Nonimplanted system and method for monitoring sand production rate of thick oil well

A monitoring system and technology for sand production, which are used in surveying, earthmoving, wellbore/well components, etc. to facilitate construction and maintenance and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

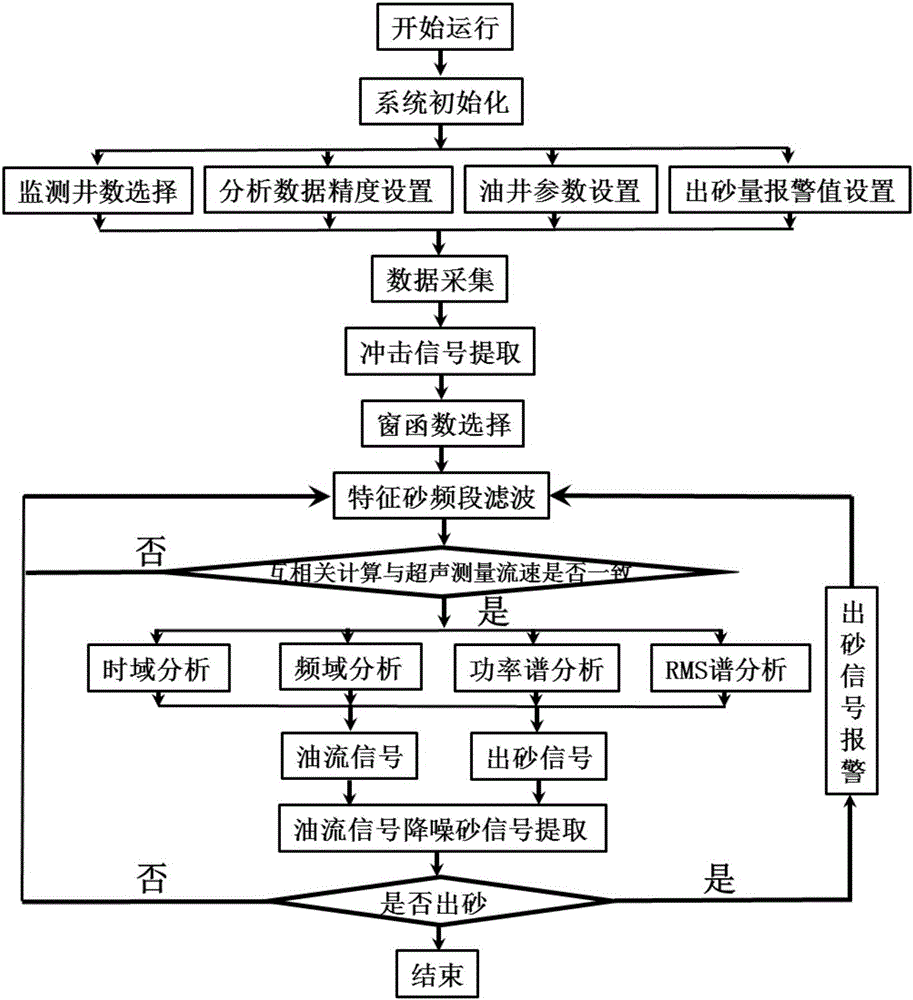

[0047] In the process of heavy oil production, sand-carrying crude oil flows in the oil production pipeline. When flowing through the elbow, due to the sudden change of fluid flow direction, the sand and gravel directly impact on the pipe wall under the action of inertia to generate vibration. The greater the amount of grit, the greater the number of vibrations generated at the pipe wall. The larger the particle size of the gravel, the greater the vibration intensity produced at the pipe wall.

