Transporting and storing method for rotary cutter

A preservation method and technology of rotating knives, applied in the field of protective sleeves, can solve the problems of easy collision, damage, and easy falling off of finished products, and achieve the effects of convenient packaging, reducing external force, and safe storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

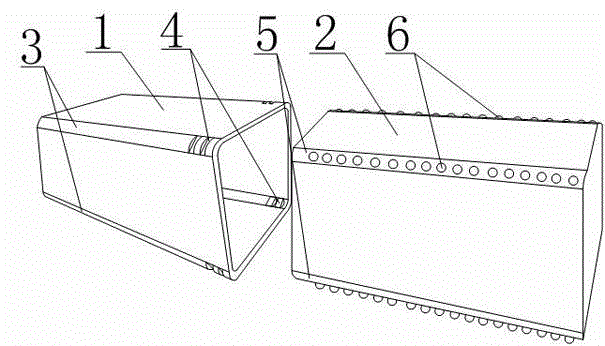

[0017] Such as figure 1 As shown, a method for transporting and storing rotary cutters of the present invention includes a cuboid overall and an external socket 1 with an open end, and an internal socket 2 that matches the external socket 1. Both the external socket 1 and the internal socket 2 include four Two side surfaces and a bottom surface, a connection surface 3 is provided between any two adjacent sides of the outer socket 1, an angle of 45° is formed between the connection surface 3 and the two sides, and the connection surface 3 near the open end is inwardly recessed, Two projections 4 are formed on the connection surface 3 of the inner cavity of the outer sleeve 1, and an insertion surface 5 is arranged between any two adjacent side surfaces of the inner sleeve 2, and an insertion surface 5 is arranged between the two side surfaces. Forming an included angle of 45°, the insertion surface 5 protrudes outward to form a plurality of blocks 6 , and the plurality of block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com