Device for monitoring abnormal working state of numerical control milling cutter and monitoring method of device

A technology of working status and monitoring devices, which is applied in the direction of manufacturing tools, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of online and real-time monitoring and control of tool wear and damage, and achieve manpower saving, accurate measurement accuracy, Avoid the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

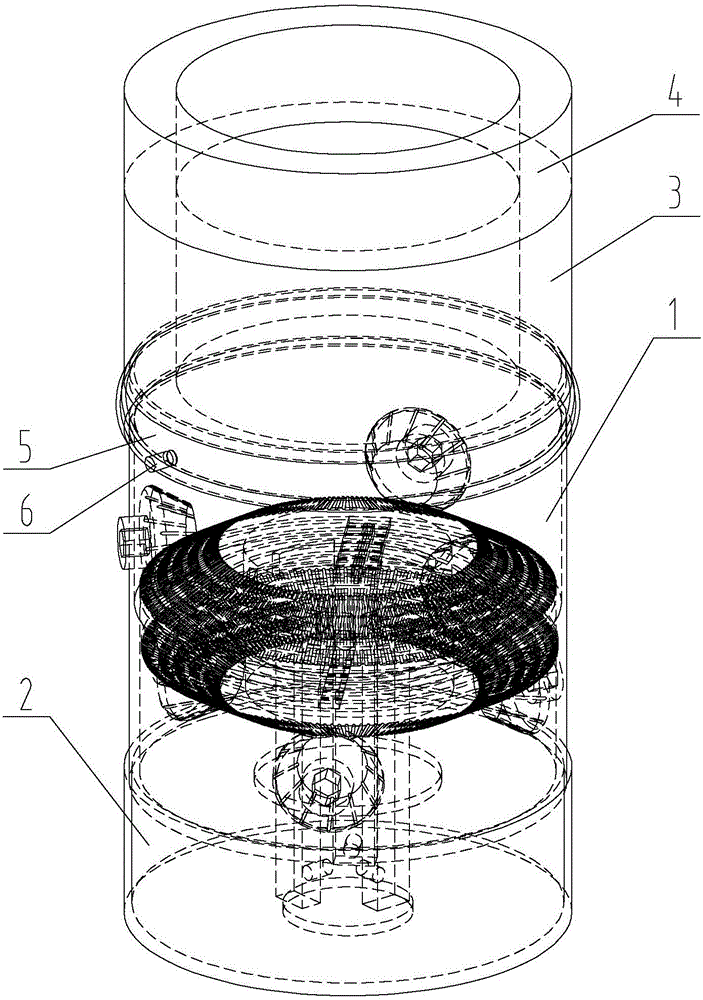

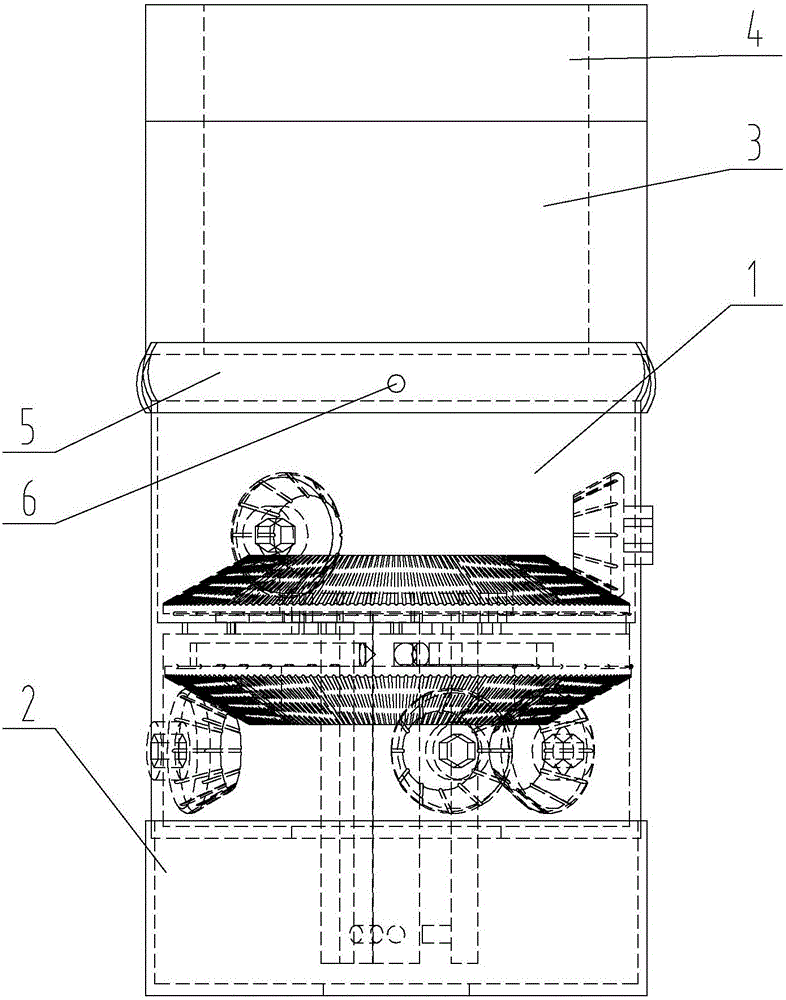

[0037] Specific implementation mode one: combine Figure 1 to Figure 15 Describe this embodiment, the monitoring device of a kind of numerical control milling tool abnormal working state described in this embodiment comprises measuring head 1, observation cover 2, collecting and transmitting mechanism 3, permanent magnetic sucker 4 and control panel, and observing cover 2 is arranged on the measuring head 1, the upper end of the measuring head 1 is provided with a permanent magnetic chuck 4, a collection and launching mechanism 3 is arranged between the measuring head 1 and the permanent magnetic chuck 4, and a positioning through hole 2-1 is arranged on the lower end surface of the observation cover 2, and the measurement The head 1 includes an outer casing 1-1, a positioning mechanism and an adjustment mechanism, the positioning mechanism and the adjustment mechanism are respectively arranged inside the outer casing 1-1, and the adjustment mechanism is provided with an eddy c...

specific Embodiment approach 2

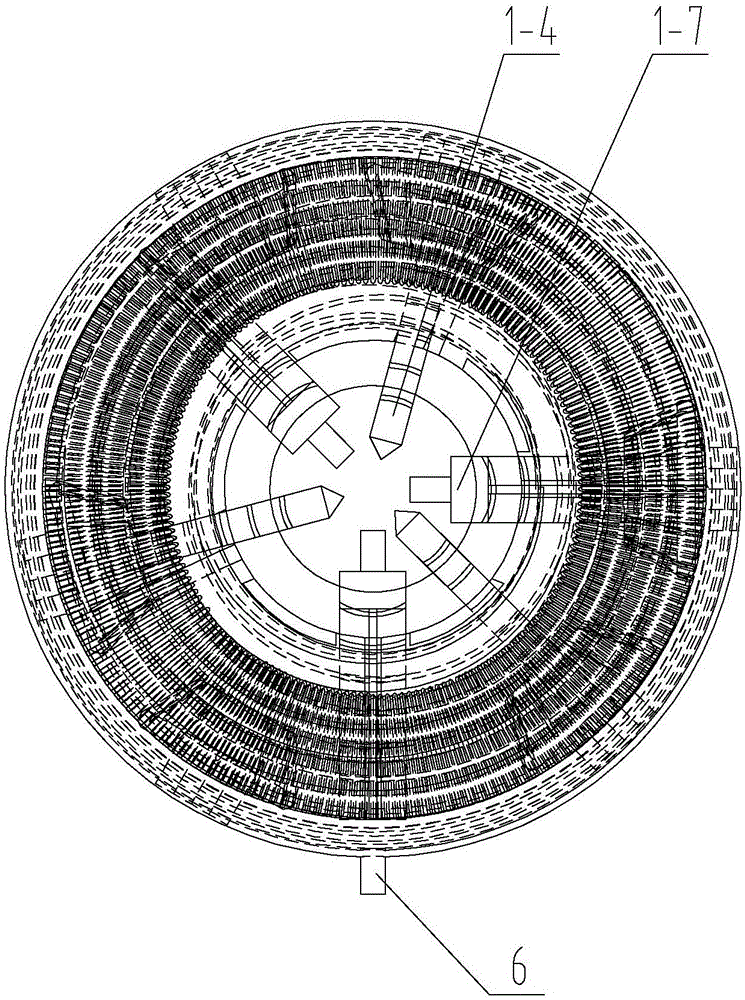

