Chip absorbing and cooling connecting piece used for boring end effector

An end-effector and connector technology, which is used in boring machine/drilling machine components, maintenance and safety accessories, drilling/drilling equipment, etc. Harm the operator's health and other problems, and achieve the effect of improving the surface quality of workpiece processing, reducing reuse, and protecting health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the accompanying drawings.

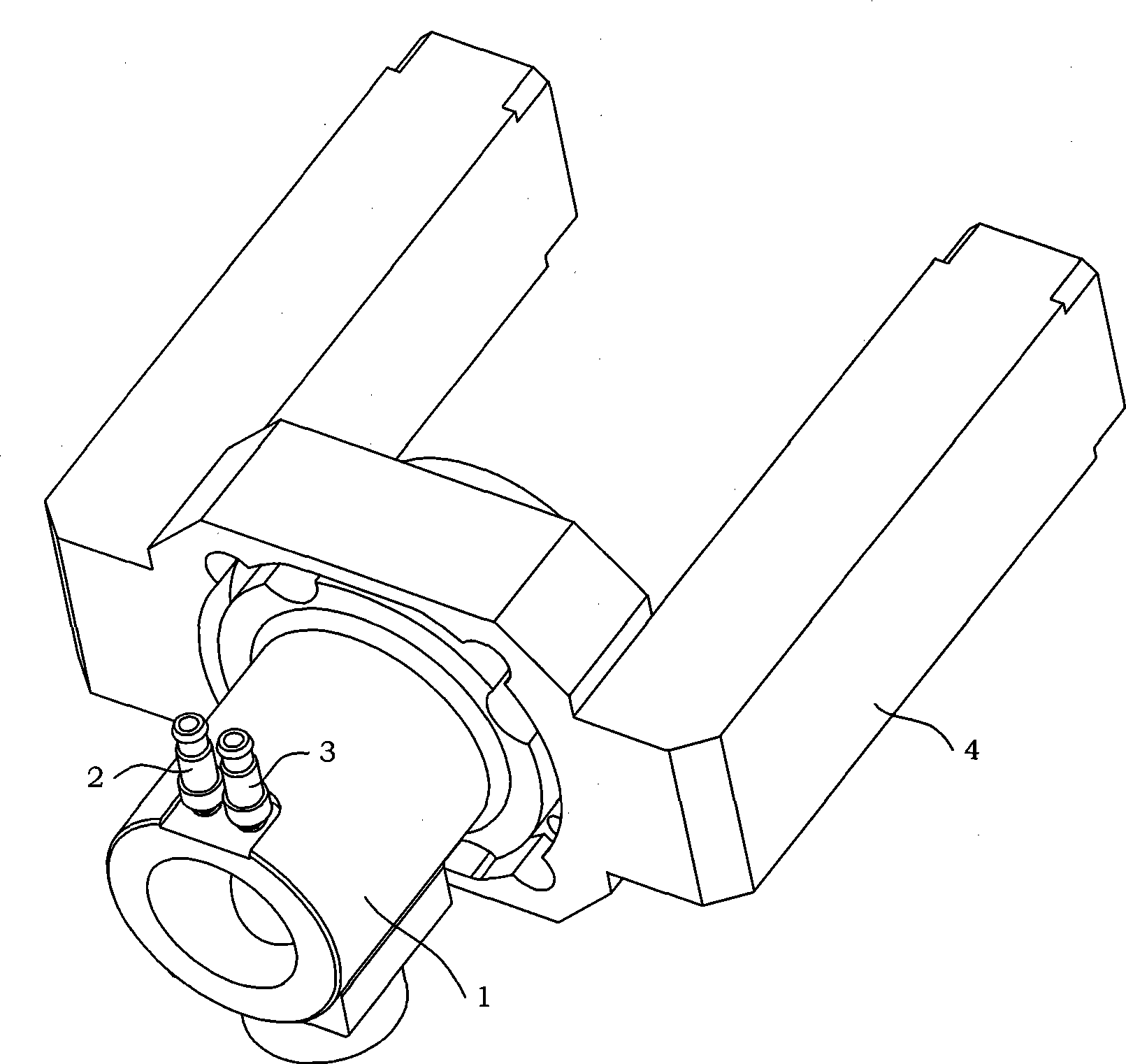

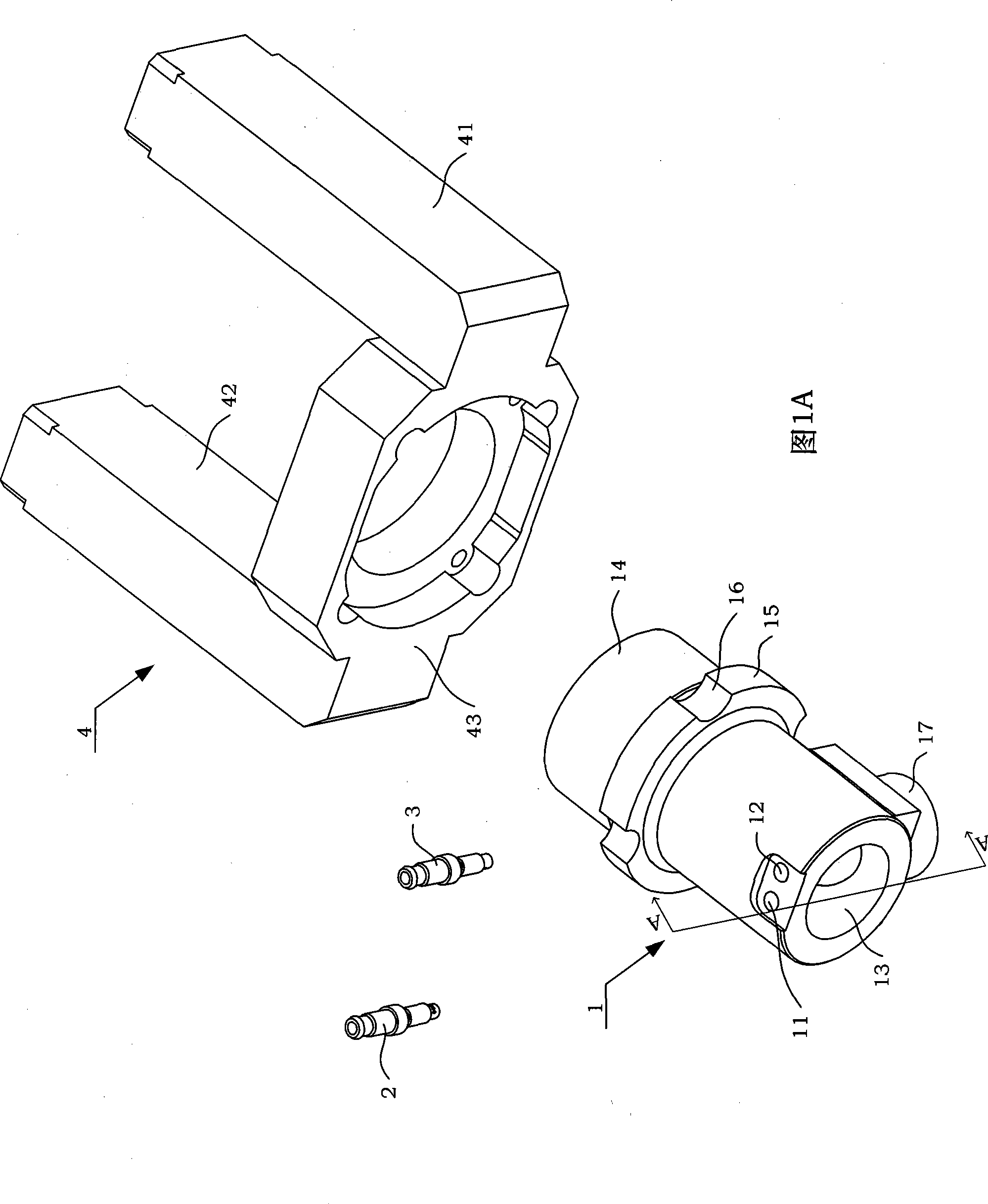

[0027] see figure 1 , figure 1 As shown in A, the present invention is a chip suction and cooling connector for a drilling end effector, which consists of a pressure head shell 1, A nozzle 2, B nozzle 3 and a presser foot 4, and A nozzle 2 and B The structure of the nozzle 3 is the same; the A nozzle 2 and the B nozzle 3 are respectively installed (threaded connection) in the A threaded holes 11 and B threaded holes 12 on the upper part of the front end of the indenter shell 1, and the rear end 14 of the indenter shell 1 is installed in the inside the countersunk hole 44 of the presser foot 4 .

