Waste treatment comprehensive utilization system and method for wallpaper processing

A waste and wallpaper technology, which is applied in the field of comprehensive utilization system of waste treatment for wallpaper processing, can solve the problems of inability to deal with organic waste gas, achieve the effects of reducing burning loss, avoiding burning loss, and improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

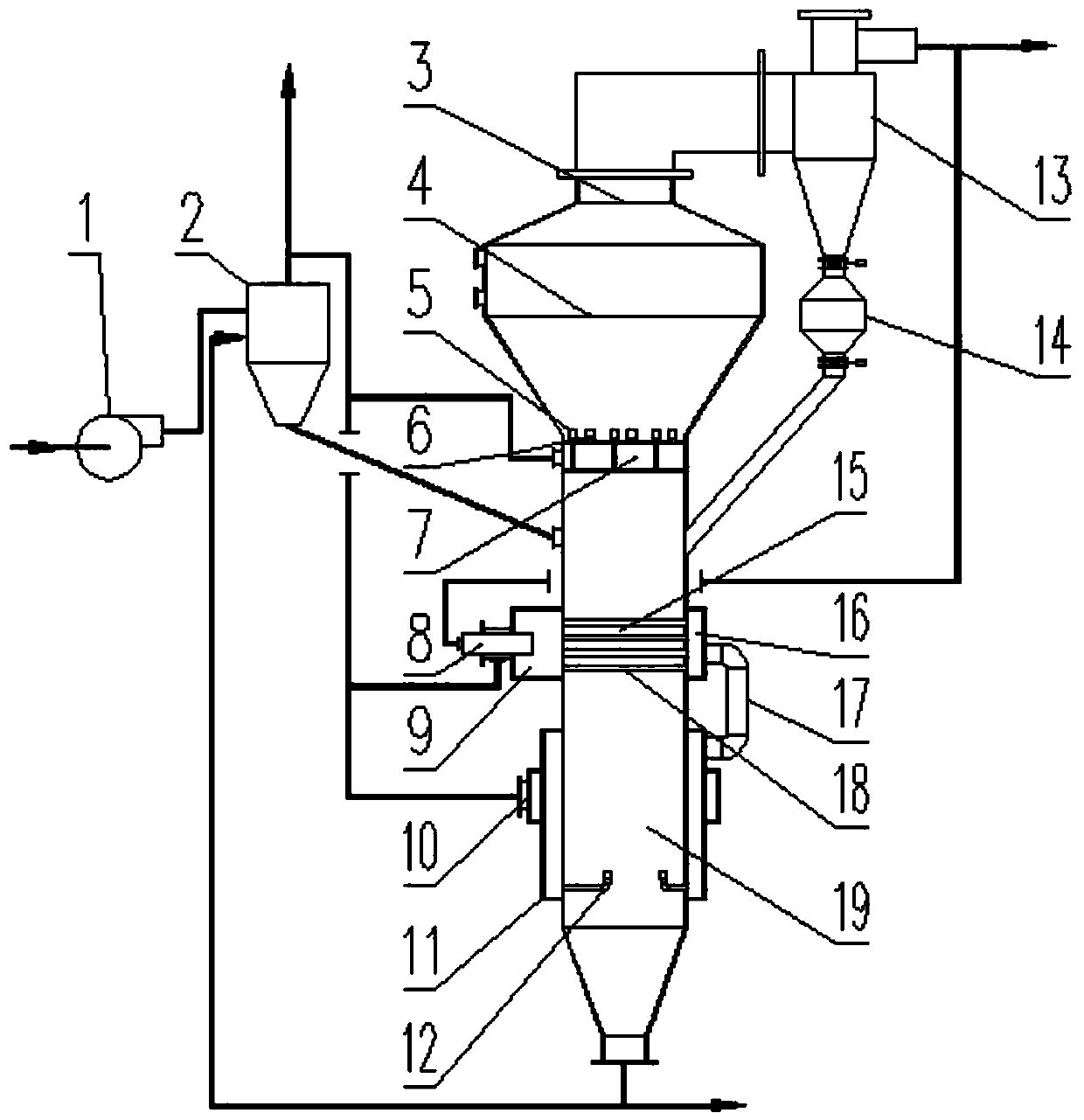

[0047] 1) Finished activated carbon is placed in the filter 2 as an adsorbent, and the suction fan 1 extracts air containing high-concentration organic waste gas from the hot air circulation system of the wallpaper processing and coating machine, and the air containing high-concentration organic waste gas is filtered and adsorbed by filter 2, Most of the organic waste gas is adsorbed in the finished activated carbon, and the filtered air containing trace organic matter is sent to the air inlet of the air chamber 7, the air inlet of the burner 8 in the combustion chamber, and the air inlet of the air distribution ring 10;

[0048] 2) The bed material and waste wood are fed into the crushing pyrolysis chamber 4 through the bed material feeding pipe and the waste wood feeding pipe respectively, the waste wood material is fed continuously, and the filtered air passes through the air chamber 7 and the second air cap 6 The high-temperature flue gas containing combustible gas is spray...

Embodiment 2

[0053] 1) Finished activated carbon is placed in the filter 2 as an adsorbent, and the suction fan 1 extracts air containing high-concentration organic waste gas from the hot air circulation system of the wallpaper processing and coating machine, and the air containing high-concentration organic waste gas is filtered and adsorbed by filter 2, Most of the organic waste gas is adsorbed in the finished activated carbon, and the filtered air containing trace organic matter is sent to the air inlet of the air chamber 7, the air inlet of the burner 8 in the combustion chamber, and the air inlet of the air distribution ring 10;

[0054] 2) The bed material and waste wood are fed into the crushing pyrolysis chamber 4 through the bed material feeding pipe and the waste wood feeding pipe respectively, the waste wood material is fed continuously, and the filtered air passes through the air chamber 7 and the second air cap 6 The high-temperature flue gas containing combustible gas is spray...

Embodiment 3

[0059]1) Finished activated carbon is placed in the filter 2 as an adsorbent, and the suction fan 1 extracts air containing high-concentration organic waste gas from the hot air circulation system of the wallpaper processing and coating machine, and the air containing high-concentration organic waste gas is filtered and adsorbed by filter 2, Most of the organic waste gas is adsorbed in the finished activated carbon, and the filtered air containing trace organic matter is sent to the air inlet of the air chamber 7, the air inlet of the burner 8 in the combustion chamber, and the air inlet of the air distribution ring 10;

[0060] 2) The bed material and waste wood are fed into the crushing pyrolysis chamber 4 through the bed material feeding pipe and the waste wood feeding pipe respectively, the waste wood material is fed continuously, and the filtered air passes through the air chamber 7 and the second air cap 6 The high-temperature flue gas containing combustible gas is spraye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com