Medium-temperature solar heat collector

A technology of solar heat collectors and high temperature resistance, which is applied in the directions of solar heat collectors, solar heat collector heat insulation, solar heat collector parts, etc., and can solve the problem of reducing the range of solar heat utilization, low efficiency for commercial use, High operating costs and other issues, to achieve the effect of improving heat collection efficiency, fast heat start, and high heat collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

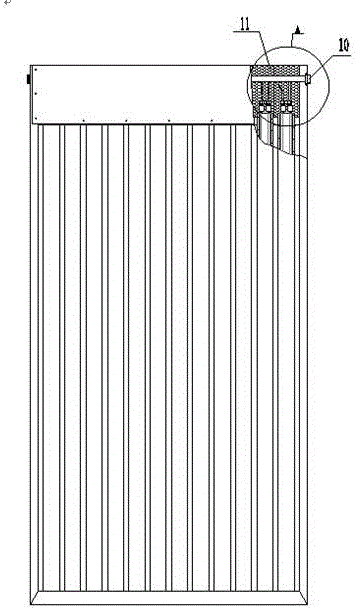

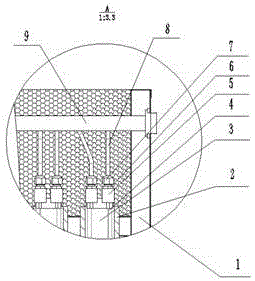

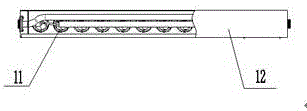

[0011] First, weld the connecting joint (5) to the upper end of the curved metal runner (3), apply the high temperature resistant heat-conducting adhesive (4) on the upper part of the curved metal runner (3), and insert the curved metal runner (3) into the vacuum tube (2) Inside, the communication joint (5) is located outside the vacuum tube at the upper end of the curved metal flow channel (3). Put the gasket (6) into the upper part of the communication joint (5), put the vacuum tube (2) into the frame (1), and place the manifold (8) Insert the sodium joint (7) Screw the sodium joint (7) into the upper part of the communication joint (5), insert the manifold (8) into the lower part of the main flow channel (9) and weld it, and connect the joint (11 ) into the two ends of the main flow channel (9) and welded, fix the lower end cover (14) on the upper bottom of the frame (1), fill the insulation material (12) in the vacuum tube (2) and on the lower end cover (14) ,) Fix the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com