High-speed rotary ultrasonic torsional processing device

A technology of high-speed rotation and processing equipment, applied in the direction of fluid using vibration, etc., can solve the problems of reducing energy transfer efficiency, inability to realize rotational motion, magnetic eddy current loss, etc., to achieve broadband high-frequency work, miniaturization design, and large Effects of Ultrasonic Energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

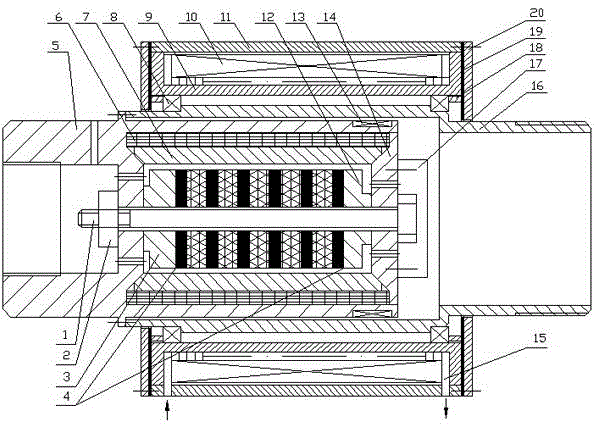

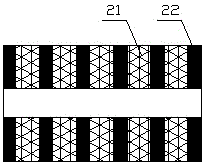

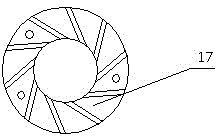

[0028] like figure 1 — Figure 4As shown, a high-speed rotating ultrasonic torsional vibration processing device of the present invention includes a pre-tightening bolt 1, a nut 2, a front radiation block 3, a rare earth rod 4, an output shaft 5, a piezoelectric ceramic 6, a piezoelectric ceramic pressure cylinder 7, Rolling bearing 8, coil frame 9, excitation coil 10, outer sleeve 11, rear radiation pressure block 12, induction coil 13, compression end cover 14, cooling water pipe 15, transmission shaft 16, turbo fan 17, positioning sleeve 18, seal The washer 19, the yoke end cover 20, the output shaft 5 and the transmission shaft 16 are all stepped shafts with stepped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com