A compact exhaust gas treatment device

A compact technology for exhaust gas treatment, applied in gas treatment, air quality improvement, liquid separation agent, etc., can solve the problems of large footprint and easy plugging of packing, and achieve small footprint and avoid pressure drop increase , The effect of smooth equipment management process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

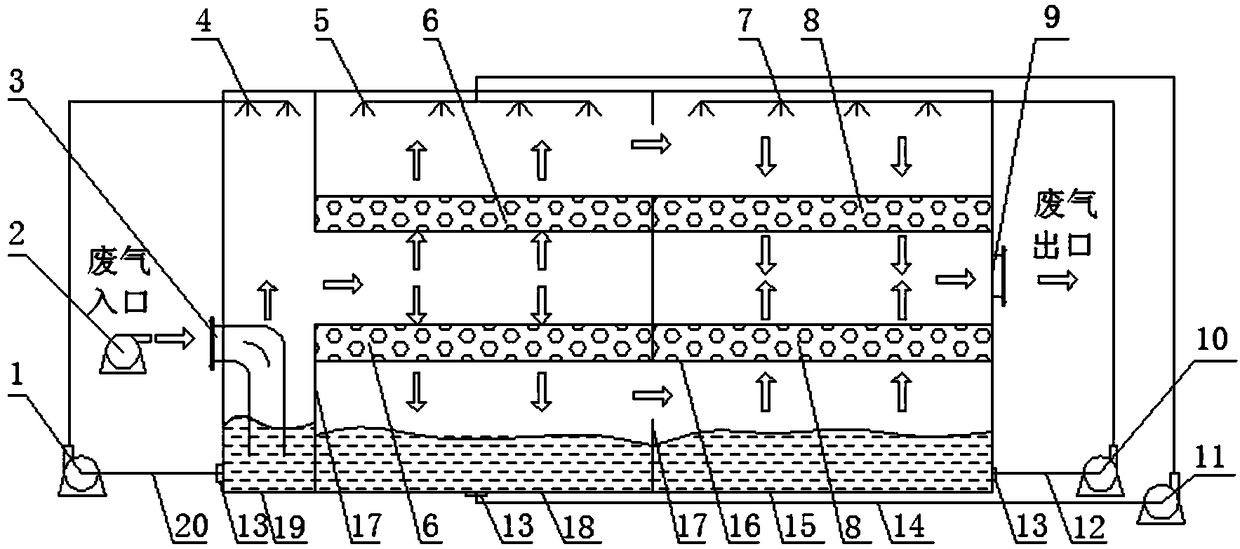

[0031] The following combination figure 1 The exhaust gas treatment device in the paper will be described in detail.

[0032] see figure 1 , the exhaust gas treatment device includes a spray washing section and a biological filtration section, and the spray washing section box body and the biological filtration section box body together form a box body, wherein the entrance on the spray water washing section box body 19 is the equipment air inlet 3 , is connected with blower blower 2 that blows into waste gas, and the outlet of described spray washing section casing is connected with the entrance of biological filtration section casing, and the outlet on the biological filtration section casing is equipment air outlet 9.

