Method for reinforcing woody composite honeycomb panel by glass fiber cloth

A technology of glass fiber cloth and honeycomb panels, which is applied to chemical instruments and methods, glass/slag layered products, wood layered products, etc., can solve the problems of low strength of honeycomb panels, achieve enhanced mechanical properties, expand the scope of use, The effect of alleviating the shortage of timber resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

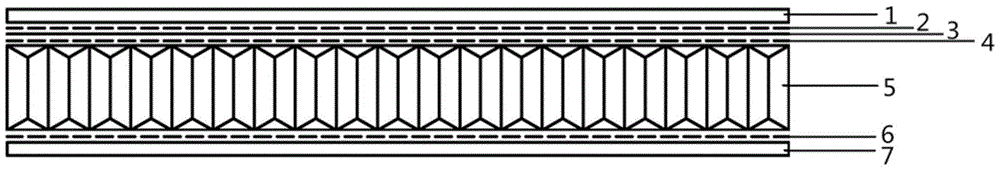

[0016] Step 1. In this embodiment, firstly, the glass fiber cloth with a thickness of 0.1-0.2 mm is pasted with epoxy resin and curing agent to a honeycomb board with a thickness of 10-15 mm. The stiffness of the honeycomb board is 100-200 (g*cm), Gram weight is 600-800(g / m 2 ). In this embodiment, epoxy resin is used as a binder, ethylenediamine is used as a curing agent, the ratio of epoxy resin to ethylenediamine is 4:1-3:1, and the epoxy resin sizing amount is 300-400g / m 2 , one side sizing;

[0017] Step 2. Then place the honeycomb panel reinforced with glass fiber cloth in a cold press for cold pressing, the cold pressing time is 60-90min, and the pressure is 0.6-1.0Mpa;

[0018] Step 3. After cold pressing, paste the ash veneer with a thickness of 1.0-2.0mm with milky white glue to the surface of the glass fiber cloth reinforced honeycomb board after step 2 cold pressing. The amount of sizing of milky white glue is 170-200g. / m 2 , one side sizing;

[0019] Step ...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the thickness of the glass fiber cloth is 0.18mm, the thickness of the honeycomb board is 12mm, the ratio of epoxy resin to ethylenediamine is 3:1, the second The cold pressing time for one time is 7min, and the pressure is 0.8Mpa; the thickness of the ash veneer is 1.2m, and the sizing amount of latex glue is 180g / m 2 , the thickness of poplar veneer is 1.5mm, and the sizing amount of latex glue is 200g / m 2 , the second cold pressing time is 40min, and the pressure is 0.5Mpa.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 2 is: step (1) the ratio of epoxy resin to ethylenediamine is 3:1, and other steps are the same as Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com