Flat gasket automatic assembly machine

A fully automatic and assembly machine technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult installation accuracy, low installation efficiency, easy to be blown away by the wind, etc., to achieve fully automated production, production Efficiency improvement and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

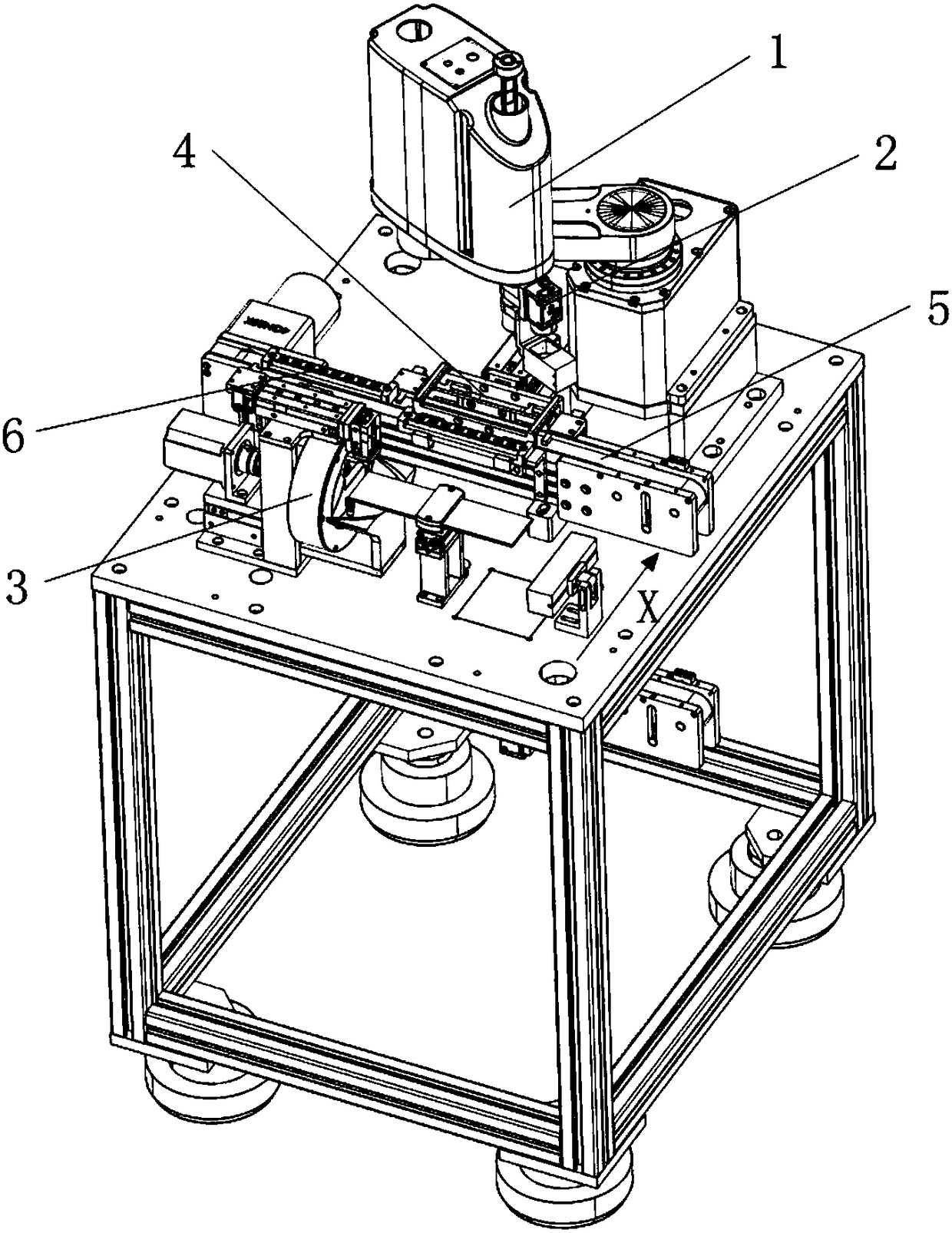

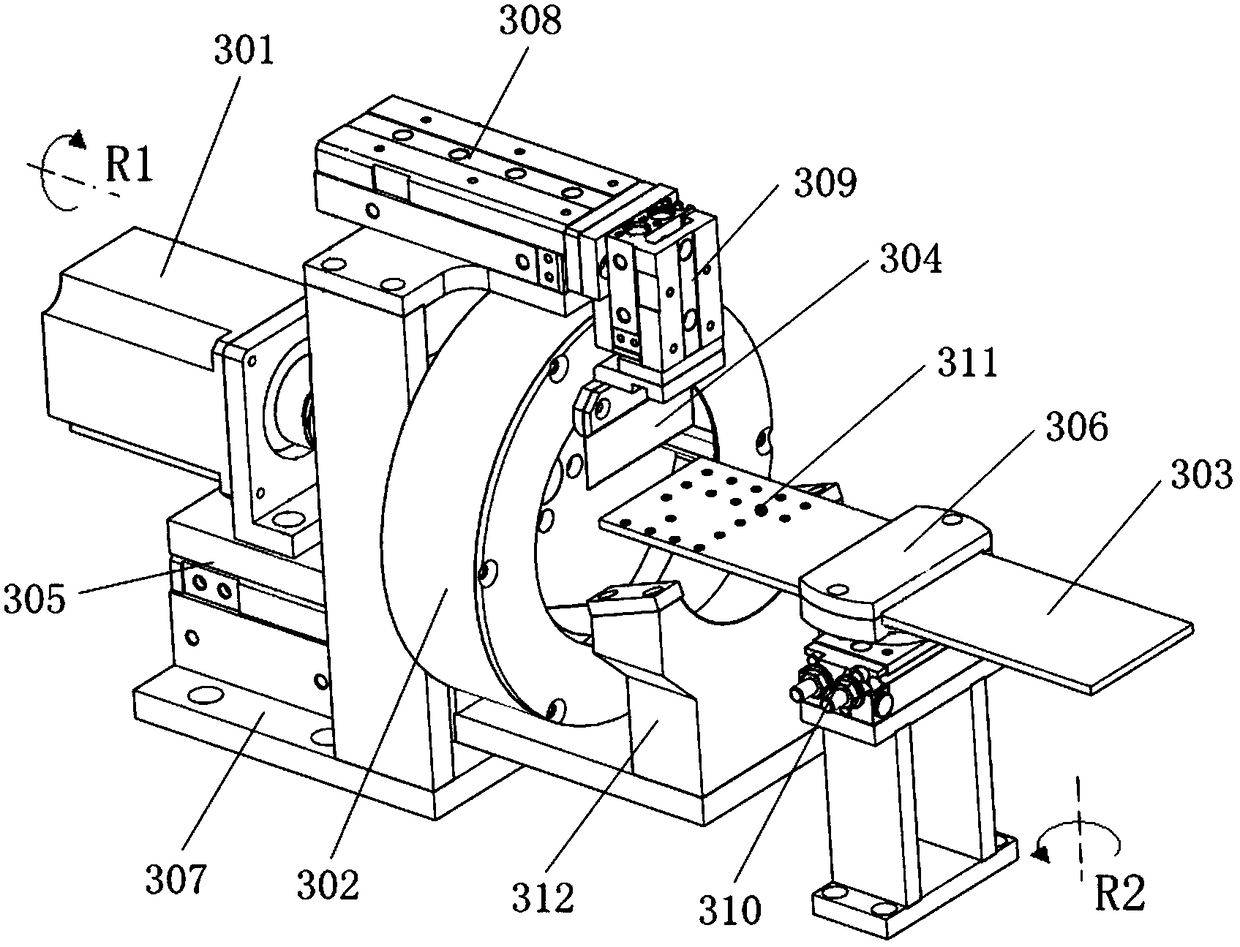

