Semi-automatic assembling tool for automobile inward-opening wrench

A semi-automatic technology for assembling tooling, applied in measuring devices, metal processing, manufacturing tools, etc., it can solve the problems of broken internal wrench products, unfavorable pin assembly, high work intensity, etc., so as to reduce the work intensity of employees and improve assembly. Efficiency and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

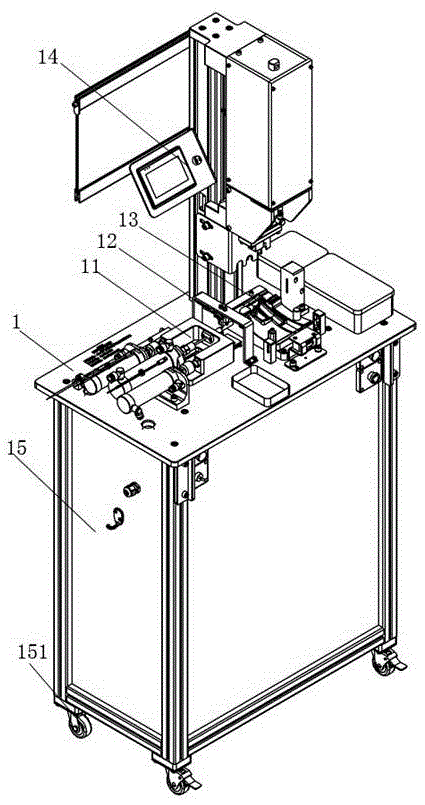

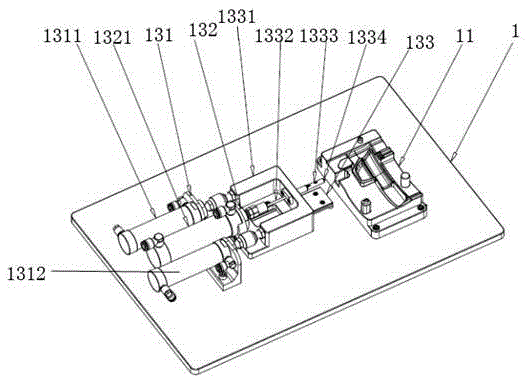

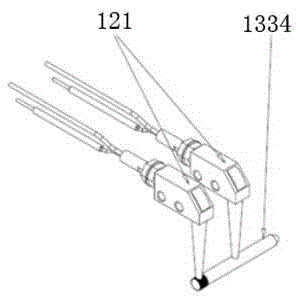

[0015] Such as figure 1 with figure 2 Semi-automatic assembly tooling for automobile internal opening wrench, including work surface 1, which is provided with positioning part 11, detection part 12 and progressive driving part 13, and detection part 12 is provided with knurling detection sensor 121, shaft pin length detection sensor, buffer pad detection sensor and buffer ring detection sensor, respectively collect knurling signals for the shaft pin knurled area and the shaft pin polished rod area through two knurl detection sensors, and the shaft pin length and buffer ring are respectively passed through the shaft pin length detection sensor and The buffer ring detection sensor is used for detection, and the buffer pad is detected by the buffer pad detection sensor. The current signals collected by all sensors are output to the PLC for processing. Tightening mechanism, alarm 141, touch screen 142 and blowing nozzle 143, described compacting mechanism comprises compacting cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com