Method and device for co-processing regenerated gelled composite particles and carbon dioxide-containing industrial waste gas

A technology for composite materials and industrial waste gas, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve problems such as accumulation, hazards, and health hazards, and achieve low porosity and water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

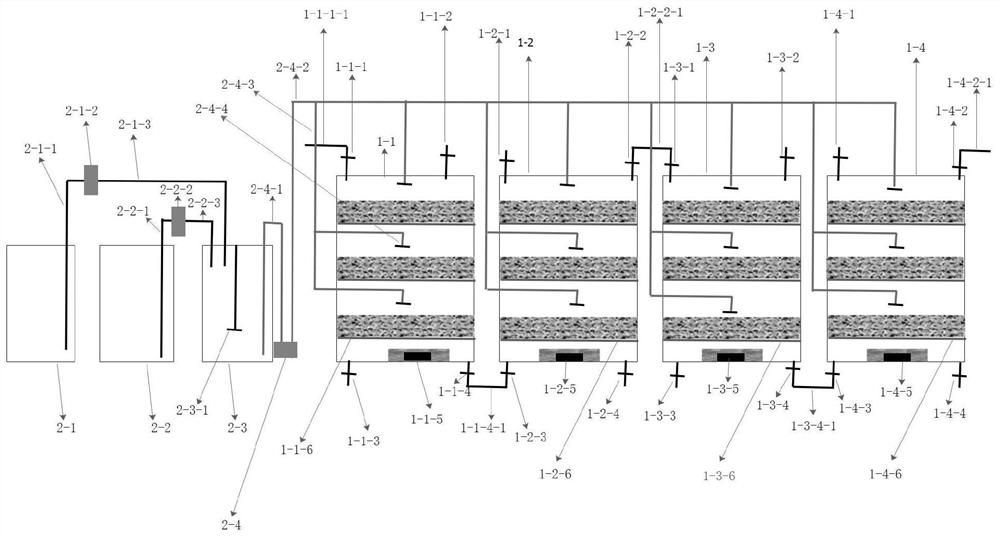

Image

Examples

Embodiment 1

[0081]Mix beef extract, peptone and distilled water evenly, sterilize at 121° C. for 15 minutes, and then cool to room temperature (25° C.) to obtain a beef extract medium. The content of beef extract in the beef extract medium is 3 g / L, and the content of peptone is 12 g / L; Mix 3-cyclohexylamino-1-propanesulfonic acid and distilled water evenly, adjust the pH value to 10 with 6mol / L sodium hydroxide solution, sterilize at 121°C for 15min, and then cool to room temperature to obtain 3-cyclohexane Hexylamino-1-propanesulfonic acid medium, the content of 3-cyclohexylamino-1-propanesulfonic acid medium in the 3-cyclohexylamino-1-propanesulfonic acid medium is 140g / L; Mix beef extract medium and 3-cyclohexylamino-1-propanesulfonic acid medium at a volume ratio of 80:20 to obtain a microbial medium; inoculate Bacillus B6 into the microbial medium and shake at 25°C Cultivate for 12 hours with an oscillation frequency of 180rpm, centrifuge after the end of the cultivation, wash the ...

Embodiment 2

[0091] Mix beef extract, peptone and distilled water evenly, sterilize at 121°C for 15 minutes, and then cool to room temperature (25°C) to obtain a beef extract medium. The content of beef extract in the beef extract medium is 5g / L, and the content of peptone is 15g / L; Mix 3-cyclohexylamino-1-propanesulfonic acid and distilled water evenly, adjust the pH value to 10 with 6mol / L sodium hydroxide solution, sterilize at 121°C for 15min, and then cool to room temperature to obtain 3-cyclohexane Hexylamino-1-propanesulfonic acid medium, the content of 3-cyclohexylamino-1-propanesulfonic acid medium in the 3-cyclohexylamino-1-propanesulfonic acid medium is 150g / L; Mix beef extract medium and 3-cyclohexylamino-1-propanesulfonic acid medium at a volume ratio of 80:20 to obtain a microbial medium; inoculate Bacillus H4 into the microbial medium and shake at 30°C Cultivate for 10 hours with an oscillation frequency of 180rpm, centrifuge after the end of the cultivation, wash the obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com