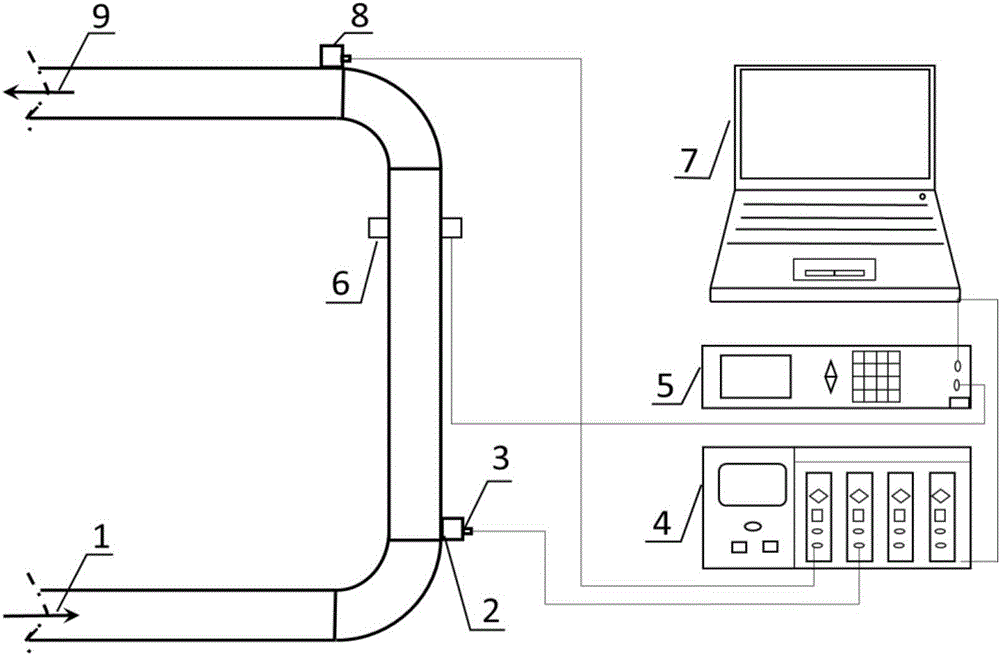

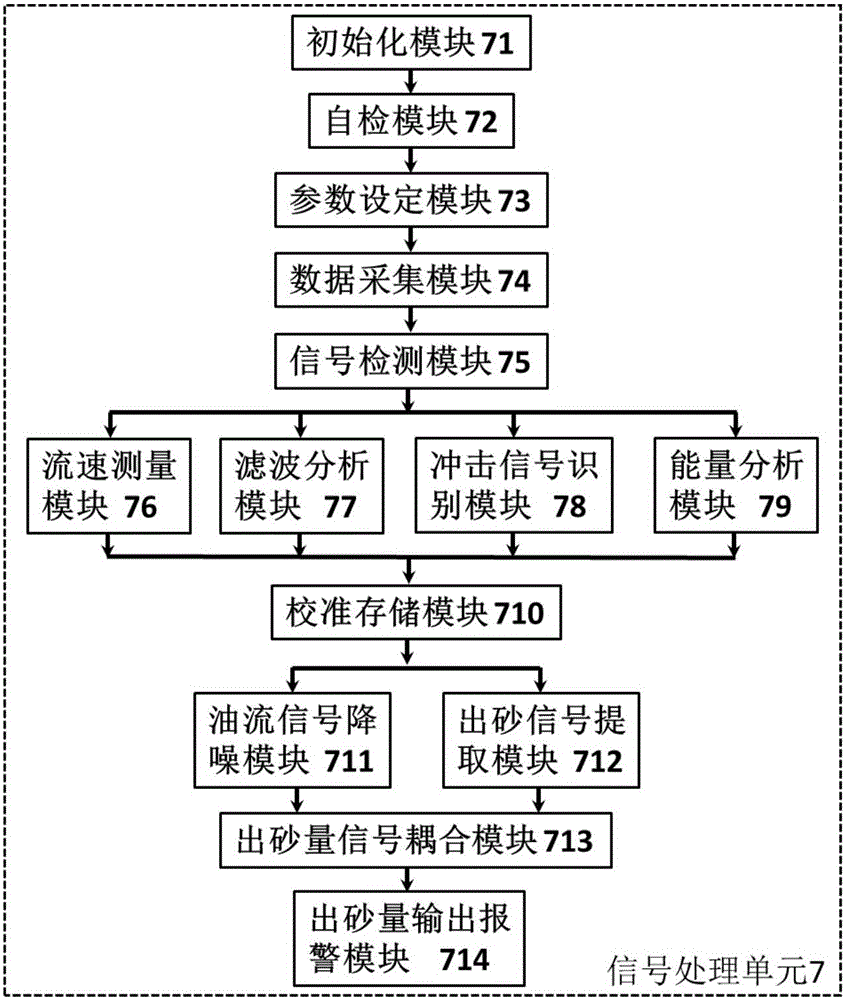

[0048] Such as figure 1As shown, the heavy oil well sand production monitoring system provided by the present invention includes determining the fluid flow direction in the oil production pipeline, 1 is the oil inflow inlet, and 9 is the oil outflow outlet. According to the fluid flow direction, select the installation position 2 of the sensor near one pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com