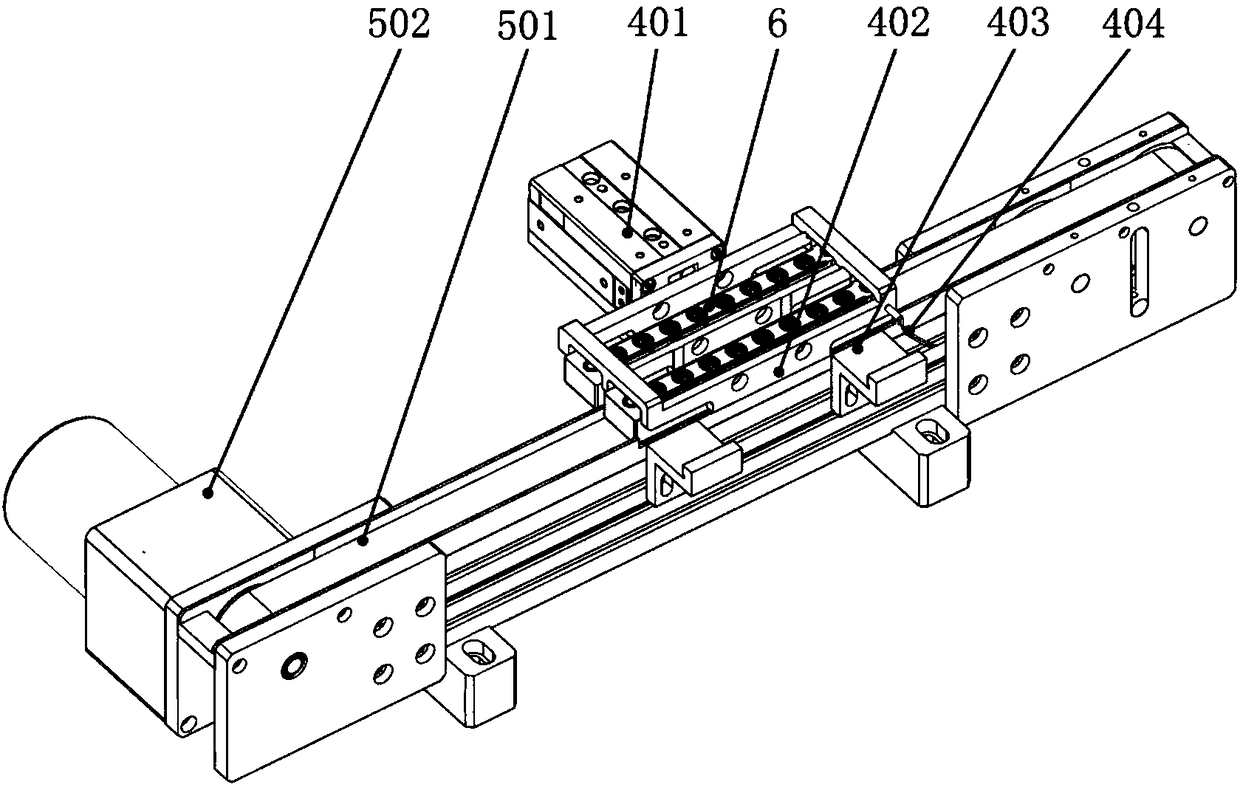

[0021] As shown in the figure, the flat gasket automatic assembly machine in the present invention includes a manipulator 1, a CCD 2, a discharge device 3, an intercepting device 4, a conveying device 5 and a control system, and the intercepting device 4 is covered above the conveying device 5 , the discharge device 3 is arranged on one side of the conveying device 5, the manipulator 1 is arranged above the one side of the conveying device 5, and the CCD2 has two groups, which are respectively arranged on the manipulator 1 and the discharge device 3. The automatic assembly machine lays flat gaskets through the discharge device 3, and the turnover bar 6 equipped with workpieces runs on the conveying device 5. The gasket is fixed on the workpiece, the overall process is simple, the degree of automation is high, and the production efficiency i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com