Roller type rice fertilization and direct seeding combinational machine

A combined machine and rice technology, which is applied in the fields of fertilizer and seeding equipment, planting methods, and agricultural gas emission reduction, can solve the problems of inability to complete sowing and fertilization simultaneously, poor operation effect and quality, and low rice yield, so as to increase production Significant effect, less power consumption for operation, and high utilization rate of chemical fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

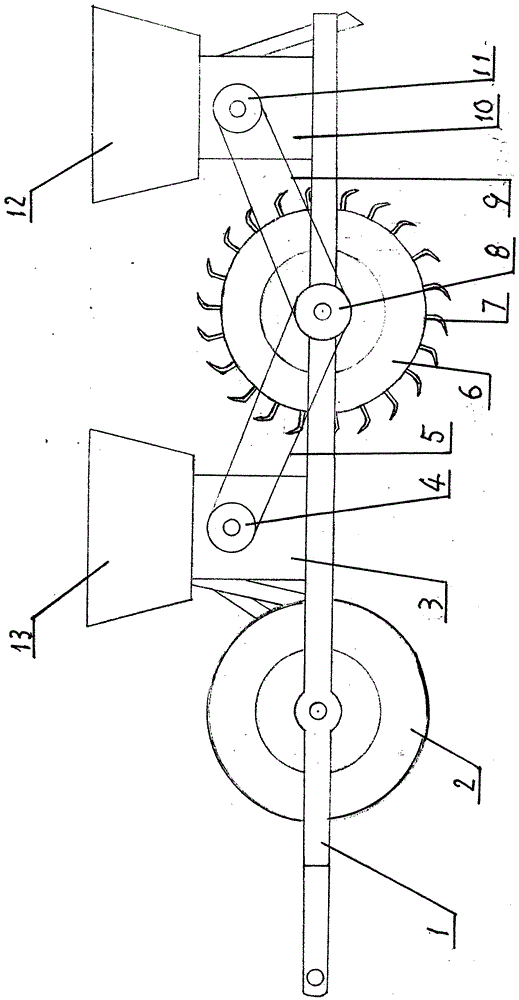

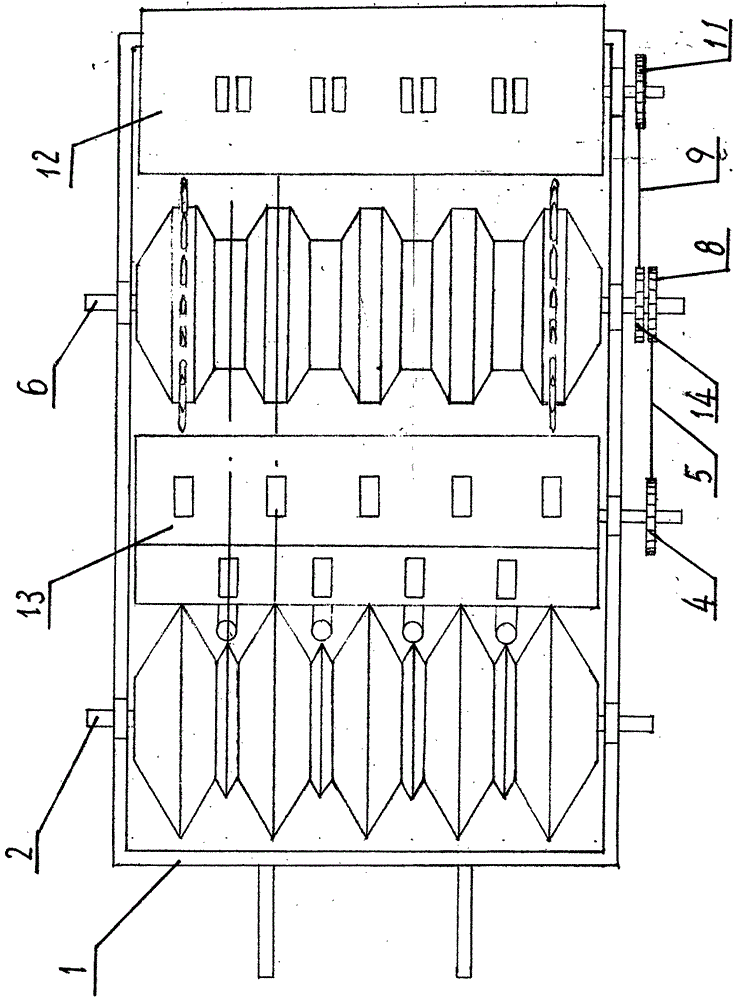

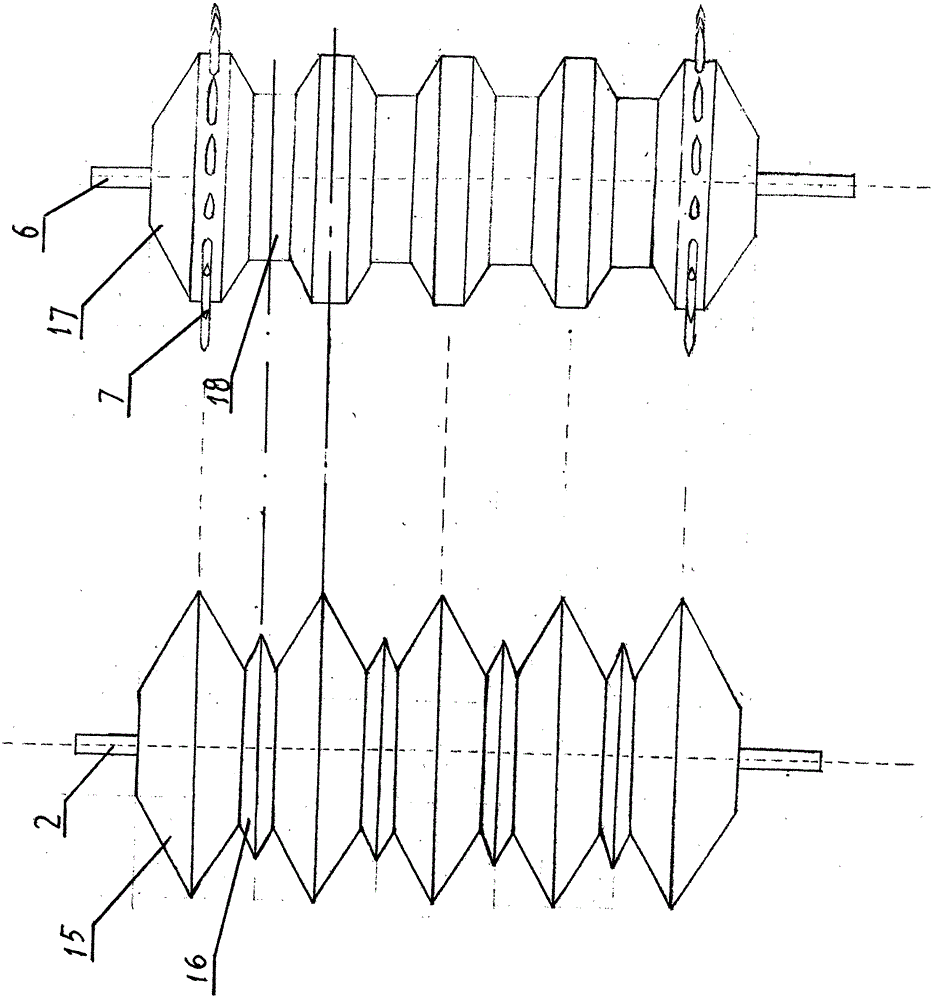

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A kind of roller type paddy fertilization, direct seeding combined machine, on the frame 1, the fertilizer box 13 with the fertilizer applicator 3 and the seed box 12 with the seed meter 10 are installed, and on the frame 1, it is rotatable successively from the front to the bottom. Afterwards, the W-shaped rolling type fertilizer ditch ditching and ridging roller assembly 2 and the trapezoidal rolling type seed platform forming and power driving roller assembly 6 are assembled, and the trapezoidal rolling type seed platform forming and power driving roller assembly 6 is assembled. The first driving sprocket 8 and the second driving sprocket 14 are fixed on the 6, the first chain 5 is set on the first driving sprocket, 8 and the first sprocket 4 on the fertilizer applicator 3, and the second chain 9 is set On the second driving sprocket 14 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com