Method for making baijiu through nine-crop nine-step making technology

A process and liquor technology, applied in the field of brewing technology for brewing Jiuliang-flavor liquor, can solve problems such as incompleteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

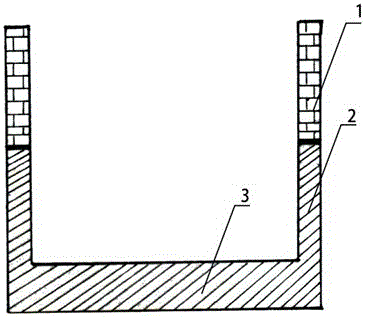

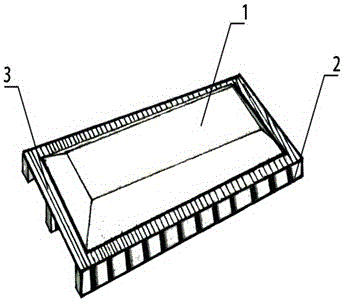

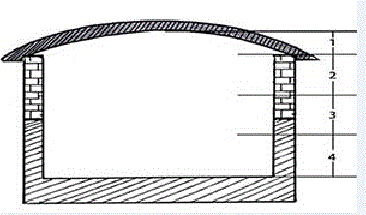

Image

Examples

Embodiment 1

[0130] Example 1 Time September 8, 2014 No. 3, Row 2, Workshop 2

[0131] The first round: Feed 1600kg of grain, crush sorghum, wheat, rice, glutinous rice, and black rice into 3 pieces, crush corn and mung beans into rice size, sand rice, tartary buckwheat without powder, mix and mix evenly, and feed at 30°C Measure 20% warm water to moisten the grain for 2 hours, then mix it evenly with 45% strong aroma, 15% light fragrance, 20% sauce aroma, and 20% sesame aroma. 8 hours, covered with 6% rice husk. After a series of processes such as moistening→distilling→cooling→adding koji→accumulating→putting into cellars→sealing→fermenting→opening cellars, the first round of base wine is produced, with outstanding grain aroma, delicate body and typical style. (See attached table for physical and chemical analysis) The yield of alcohol is 40.8%.

[0132] The stacking temperature in the pit is 28°C, the stacking temperature is raised to 43°C, the pit entry temperature is 29°C, the pit en...

Embodiment 2

[0133] Example 2 Time October 11, 2014 No. 4, Row 2, Workshop 2

[0134] The second round: Feed 1400kg of grain, crush sorghum, wheat, rice, glutinous rice, and black rice into 3 pieces, crush corn and mung beans into rice size, sandy rice, and tartary buckwheat are not powdered, mix them evenly, and use 30°C with a total input of 18 % warm water to moisten the grain for 2 hours, and then use the fermented grains fermented in the first round to moisten the grains for 9 hours according to the grain-to-grain ratio of 1:3.5, and cover with 8% rice husk. After a series of processes such as moistening→distilling→cooling→adding koji→accumulating→putting into cellars→sealing→fermenting→opening cellars, the second round of base wine is produced. (See attached table for physical and chemical analysis) Liquor yield is 43.2%.

[0135] The stacking temperature in the pit is 28°C, the stacking temperature is raised to 43°C, the pit entry temperature is 29°C, the pit entry starch is 24.5%,...

Embodiment 3

[0136] Example 3 Time November 13, 2014 No. 5, Row 2, No. 2 Workshop

[0137] The third round: Feed 1200kg of grain, crush sorghum, wheat, rice, glutinous rice, and black rice into 4 petals, crush corn and mung beans into rice size, sandy rice, tartary buckwheat are not powdered, mix them evenly, and use 30°C with a total feeding amount of 18 % warm water to moisten the grain for 2 hours, then use the fermented fermented grains fermented in the second round to moisten the grains for 10 hours according to the grain-to-grain ferment ratio of 1:3.5, and cover with 10% rice husk. After a series of processes such as moistening→distilling→cooling→adding koji→accumulating→putting into cellars→sealing→fermenting→opening cellars, the third round of base wine is produced. (See attached table for physical and chemical analysis) The yield of alcohol is 44.2%.

[0138] The stacking temperature in the pit is 30°C, the stacking temperature is raised to 43°C, the pit entry temperature is 30°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com