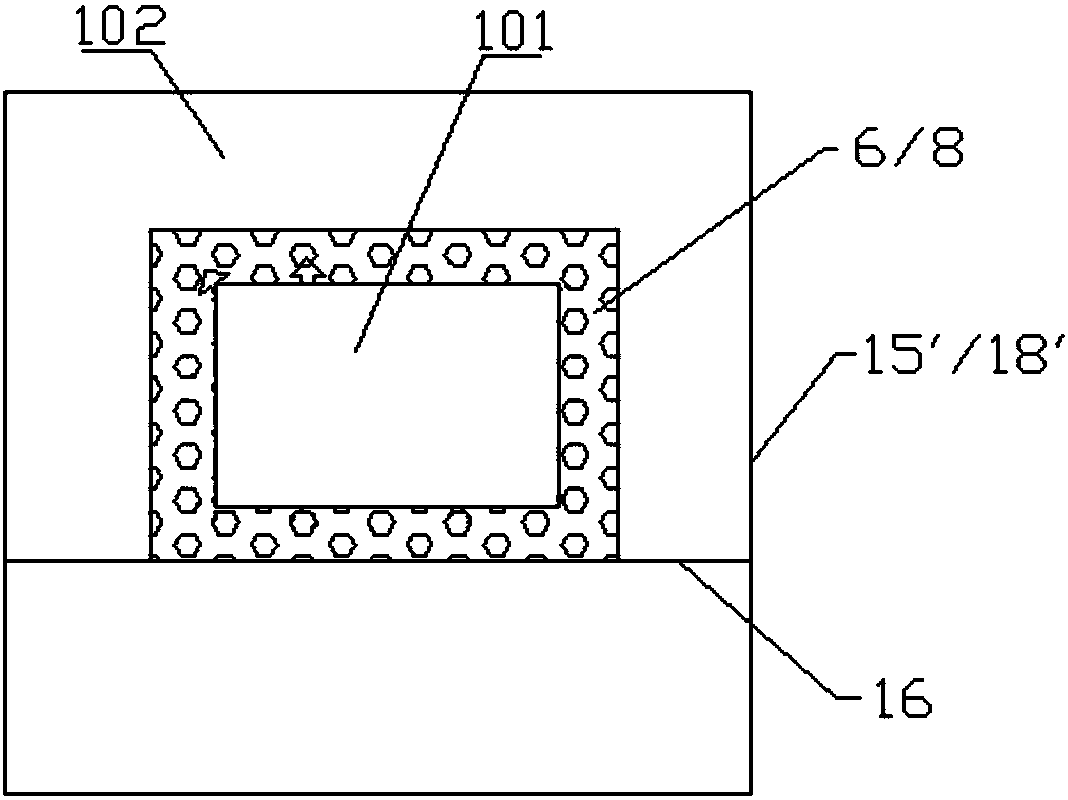

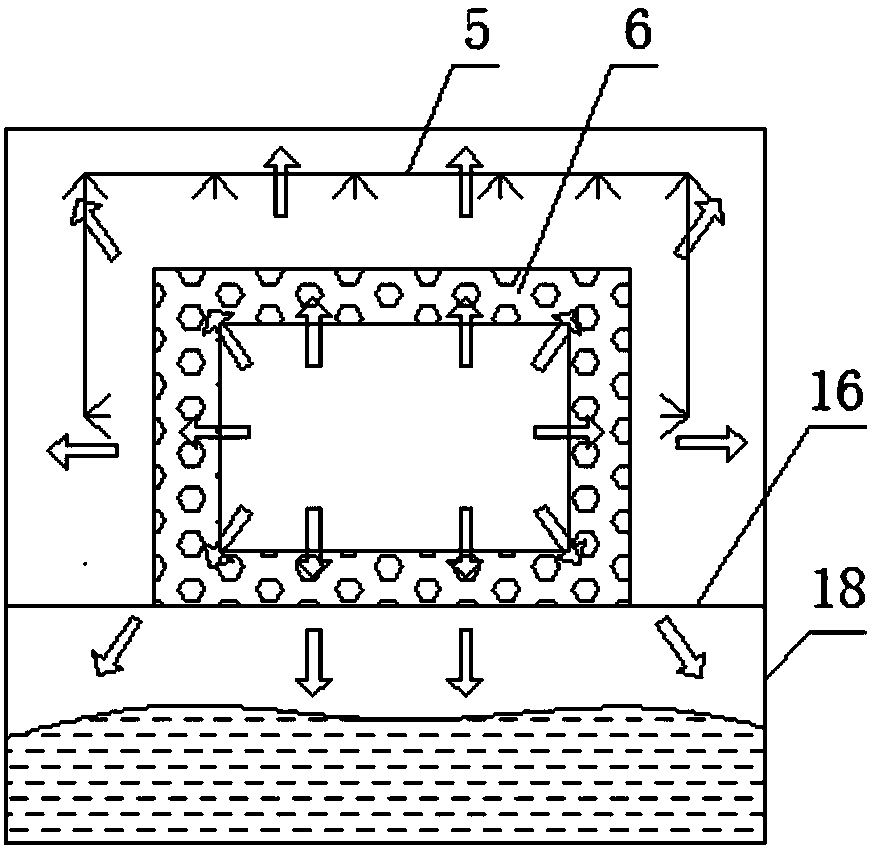

[0033] The biological filtration section is composed of two stages of biological purification modules connected in series, including the first-stage biological filtration section box 18, the first biological filler module 6, the second spray pipe and nozzle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com