Production method for truck bolster springs

A production method and bogie technology, applied in the direction of low internal friction springs, springs/shock absorbers, mechanical equipment, etc., can solve the problems of impact resistance, poor durability, affecting the normal use of trucks, and short service life. The effect of excellent impact resistance and durability, long service life and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

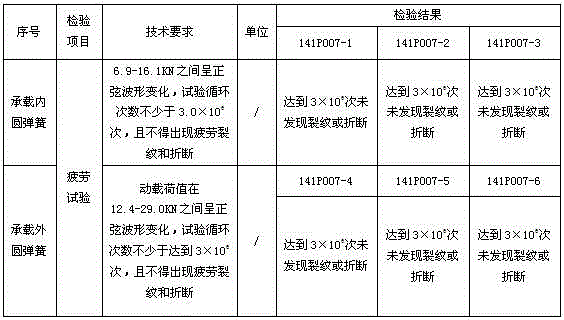

[0011] Taking the production of K2 bogie bolster springs as an example, the following steps are included:

[0012] (1) Rolling: The temperature during hot rolling is controlled at 850°C, and the pitch of the spring is adjusted according to production requirements after rolling;

[0013] (2) Stress relief annealing: control the stress relief annealing so that the temperature of the shackle after processing is 820°C; this can eliminate the internal stress formed during rolling, stabilize the spring size, and increase the tensile strength and elastic limit of the wire;

[0014] (3) Standing or strong pressure treatment: Grind the two ends of the spring after stress relief annealing, cut the tail, and then perform standing or strong pressure treatment; it can increase the bearing capacity of the static load of the spring by 25%;

[0015] (4) Surface anti-corrosion treatment: galvanize the surface of the formed spring, paint it with oil or paint, inspect and pack it. This step imp...

Embodiment 2

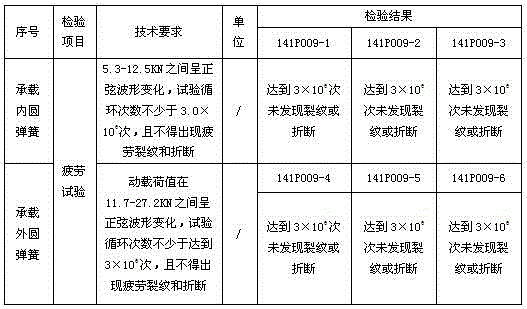

[0021] Taking the production of K5 bogie bolster springs as an example, the following steps are included:

[0022] (1) Rolling: The temperature during hot rolling is controlled at 920°C, and the pitch of the spring is adjusted according to production requirements after rolling;

[0023] (2) Stress relief annealing: control the stress relief annealing so that the temperature of the shackle after processing is 900°C; this can eliminate the internal stress formed during rolling, stabilize the spring size, and increase the tensile strength and elastic limit of the wire;

[0024] (3) Standing or strong pressure treatment: Grind the two ends of the spring after stress relief annealing, cut the tail, and then perform standing or strong pressure treatment; it can increase the bearing capacity of the static load of the spring by 25%;

[0025] (4) Surface anti-corrosion treatment: galvanize the surface of the formed spring, paint it with oil or paint, inspect and pack it. This step imp...

Embodiment 3

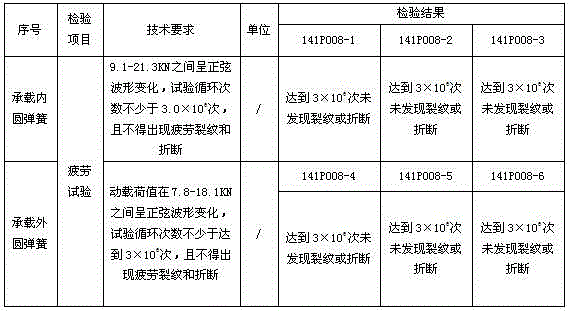

[0031] Taking the production of K6 bogie bolster springs as an example, the following steps are included:

[0032] (1) Rolling: The temperature during hot rolling is controlled at 890°C, and the pitch of the spring is adjusted according to production requirements after rolling;

[0033] (2) Stress relief annealing: control the stress relief annealing so that the temperature of the shackle after processing is 870°C; this can eliminate the internal stress formed during rolling, stabilize the spring size, and increase the tensile strength and elastic limit of the wire;

[0034] (3) Standing or strong pressure treatment: Grind the two ends of the spring after stress relief annealing, cut the tail, and then perform standing or strong pressure treatment; it can increase the bearing capacity of the static load of the spring by 25%;

[0035] (4) Surface anti-corrosion treatment: galvanize the surface of the formed spring, paint it with oil or paint, inspect and pack it. This step imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com