Accelerated flow energy dissipation and energy feedback device of iron concentrate slurry pipeline and control method of device

An energy feedback, iron concentrate technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of wasted energy, energy consumption is not well recovered, uneconomical, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

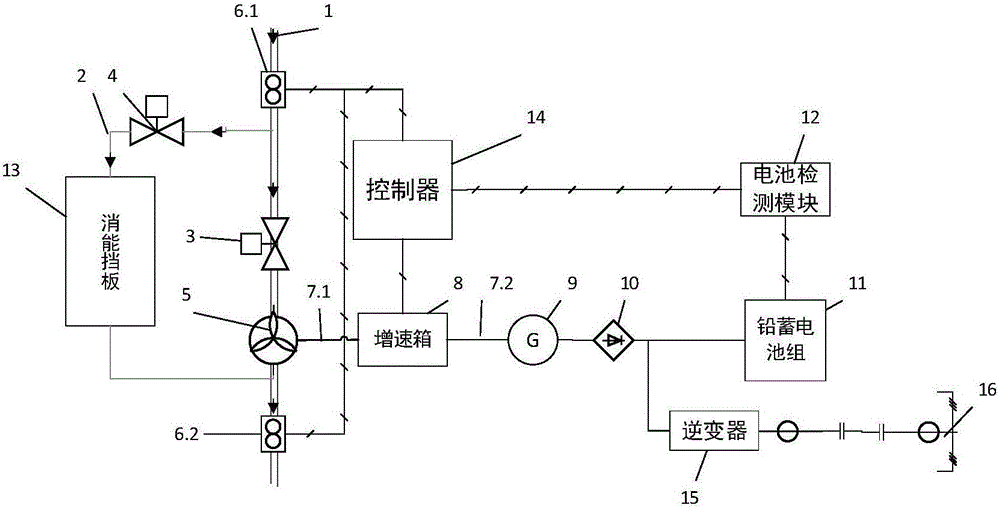

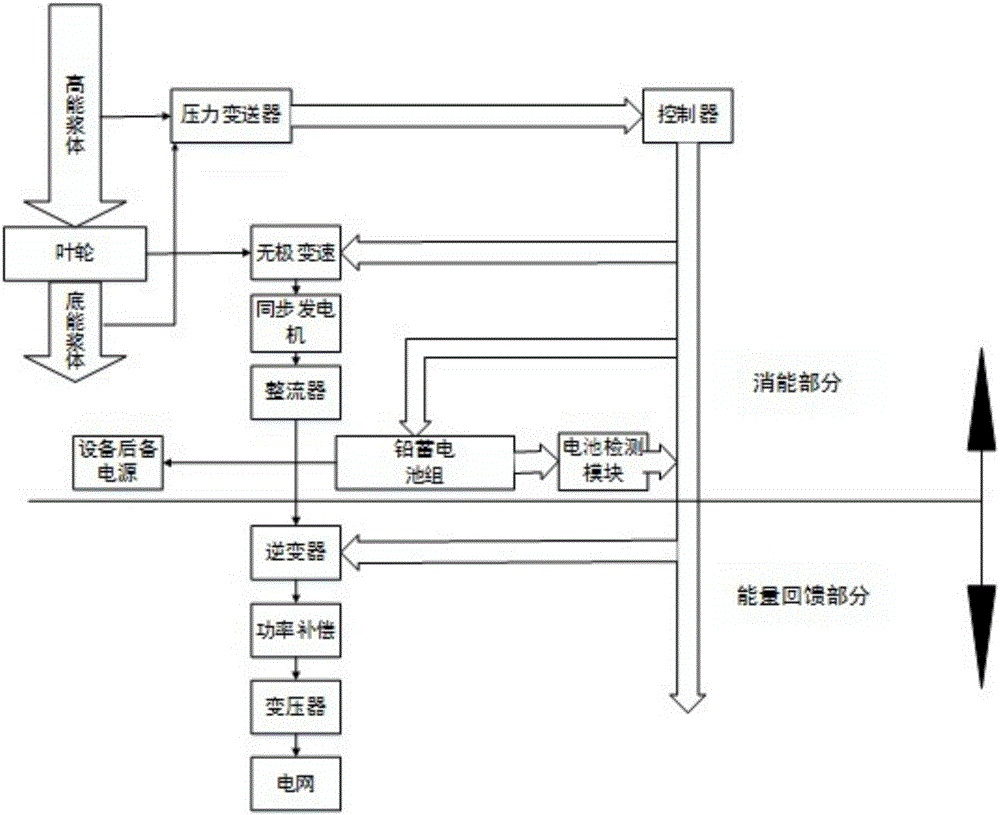

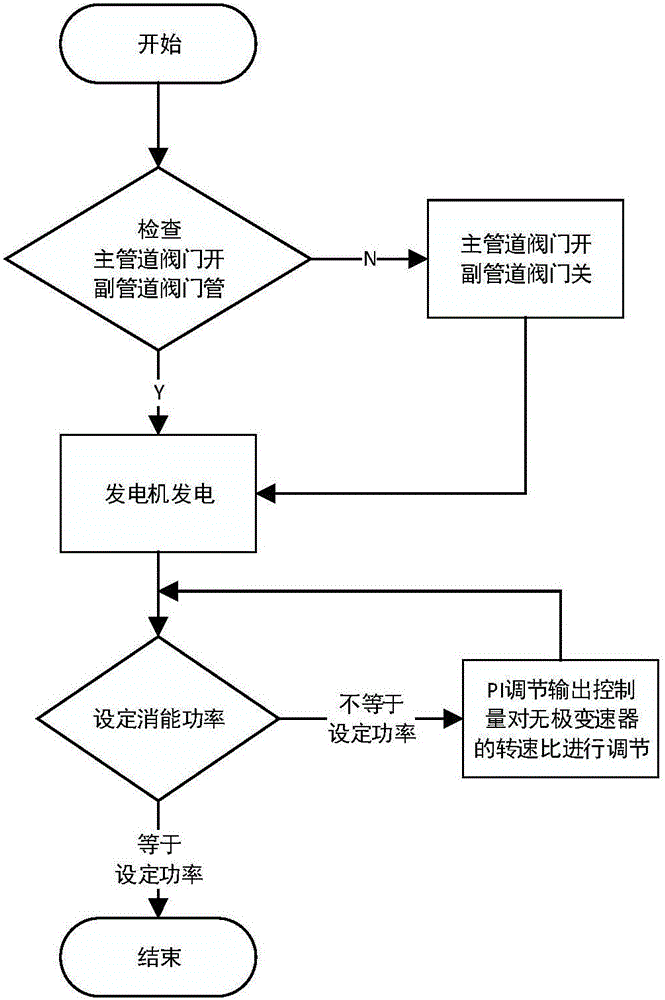

[0034] Embodiment 1: as Figure 1-5 As shown, an iron concentrate slurry pipeline acceleration flow energy dissipation and energy feedback device includes main pipeline 1, auxiliary pipeline 2, electric knife switch valve I3, electric knife switch valve II4, centrifugal pump 5, and pressure transmitter I6. 1. Pressure transmitter Ⅱ6.2, coupling Ⅰ7.1, coupling Ⅱ7.2, gearbox 8, synchronous generator 9, rectifier group 10, battery group 11, battery detection module 12, energy dissipation block Board 13, controller 14, inverter 15, enterprise internal grid 16;

[0035] The auxiliary pipeline 2 is installed next to the main pipeline 1, and the energy dissipation baffle 13 is installed on the auxiliary pipeline 2. The control input line of the energy dissipation baffle 13 is connected to the controller 14, the electric knife puller valve I3, the electric knife puller valve II4 The opening and closing control lines of the pressure transmitter are connected to the controller 14, the ...

Embodiment 2

[0042] Embodiment 2: as Figure 1-5 As shown, an iron concentrate slurry pipeline acceleration flow energy dissipation and energy feedback device includes main pipeline 1, auxiliary pipeline 2, electric knife switch valve I3, electric knife switch valve II4, centrifugal pump 5, and pressure transmitter I6. 