A polygeneration method for joint conversion of multiple coal types

A poly-generation, multi-coal technology, applied in chemical instruments and methods, joint combustion mitigation, preparation of liquid hydrocarbon mixtures, etc. Responding to market demand and enriching products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, adopt the polygeneration method of multi-coal joint transformation of the present invention to produce multiple products

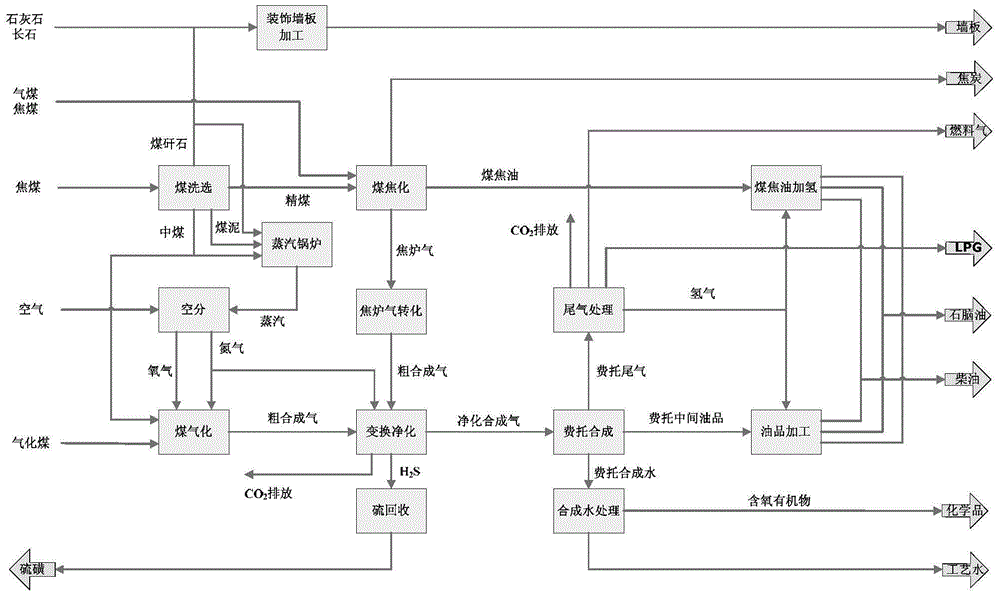

[0044] according to figure 1 The process shown is for joint conversion of various coals, and the specific steps are as follows:

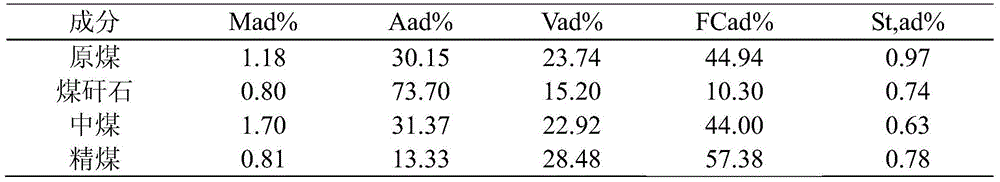

[0045] (1) Coal gangue (1,545,600 tons / year), coal slime (140,700 tons / year), medium coal (2,132,200 tons / year) and refined Coal (3.1815 million tons / year), coal quality analysis before and after coal washing is shown in Table 1. Part of the washed coal gangue (1.4656 million tons / year) is processed together with limestone (209,400 tons / year) and feldspar (104,700 tons / year) to produce exterior wall decorative panels (1271m 2 / h).

[0046] Table 1. Analysis of coal quality before and after coal washing

[0047]

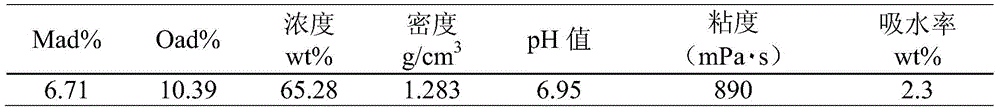

[0048] (2) Raw material air obtains oxygen and nitrogen through air separation under the effect of steam, and wherein steam comes from the coal gangue (80,000 tons / year) of washing of another...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com