Resin CBN grinding wheel for grinding plane of control valve bush of fuel spray nozzle

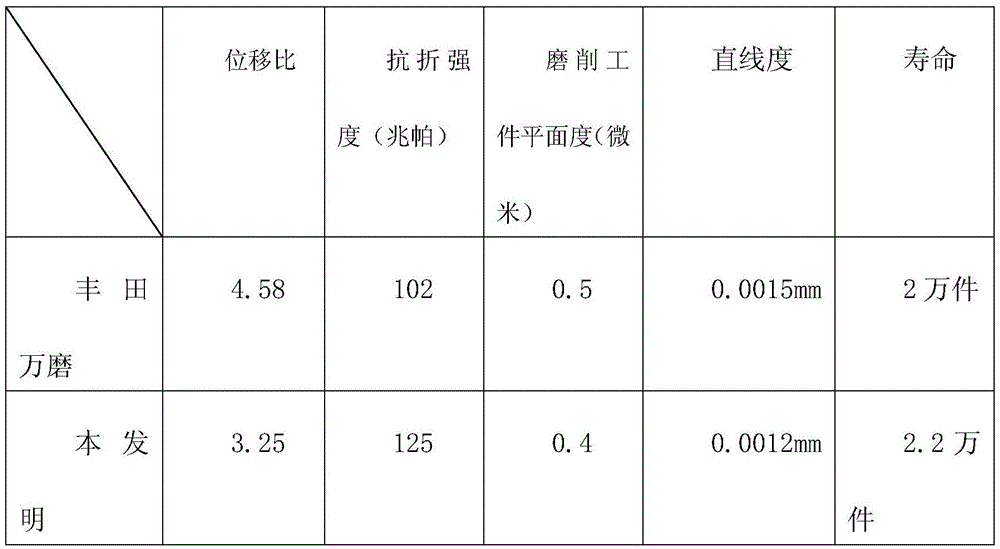

A technology for controlling valve sleeves and fuel injectors, which is applied in abrasives, manufacturing tools, metal processing equipment, etc., can solve the problems of small grinding area of fuel injector control valve sleeves, failure to meet consistency requirements, and high precision requirements, and achieve Long trimming cycle, long service life, and the effect of ensuring shape consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] 1. Prepare the matrix according to the general method;

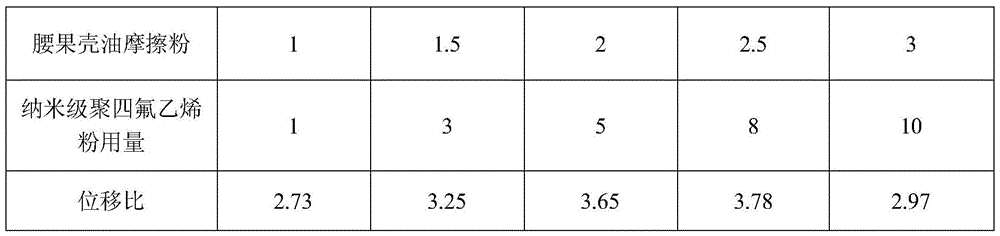

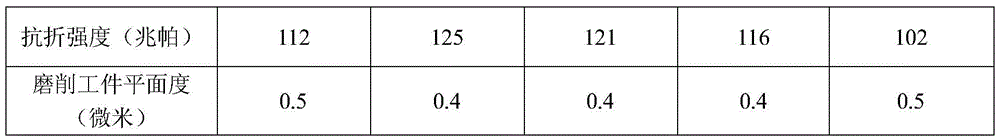

[0009] 2. Preparation of the working abrasive layer; the composition of the working abrasive layer is a resin bond and a mixed filler; the resin bond is an ultrafine polyimide resin; the mixed filler is calculated by volume ratio: particle diameter 10 μm super Fine montmorillonite powder 15, nano-sized SiO25 with a particle size of 0.04 μm, nano-sized polytetrafluoroethylene powder with a particle size of 0.05 μm 1, cashew nut shell oil modified friction powder 1 with a particle size of 10 μm; diamond 7, CBN20.

[0010] Prepare the working abrasive layer and the substrate as a whole according to the general method, that is, the CBN grinding wheel;

Embodiment 2

[0012] 1. Prepare the matrix according to the general method;

[0013] 2. Preparation of the working abrasive layer; the composition of the working abrasive layer is a resin bond and a mixed filler; the resin bond is an ultrafine polyimide resin; the mixed filler is by volume ratio: a particle diameter of 15 μm super Fine montmorillonite powder 13, nano-sized SiO28 with a particle size of 0.04 m, nano-sized polytetrafluoroethylene powder with a particle size of 0.04 μm 3, cashew nut shell oil modified friction powder with a particle size of 12 μm 1.5; diamond 8, CBN25.

[0014] Prepare the working abrasive layer and the substrate as a whole according to the general method, that is, the CBN grinding wheel;

Embodiment 3

[0016] 1. Prepare the matrix according to the general method;

[0017] 2. Preparation of the working abrasive layer; the composition of the working abrasive layer is a resin bond and a mixed filler; the resin bond is an ultrafine polyimide resin; the mixed filler is calculated by volume ratio: particle diameter 10 μm super Fine montmorillonite powder 15, nano-sized SiO210 with a particle size of 0.03 μm, nano-sized polytetrafluoroethylene powder with a particle size of 0.03 μm 5, cashew nut shell oil modified friction powder with a particle size of 10 μm 2; diamond 5, CBN30.

[0018] Prepare the working abrasive layer and the substrate as a whole according to the general method, that is, the CBN grinding wheel;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com