Advance borehole frame based on adjustable triangular support

An advanced drilling and triangular technology, which is applied in the direction of drilling equipment, earthwork drilling, supporting devices, etc., can solve the problems of affecting the tunnel construction progress, low drilling efficiency, high labor intensity, etc., and achieves high practical value and simple front and rear adjustment. , The effect of low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

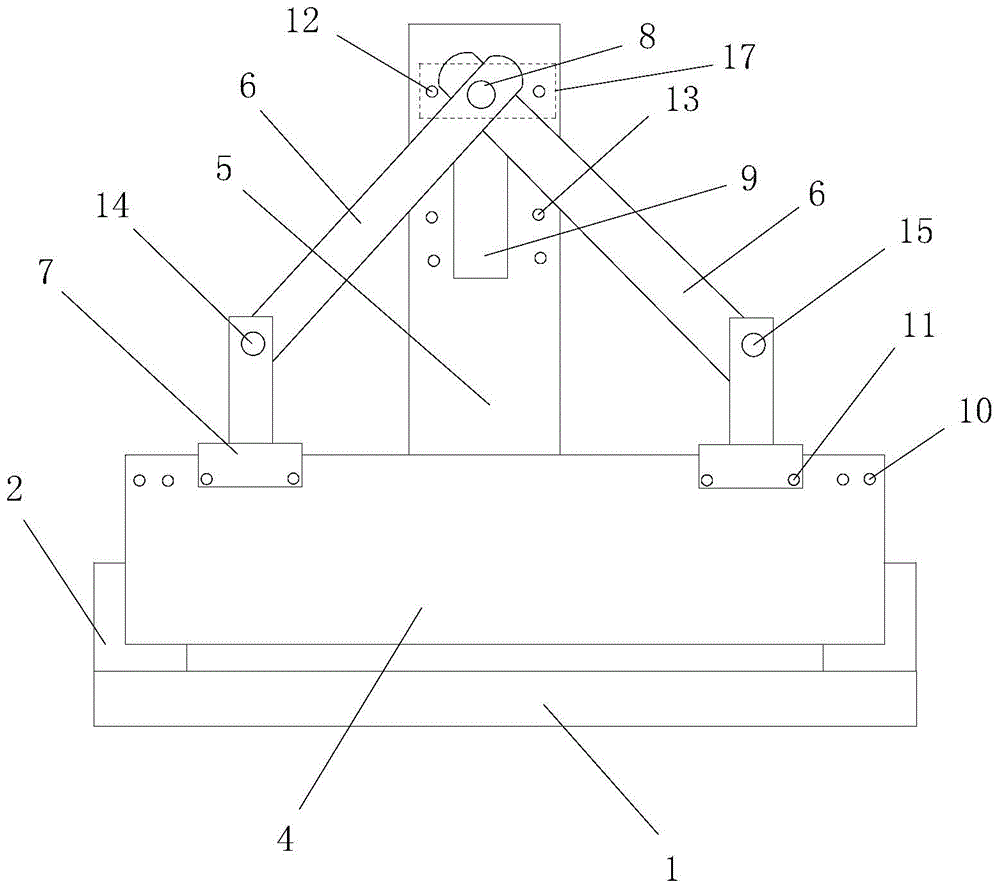

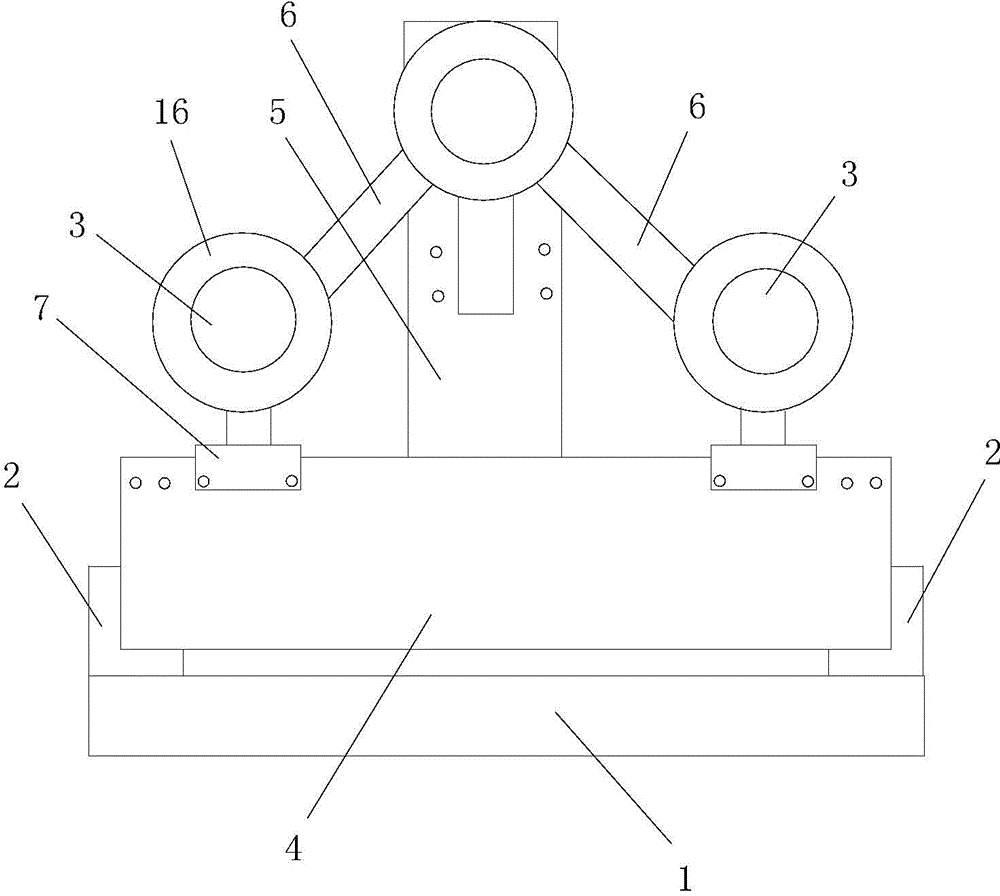

[0024] Such as figure 1 , figure 2 As shown, the present invention includes a horizontal workbench 1 located at the rear side of the tunnel face under construction, two horizontal steel rails 2 respectively installed on the left and right sides of the upper part of the horizontal workbench 1 and moving back and forth along the two horizontal steel rails 2 And for the drilling rig installation frame installed by the horizontal drilling machine 3, the horizontal workbench 1 is arranged along the longitudinal extension direction of the tunnel being constructed, and the two horizontal rails 2 are arranged along the length direction of the horizontal workbench 1. The rig mounting frame includes a rectangular bracket 4 whose bottom is clamped between the two horizontal rails 2 and moves back and forth along the two horizontal rails 2, a vertical mounting plate 5 installed above the middle of the rectangular bracket 4, two A diagonal connecting rod 6 installed on the left and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com