Split starting shield machine and temporary slag discharge system

A technology of split originating and shield machines, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problem that the split originating shield machine cannot normally complete the slag discharge operation, and achieves convenience, front and rear height consistency, Easy to assemble and disassemble, to achieve the effect of stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and an embodiment.

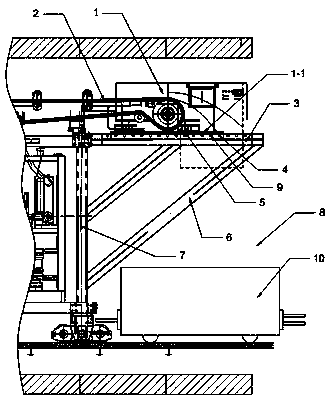

[0020] The present invention mainly includes a belt conveyor 1 and a slag truck 10, the belt conveyor 1 is detachably placed behind the last trolley 7 of the shield machine starting from the split, and the belt 2 on the belt conveyor 1 The direction is along the longitudinal direction of the tunnel 8, and the slag is transported to the slag truck 10 below the belt conveyor 1 by the belt 2.

[0021] The installation and working process of the above-mentioned device is as follows: firstly, the head of the shield machine starting from the separate body first enters the tunnel 8, and then according to the length of the tunnel 8, the number of trolleys connected to the head is determined, generally 1 Then, install this slag discharge system on the last trolley 7. During installation, the feeding direction of the belt 2 on the belt conveyor 1 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com