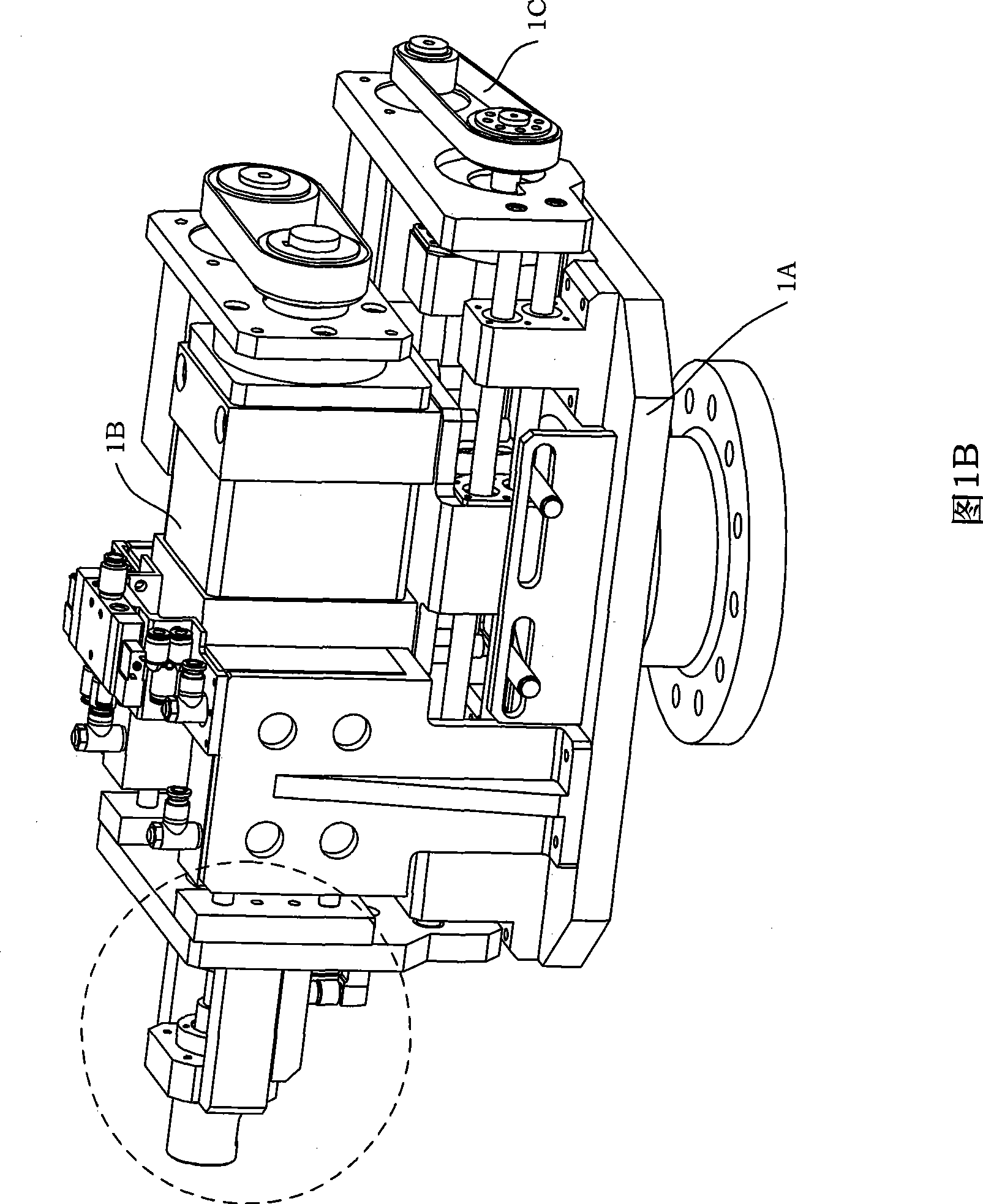

[0028] The novel chip suction and cooling connector designed by the present invention is installed on the front plate of the support unit 1A of the drilling end effector. See figure 1 shown in B. For the structure of the drilling end effector, see the patent applic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com