Dumper for transporting plate-type ballast beds

A technology of dump trucks and transportation boards, which is applied to vehicles used for freight transportation, transportation objects, vehicles with wheels, etc. It can solve the problems of no board type ballast bed, etc., and achieve the effects of reducing transportation costs, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

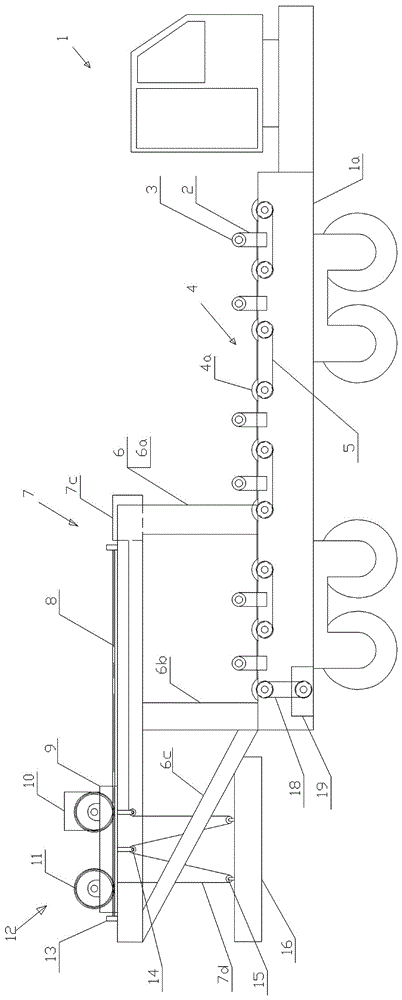

[0024] Such as figure 1 , figure 2 and Figure 5 As shown, a dump truck for transporting a slab track bed provided by the present invention includes a car body 1 and its frame 1a, the frame 1a is provided with a second driving device 19 and an idler unit 4, and the idler unit 4 It consists of a row of idler rollers 4a arranged along the axis of the frame 1a. Each idler 4a is rotatably matched with the frame 1a. Adjacent idler rollers 4a are connected and matched by a sprocket transmission mechanism 5. At least one of the idler rollers 4a and the second driving device 19 are connected and cooperated through the pulley transmission mechanism 18; a group of fixed seats 2 are uniformly distributed on both sides of the frame 1a, and the fixed seats 2 are provided with a second jacking device 3 with a horizontal axis. The vertical plane where the axes of the two jacking devices 3 are located is perpendicular to the axial direction of the vehicle frame 1a, and one end of the secon...

Embodiment 2

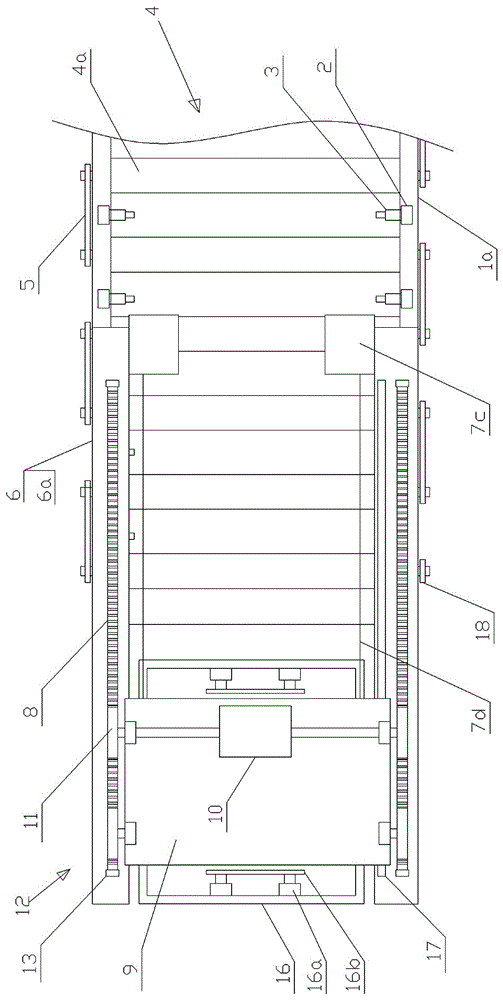

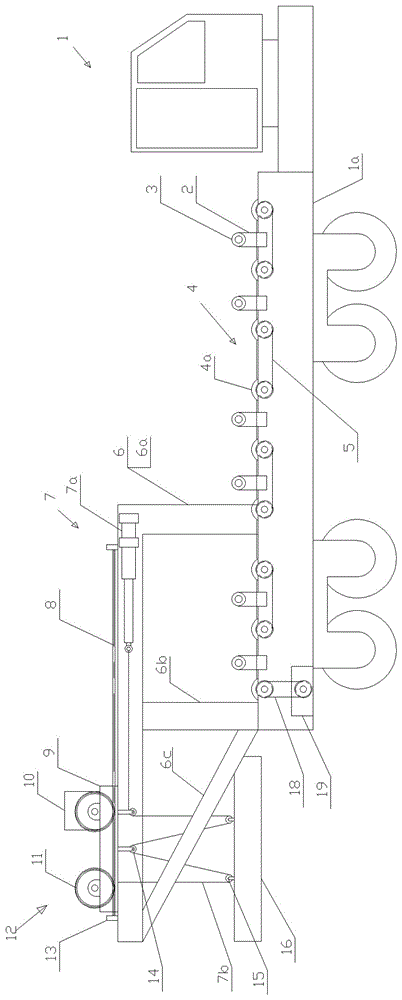

[0026] Such as image 3 , Figure 4 and Figure 5 As shown, a dump truck for transporting slab track beds provided by the present invention includes a car body 1 and a vehicle frame 1a thereof, and the vehicle frame 1a is provided with a second driving device 19 and an idler unit 4, and the idler unit 4 consists of It consists of a row of idler rollers 4a arranged along the axis of the frame 1a. Each idler 4a is rotatably matched with the frame 1a. Adjacent idler rollers 4a are connected and matched by a sprocket transmission mechanism 5. At least one idler 4a It is connected and matched with the second driving device 19 through the pulley transmission mechanism 18; a group of fixed seats 2 are uniformly distributed on both sides of the vehicle frame 1a, and the fixed seats 2 are provided with a second jacking device 3 with a horizontal axis. The vertical plane where the jacking device 3 axis is located is perpendicular to the axial direction of the vehicle frame 1a, and one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com