1. Pressure transmitter Ⅱ6.2, coupling Ⅰ7.1, coupling Ⅱ7.2, gearbox 8, synchronous generator 9, rectifier group 10, battery group 11, battery detection module 12, energy dissipation block Board 13, controller 14, inverter 15, enterprise internal grid 16;

[0043] The auxiliary pipeline 2 is installed next to the main pipeline 1, and the energy dissipation baffle 13 is installed on the auxiliary pipeline 2. The control input line of the energy dissipation baffle 13 is connected to the controller 14, the electric knife puller valve I3, the electric knife puller valve II4 The opening and closing control lines of the pressure transmitter are connected to the controller 14, the ...

Embodiment 3

[0049] Embodiment 3: as Figure 1-5 As shown, according to the actual transportation situation of the iron concentrate slurry pipeline (diameter 100mm) operated by a certain company, every 100m of pressure head can generate 23KW energy and recover electric energy of 23ηKW (efficiency factor η). The system has 500m of excess slurry pressure head, can generate 115KW of energy, and generates power of 115ηKW. Centrifugal pump 5 selects 80DFZ-520A type slurry pump (efficiency 70%) produced by Shijiazhuang Dongfanghong Industrial Pump Factory. The controller 14 adopts Micrologic1400PLC and 1762-IQ16, 1762-IF2OF2 expansion I / O modules of American Rockwell Company. Electric knife switch valve I3 and electric knife switch valve II4 can choose DZW10 series knife switch valve manufactured by Yangzhou Xinneng Electric Power Equipment Co., Ltd. The speed-up box (8) can be selected from the planetary speed-up box produced by Shanghai Jiyou Automation Technology Co., Ltd., in continuous op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com