Polishing and impurity removal mechanism for BGA solder balls

A solder ball and polishing mechanism technology, which is applied in the direction of grinding racks, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve problems such as mist and wrinkles on the surface of solder balls, achieve removal of debris and impurities, and improve Effect of Surface Roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

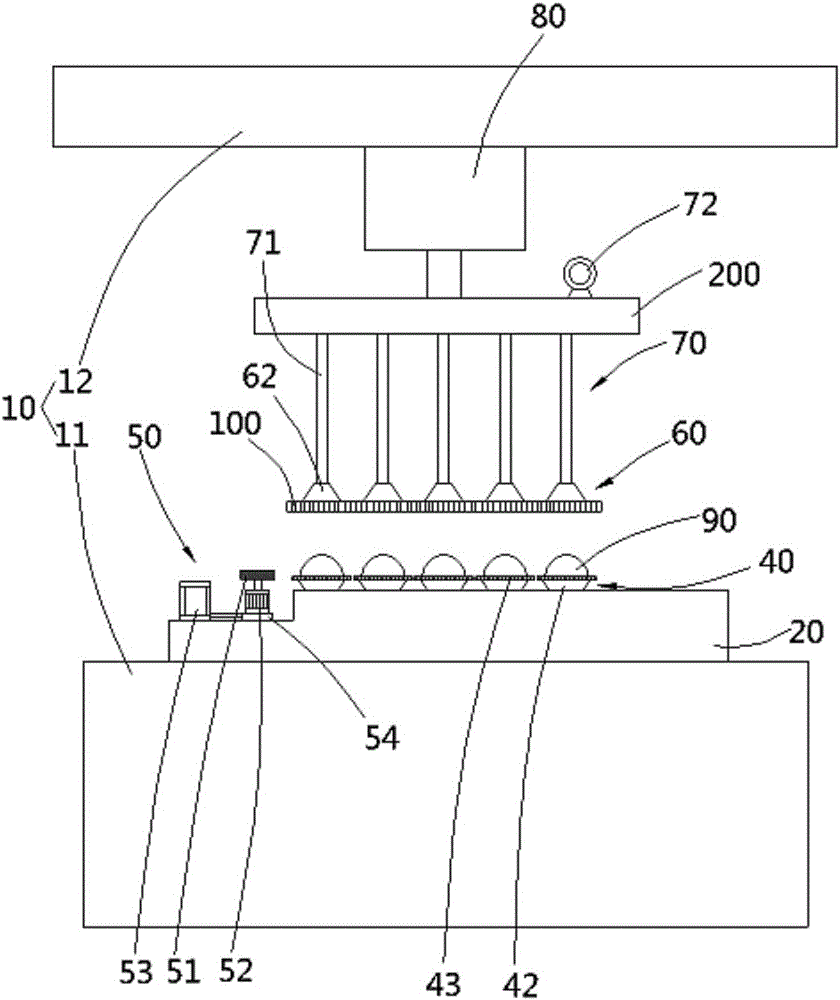

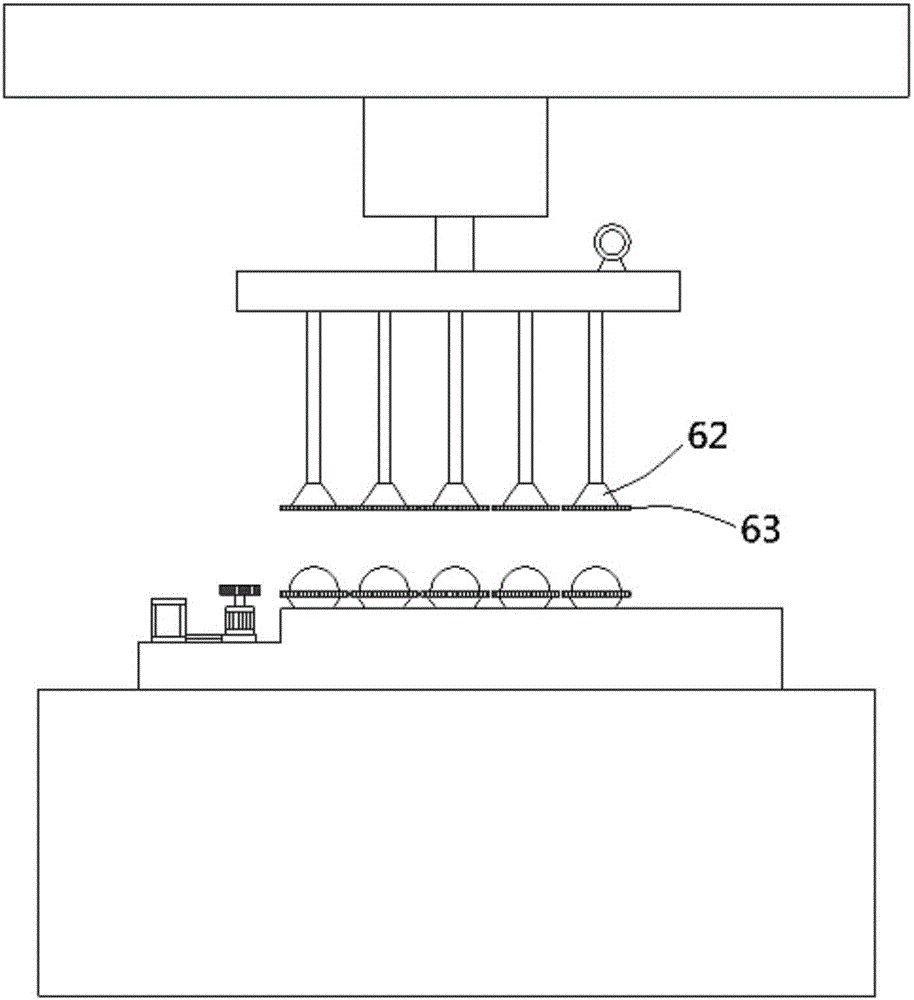

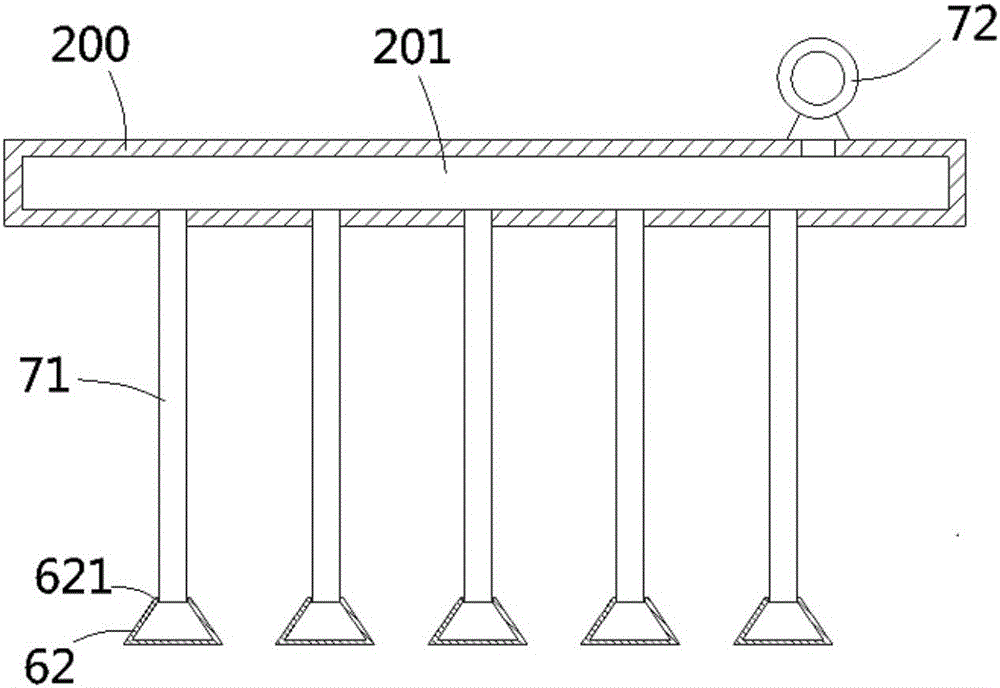

[0024] see figure 1 A mechanism for grinding and removing impurities of BGA solder balls according to the present invention includes a frame 10, the frame includes a base 11 and a beam 12 above the base, and a carrier plate is movable on the base 11 20. A pair of parallel linear guide rails 30 are formed on the upper end surface of the base 11, the carrier plate 20 is arranged on the linear guide rails 30, and the linear guide rails are elongated guide grooves 30 formed on the upper end surface of the base 11, A pair of guide blocks 21 cooperating with the guide groove 30 are formed on the bottom surface of the carrier plate 20. The guide block 21 is inserted in the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com