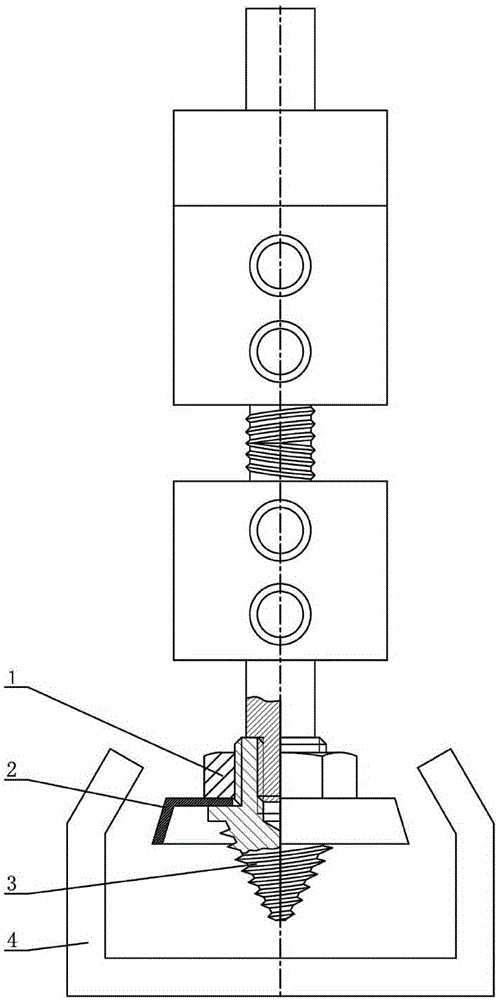

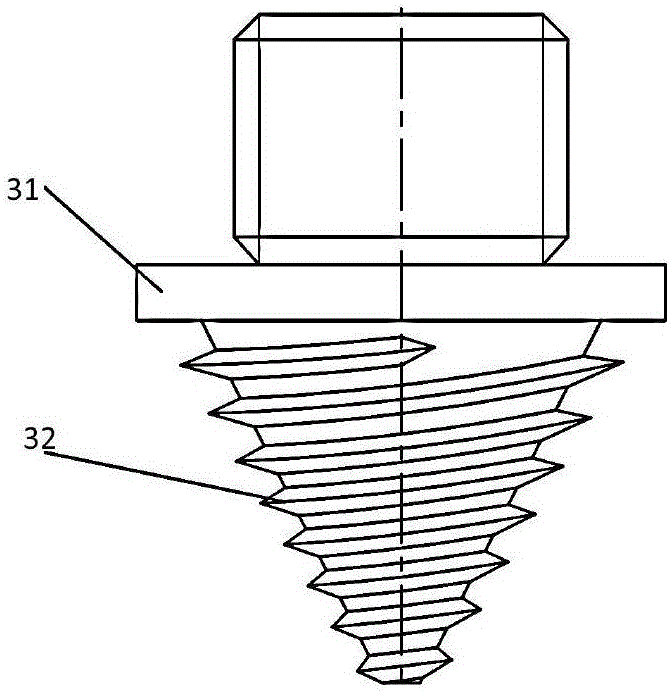

Double-shaft-shoulder stir friction head water-cooling cooling device and stir friction welding device and method

A friction stir, water-cooled heat dissipation technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., to achieve the effect of improving welding quality, simple heat dissipation structure, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

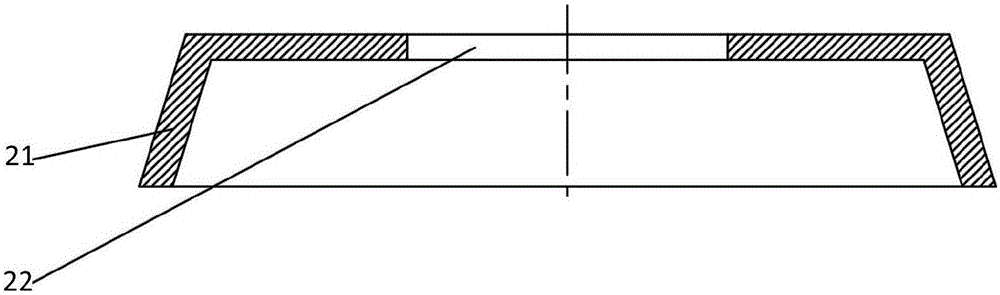

[0023] In order to solve the above-mentioned problems existing in the prior art, the applicant conducted in-depth research, and the applicant found that: in actual engineering operation, the increase of the rotating speed and forward speed will cause excessive heat production, resulting in uneven heat production at the upper and lower shoulders , The grain size on the upper and lower surfaces of the weld is different, and the fluidity of the structure is poor. This is the cause of defects such as flashing, holes, tunnels, etc. The temperature measurement of the friction stir head with two shoulders during welding shows that the temperature of the lower shoulder is significantly higher than that of the upper shoulder. The study found that: the upper shoulder is connected to the head part of the welding machine, and the heat is lost quickly; the lower shoulder is small in size and has a small heat dissipation area, which is easy to cause overheating on the lower surface of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com