Induction module for an internal combustion engine

A technology of air intake and exhaust gas, which is applied in the direction of fuel air intake, internal combustion piston engine, combustion engine, etc., can solve the problems of intercooler blockage, intercooler pollution, invasion of intercooler or other components, etc., and achieve improvement efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

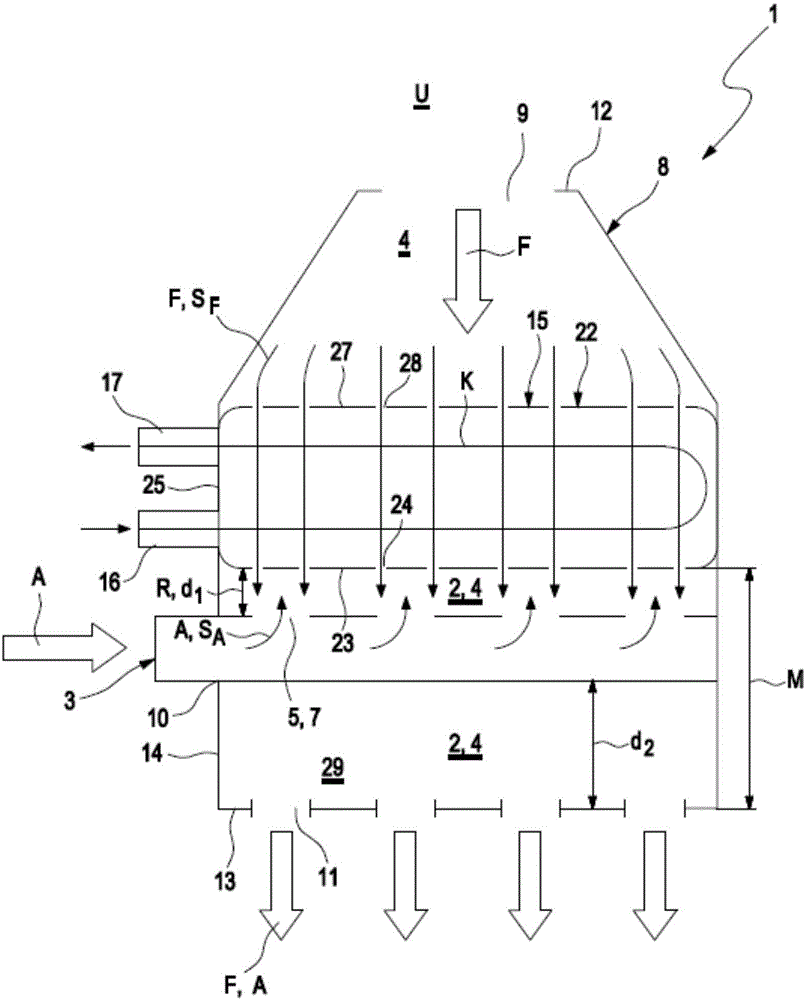

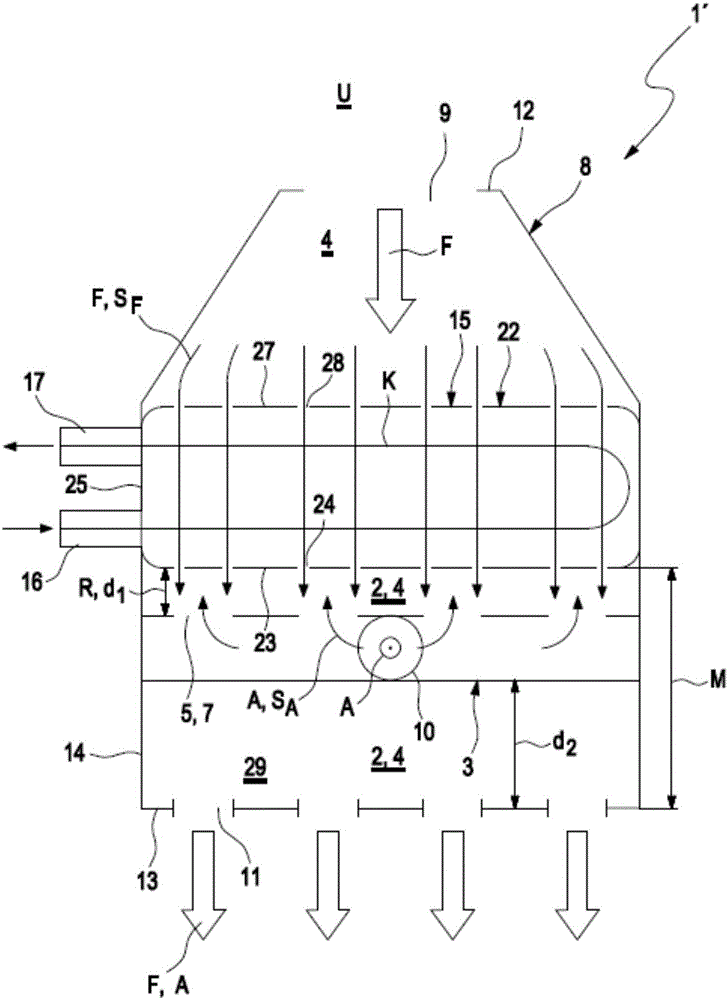

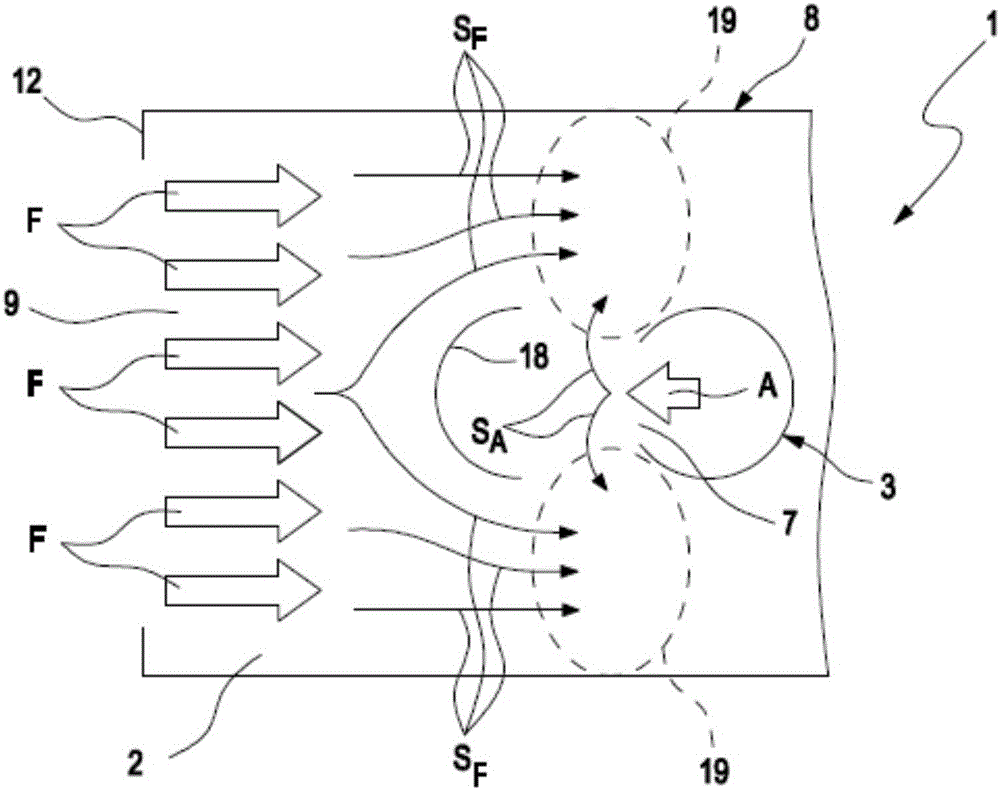

[0044] Figure 1a An example of an air intake module 1 according to the invention with integrated exhaust gas recirculation is shown schematically. Said air intake module 1 comprises a plastic housing 8 defining a housing interior 4 . The housing 8 comprises a first housing wall 12 with at least one air inlet 9 and a second housing wall 13 with at least one fluid outlet 11 . Charge air charged by the exhaust gas turbocharger or relatively fresh air F can enter the housing interior 4 via the air inlet 9 . In the housing interior 4 , an intercooler 15 is arranged, through which the fresh air F guided into the housing interior 4 flows. In this way, the fresh air F, usually charge air heated by the compression of the exhaust turbocharger, is cooled by the intercooler 15 .

[0045] The air intake module 1 additionally has a mixing chamber 2 which is part of the housing interior 4 and is delimited by an intercooler 15 and a second housing wall 13 . Arranged in the mixing chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com