End part cutter for valve rod

A valve stem and cutting machine technology, used in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as poor machining accuracy, and achieve the effects of low surface roughness, small residual stress, and not easy to burn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

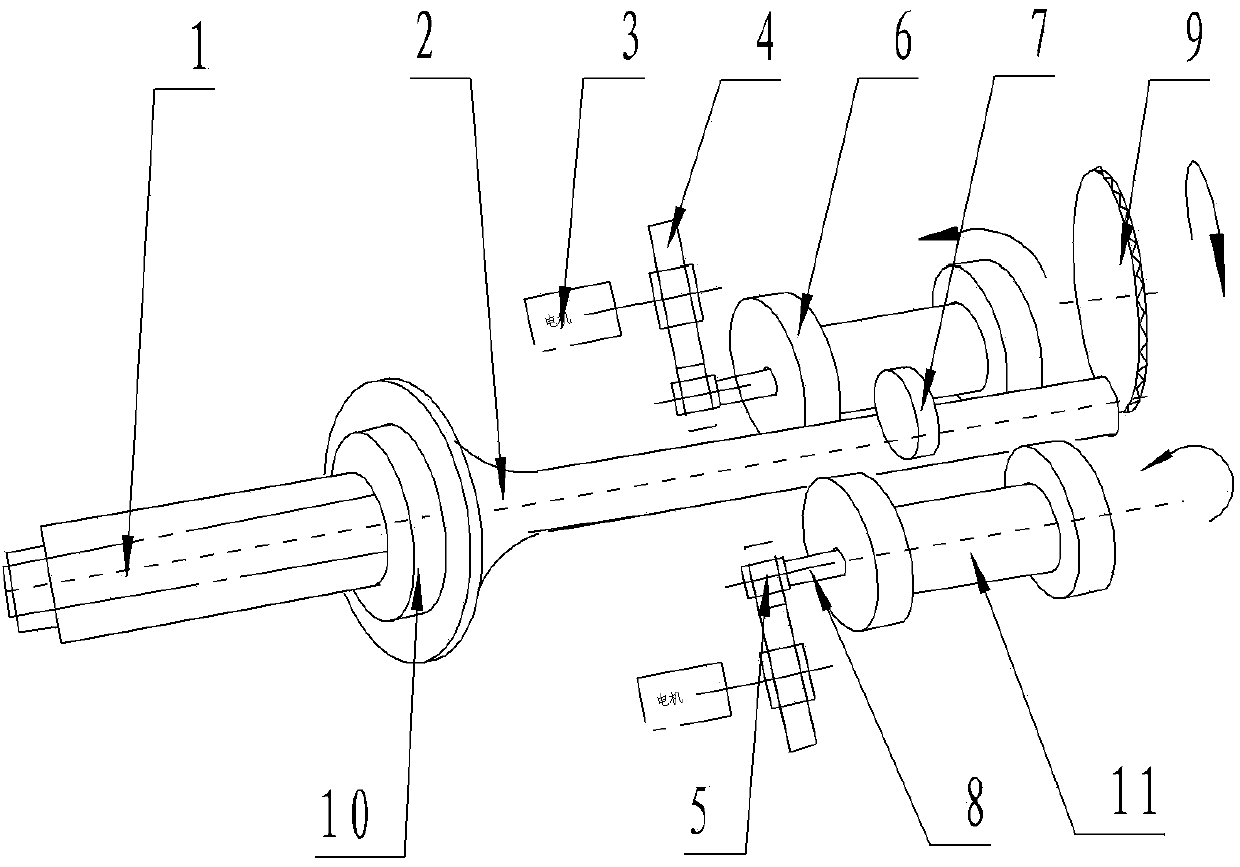

[0022] Embodiment 1, a valve stem end cutting machine is characterized in that it includes a valve rotation drive device, a valve positioning device and a valve stem end cutting device,

[0023] The valve rotation driving device is composed of two parallel and synchronously rotating rollers 6 with rotation driving devices located below the valve stem and a pressure roller 7 above the valve stem.

[0024] The valve positioning device is composed of a rotatable positioning rod 1 located outside the valve disc and a disc-shaped movable positioning head 10 installed at the front end of the positioning rod.

[0025] The valve stem end cutting device is a high-speed rotating CBN grinding wheel 9 with a feed system.

Embodiment 2

[0026] Embodiment 2, a valve stem end cutting machine is characterized in that it includes a valve rotation drive device, a valve positioning device and a valve stem end cutting device,

[0027] The valve rotation driving device is composed of two parallel and synchronously rotating rollers 6 with rotation driving devices located below the valve stem and a pressure roller 7 above the valve stem.

[0028] The valve positioning device is composed of a rotatable positioning rod 1 located outside the valve disc and a disc-shaped movable positioning head 10 installed at the front end of the positioning rod.

[0029] The valve stem end cutting device is a high-speed rotating CBN grinding wheel 9 with a feed system.

[0030] The structure of the roller is that two circular wheels of equal diameter are installed at both ends of the roller mandrel 11 .

[0031] The rotary driving device of the valve rotary driving device is composed of a motor 3 fixed on the equipment base, a motor ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com