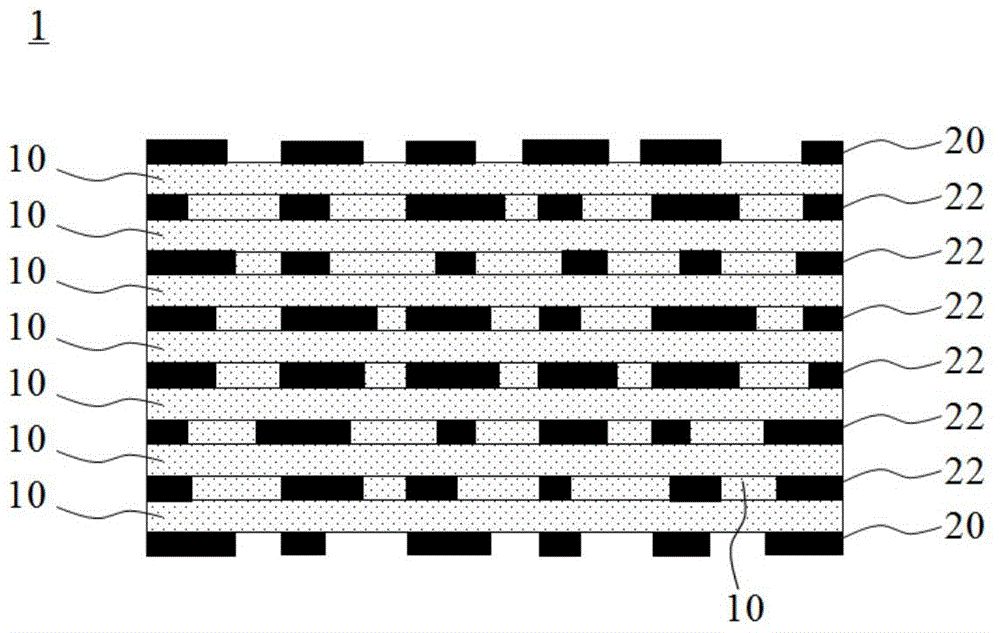

Multi-layer printed circuit boards suitable for layer reduction design

一种多层印刷、电路板的技术,应用在印刷电路、印刷电路、印刷电路零部件等方向,能够解决制程良率降低、成本提高等问题,达到高信号传输特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

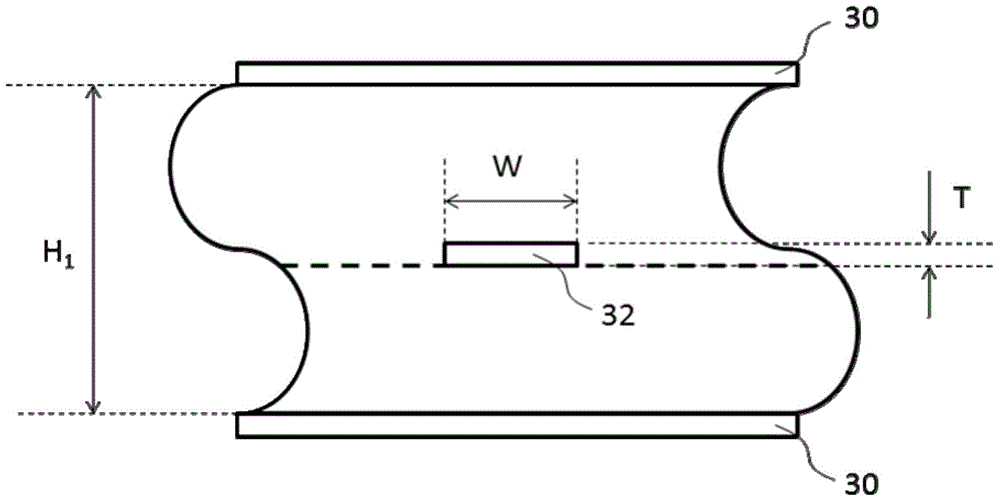

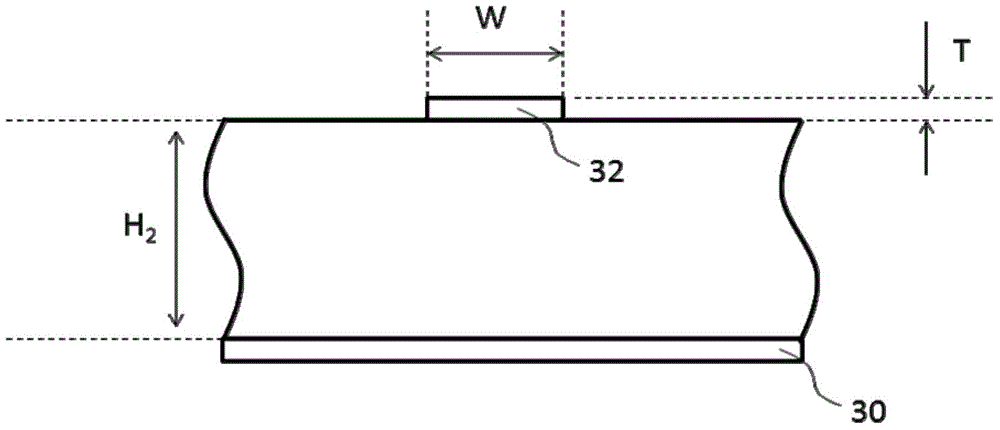

[0050] Example 1 (E1) Use the EM-355 (D) prepreg (E-glass cloth, 1037, resin content 75%) sold by Taiwan Optoelectronics Materials Co., Ltd., and use the existing layer-reducing design of the above-mentioned prepreg as a multi-layer board Fabrication Method An eight-layer circuit board is fabricated. Embodiment 2 (E2) Use the EM-355(D)K prepreg (L-glass cloth, 1037, resin content 75%) sold by Taiwan Optoelectronics Materials Co., Ltd., and use the existing layer-reducing design of the above-mentioned prepreg as a multi-layer The board manufacturing method makes an eight-layer circuit board. Embodiments 3 to 7 (E3-E7) are to mix the components of the low dielectric resin composition of Table 1, Example 3 (A3) evenly to prepare resin composition glue (varnish), and use L-glass cloth (1037) or NE- The glass cloth is impregnated with the glue to make a prepreg (resin content 75%). The above-mentioned prepreg is used to make an eight-layer circuit board with the existing multilay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com