Modularization type material addition and reduction composite repairing method for defective region of component surface

A composite repair and modular technology, applied in the field of mechanical processing, can solve problems such as preprocessing of the area to be repaired, etc., and achieve the effects of improving repair efficiency and repair quality, convenient and fast path planning, and simple shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

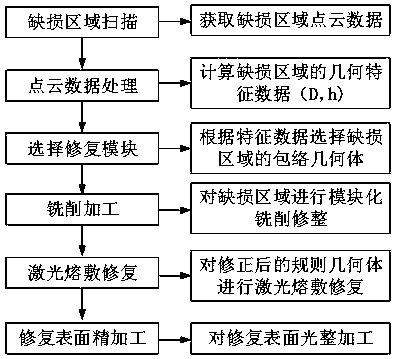

[0030] A method for repairing surface defects of parts by modularization, adding and subtracting materials, comprising the following steps:

[0031] (1) Place the part to be repaired on the workbench so that the area I to be repaired faces upward;

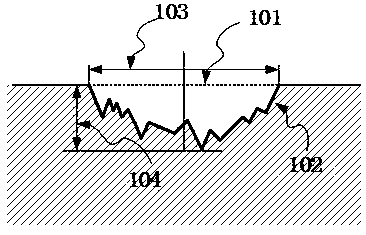

[0032] (2) Perform laser three-dimensional scanning of the area I to be repaired and its surroundings to obtain point cloud data of the defect and surrounding areas, and scan coordinate reference points at the same time;

[0033] (3) Calculate and process the point cloud data of the defect part and the surrounding area obtained in step (2) to obtain the characteristic parameters of the defect part;

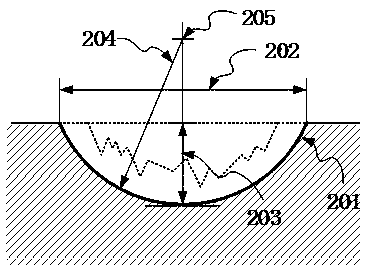

[0034] (4) Estimate the normal vector of the original surface of the defect area according to the point cloud data of the defect part and the surrounding area obtained in step (2); select a regular envelope geometry module suitable for the defect area according to the characteristic parameters of step (3) , the envelope geometry modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com