Solid-liquid-gas three-state cooperative garbage pyrolysis treatment system

A treatment system and garbage treatment technology, which is applied in the field of solid-liquid-gas three-state collaborative garbage pyrolysis treatment system, can solve the problems of low efficiency of domestic garbage treatment, achieve the effects of avoiding explosion risks, saving costs, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

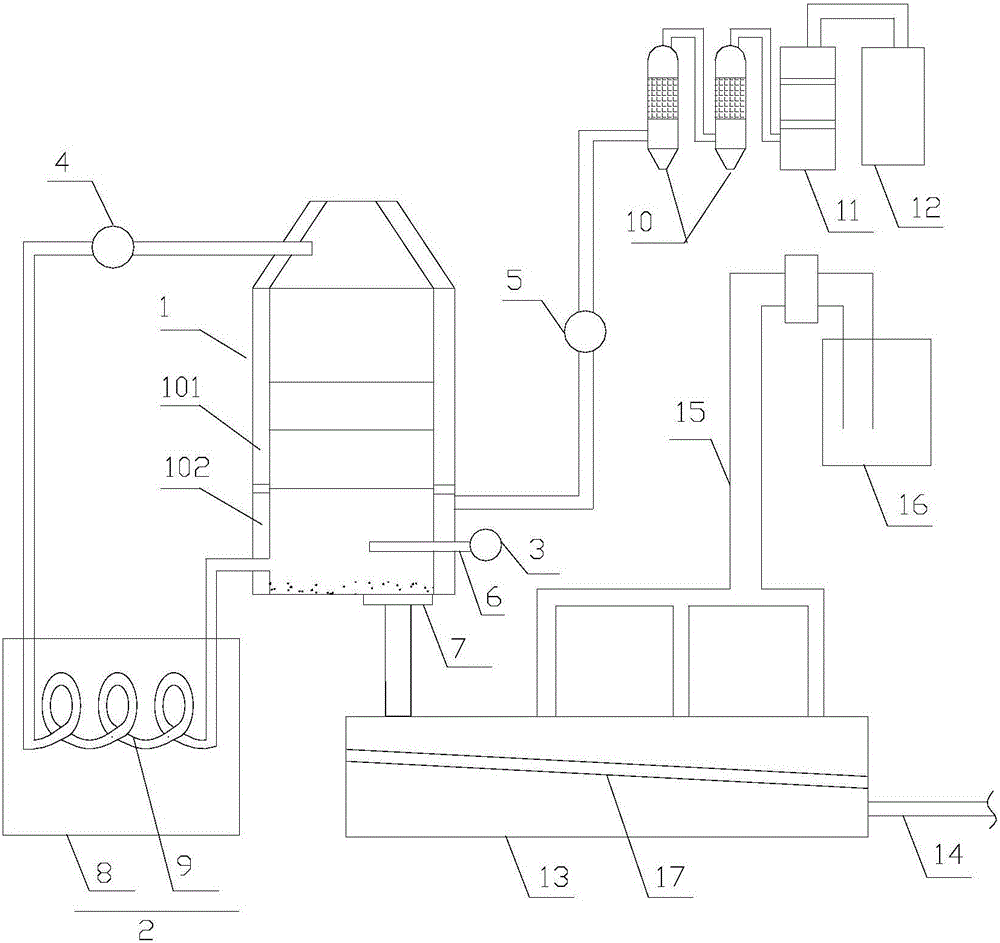

[0027] refer to figure 1 , a solid-liquid-gas three-state cooperative garbage pyrolysis treatment system proposed by the present invention, comprising: a garbage treatment furnace 1, a water filter device 2, a blower 3, a first induced draft fan 4, a second induced draft fan 5, a gas purification mechanism and Slag recovery mechanism.

[0028] The top of the garbage disposal furnace 1 is provided with a feed port for pouring garbage into the garbage disposal furnace 1. After the bottom of the garbage disposal furnace 1 is ignited, the garbage is poured into the garbage disposal furnace 1. The garbage disposal furnace 1 can burn the garbage from the bottom. The garbage disposal furnace 1 According to the temperature change, it is divided into oxidation layer, reduction layer, dry distillation layer and drying layer from bottom to top. The waste in the oxidation layer is burned at high temperature, and the decomposable substances in the waste in the reduction layer are decompose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com