Underground robot communication control system based on wireless sensor network

A wireless sensor and sensor network technology, applied in wireless communication, signal transmission system, network topology, etc., can solve the problems of unusable wireless communication system and affecting the working distance of underground robots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

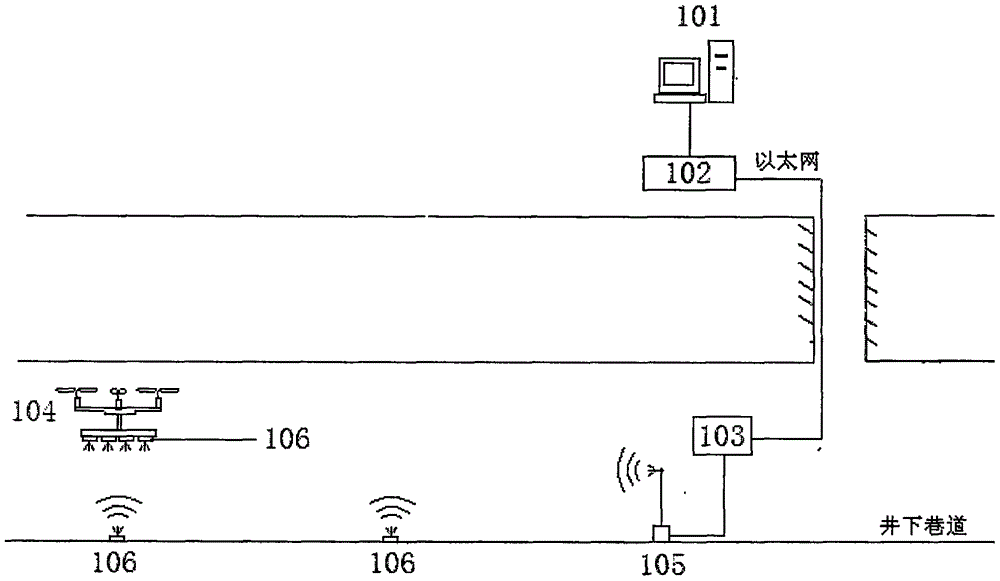

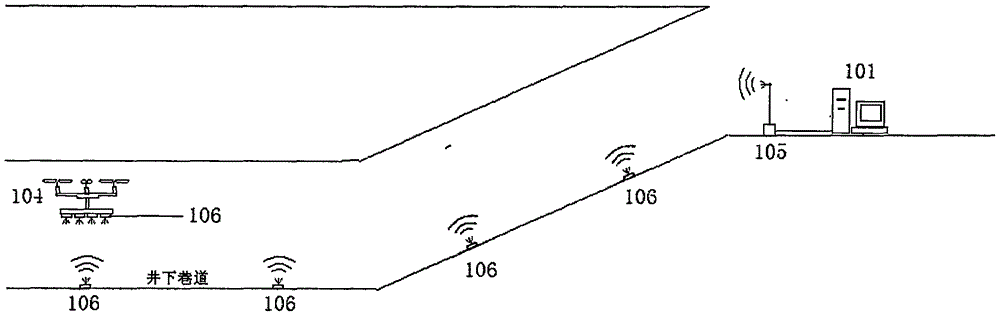

[0023] The specific implementation manner of the communication control system 1 is as figure 1 As shown, the composition includes:

[0024] 1. Robot control equipment (101), responsible for controlling the downhole robot, receiving various data uploaded by the downhole robot through the multi-hop wireless sensor network and Ethernet, including video or image data, various sensor data, and voice data; and multi-hop wireless sensor network to send control data and voice data to the downhole robot.

[0025] 2. Inoue switch (102), responsible for management and data exchange of all devices connected to the Ethernet.

[0026] 3. The downhole switch (103), responsible for data exchange of all devices connected to the Ethernet in the downhole.

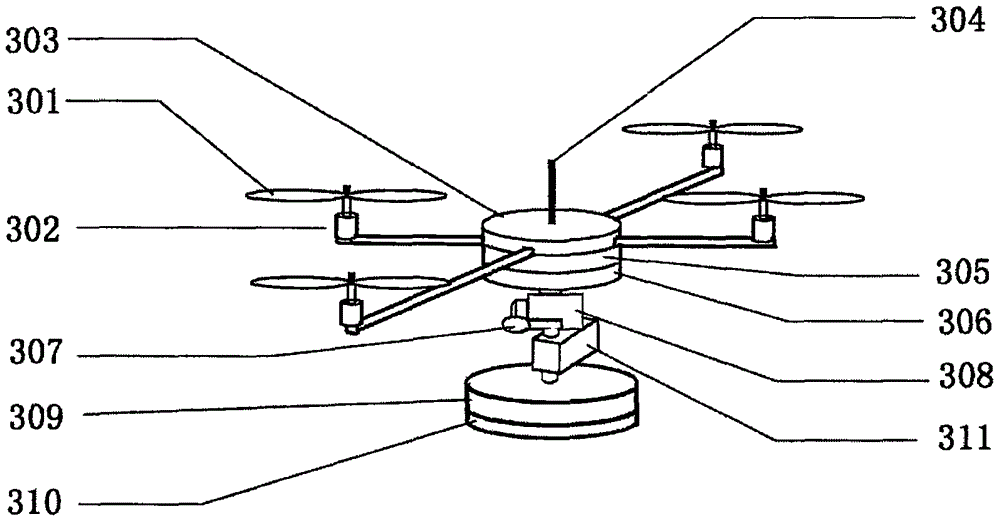

[0027] 4. The underground robot (104) can be a rotor flying robot, or a wheeled, crawler, snake-like robot that travels on the ground, carrying a plurality of Wifi routing devices (106) for distributing nets during travel.

[0028] 5. Wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com