Device and process for mixing micro-alga and rice husk to produce oil by aid of continuous hydrothermal method

A technology of continuous mixing and hydrothermal method, which is applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oils. It can solve problems such as difficult production and utilization, and achieve high water content, high calorific value, and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

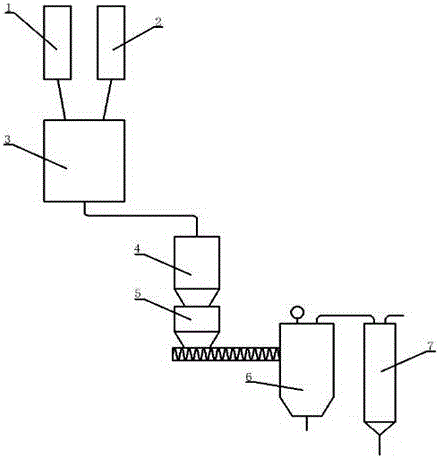

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings: a device and process for continuous hydrothermal oil production by mixing microalgae and rice husks. Tank 4, lower storage tank 5, hydrothermal reaction kettle 6, gas-liquid separator 7. Their connection mode is that the microalgae feeding bin 1 is connected in parallel with the rice husk feeding bin 2 and then connected with the stirring tank 3, the stirring tank 3 is connected with the upper-level storage tank 4, the upper-level storage tank 4 is connected with the lower-level storage tank 5, and the lower-level storage tank The feed tank 5 is connected to the hydrothermal reaction kettle 6 through a screw feeding device, the top of the hydrothermal reaction kettle 6 is connected to the top of the gas-liquid separator 7 , and the bottom of the hydrothermal reaction kettle 6 is connected to the middle of the gas-liquid separator 7 .

[0031] There is an electronic val...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap