Testing stand for detecting rotating rock breaking energy consumption of cutter

A technology of rotary rock breaking and test bench, which is applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problem of inability to separate and measure energy consumption, and achieve a simple and effective implementation scheme, reliable working principle, and structure. Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

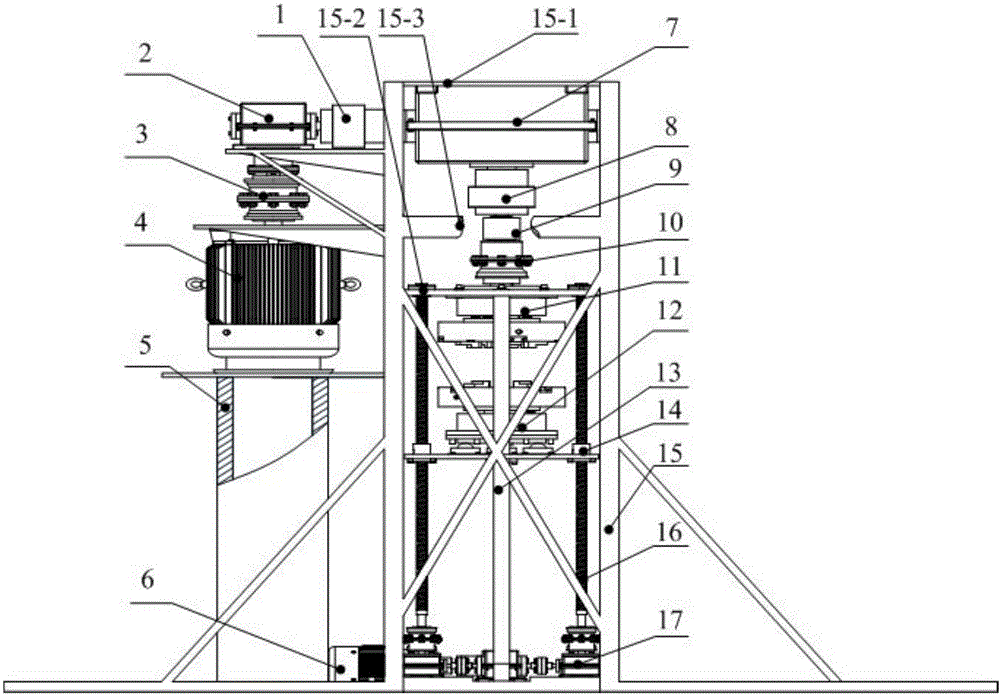

[0020] The present invention will be further explained below in conjunction with the accompanying drawings.

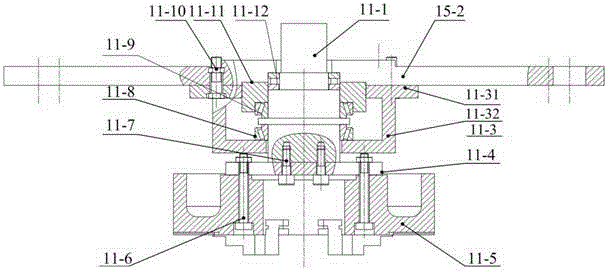

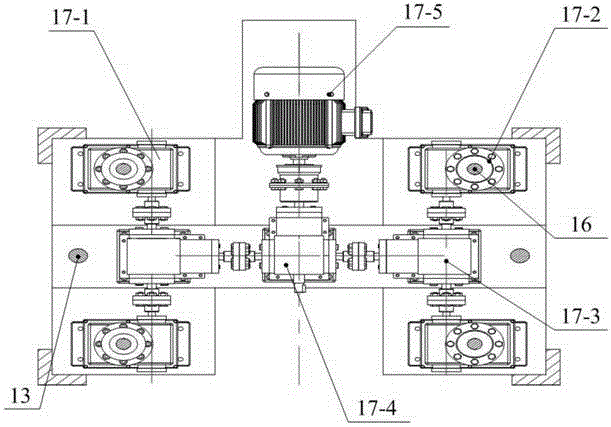

[0021] Such as figure 1 As shown, a kind of tool rotary rock breaking energy consumption detection test bench, including test bench fixed frame 15, first motor 4, worm gear reducer 7, dynamic torque sensor 9, upper rotary table 11, feed mobile table 12 and feed Mobile drive mechanism.

[0022] The test bench fixture 15 is provided with a top support plate 15-1 and a middle support plate 15-2, the worm gear reducer 7 is fixed on the top support plate 15-1, and the output shaft of the worm gear reducer 7 is arranged vertically downward, and its input The axis is in the horizontal direction. A motor support base 5 is arranged on one side of the test bench fixing frame 15, and the first motor 4 is vertically fixed on the motor support base 5. The output shaft of the first motor 4 is connected to the input shaft of the steering reducer 2 through the first coupling 3 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com