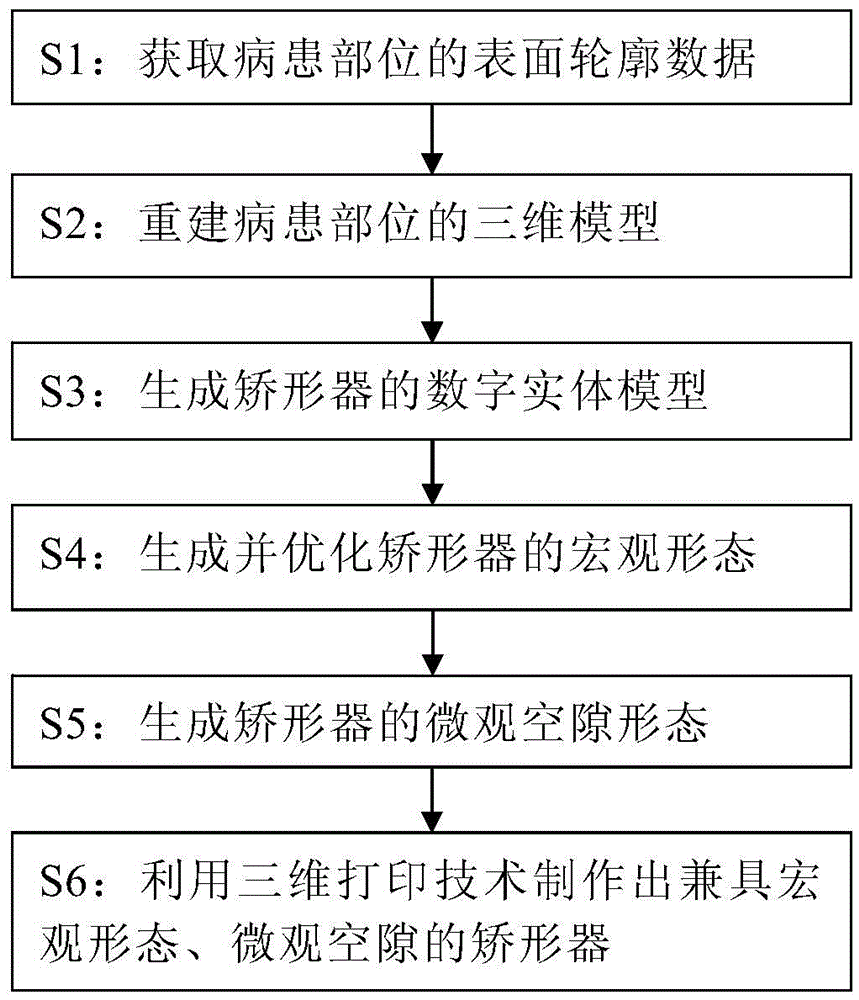

[0030] figure 1 It is a schematic flow chart of the method of the present invention. As shown in the figure, the manufacturing method of the orthosis disclosed by the present invention has the characteristics of macro-micro integration, including the following steps:

[0031] S1: Perform three-dimensional scanning of the patient's part to obtain the surface contour data of the patient's part;

[0032] A three-dimensional scanning device (for example, a hand-held three-dimensional scanner) is used to scan the patient's part to obtain surface contour data of the patient's part. During the scanning process, the surface contour data of the patient's part is displayed on the monitor in real time in the form of point cloud data or surface data (surface data automatically connected by point data), and the scanner can analyze the surface contour acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com