Fully-automatic grinder for screw rod nut inner thread

A technology for screw nuts and internal threads, which is applied in the field of automatic grinding machines, can solve the problems of large cutting volume and unfavorable thread precision control, and achieve the effects of high machining accuracy, improved machining quality, and high machined surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

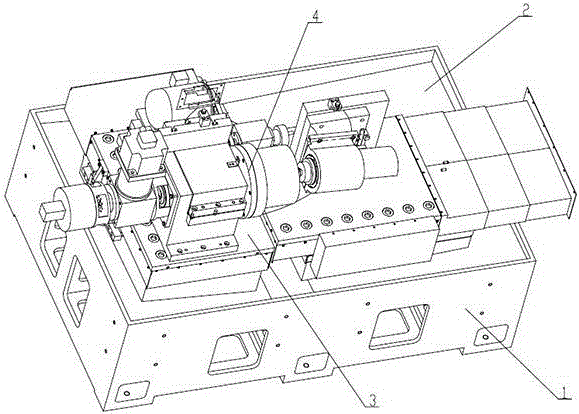

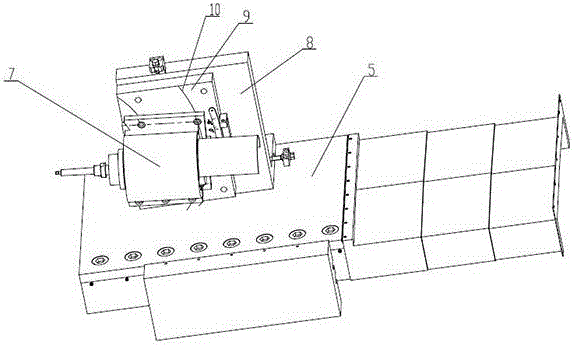

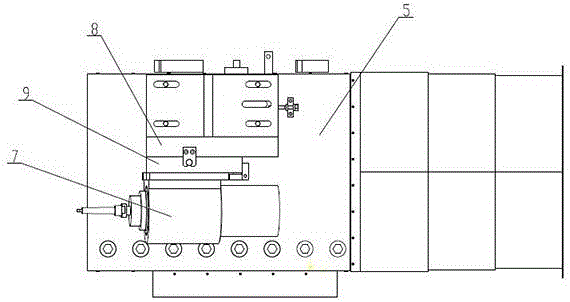

[0024] Such as Figure 1-4 As shown, the fully automatic grinding machine of a kind of lead screw nut internal thread provided in the present embodiment, it specifically comprises:

[0025] An equipment bed part 1 provided with an installation base 2;

[0026] A workpiece feed part located on the installation base surface 2 of the above-mentioned equipment bed part 1, the workpiece feed part includes an installation base surface 2 installed on the above-mentioned equipment bed part 1, and the supporting plate A first pallet mechanism 3 capable of reciprocating movement in a fixed direction and a workpiece clamping mechanism 4 mounted on the pallet surface of the first pallet mechanism 3 and capable of clamping the workpiece and driving the workpiece to rotate around its central axis ;

[0027] And, a mill frame feeding part located on the installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com