[0038] Specific implementation mode two: combination Figure 1 to Figure 14 To illustrate this embodiment, a partition 1-1-1 is provided inside the outer casing 1-1 of this embodiment, and three first limiting grooves 1-1-1 are respectively provided on the partition 1-1-1 along the radial direction. 2 and three second limiting grooves 1-1-3, the middle part of the partition plate 1-1-1 is provided with a middle through hole 1-1-4, and the positioning mechanism includes a positioning large bevel gear 1-2, a group of positioning small Bevel gear 1-3 and three positioning columns 1-4, the adjustment mechanism includes adjusting large bevel gear 1-5, a set of adjusting small bevel gear 1-6 and three claws 1-7, positioning large bevel gear 1-2 The large bevel gear 1-5 is symmetrically arranged on both ends of the partition 1-1-1, and the end faces of the large bevel gear 1-2 and the large bevel gear 1-5 are set inward respectively, and the large bevel gear 1-5 is positioned inward....

specific Embodiment approach 3

[0039] Specific implementation mode three: combination Figure 1 to Figure 4 Describe this embodiment, the monitoring device of a kind of CNC milling tool abnormal working state described in this embodiment also includes joint bearing 5, and joint bearing 5 is arranged between collecting and transmitting mechanism 3 and measuring head 1, and the upper end of measuring head 1 passes through lock Tightening screw 6 is connected with joint bearing 5. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

[0040] In this embodiment, the measuring head 1 is connected with the collection and launching mechanism 3 through the joint bearing 5 to prevent the unevenness of the upper surface adsorbed by the permanent magnetic chuck 4 from affecting the positioning of the measuring head 1, thereby ensuring the measurement accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com