Vacuum distillation method for easily polymerizable compound and method for producing acrylic acid

一种丙烯酸、丙烯的技术,应用在有机化合物的制备、羧酸化合物的分离/纯化、化学仪器和方法等方向,达到防止堵塞的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0101] Similar to the comparative example, the driving steam of the steam ejector was adjusted to 1.0 MPaG, and the operation of the distillation column was performed. The time to CV opening reduction after steam injector cleaning was 3 weeks and 5 weeks without improvement.

Embodiment 1

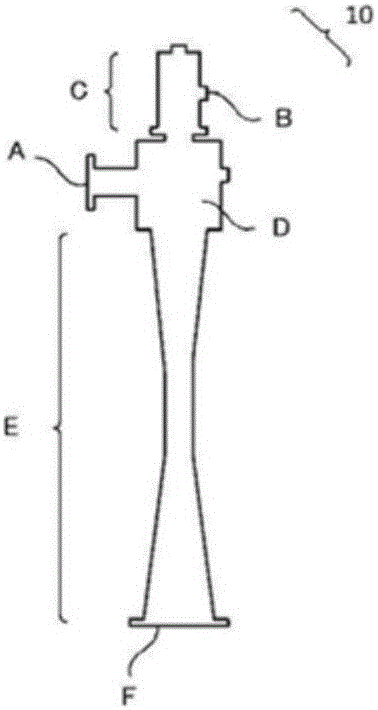

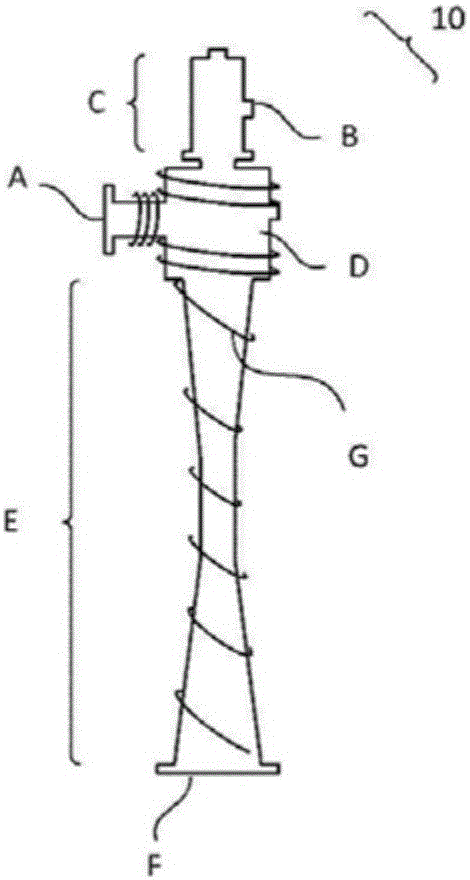

[0103] Such as image 3 As shown, the distillation column is operated while heating the outer surfaces of the suction port of the first-stage and second-stage steam injectors, the outer surface of the vacuum part, and the outer surface of the diffuser using steam heating companion pipes. Other than that, it carried out similarly to the said comparative example 1. The steam used for steam heating with pipe is 0.3MPaG. The temperature of the outer surface of the suction port of the steam injector is 70-85°C. During 11 months of continuous operation, no significant reduction in CV opening was found. It should be noted that when the operation continued for 6 months, the piping of the steam heating trace was kept in its original state, and the steam for heating the trace was stopped for 2 days, and then the supply of steam was restarted, but it was not confirmed before and after. Significant difference. From the above results, it can be seen that heating the outer surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com