Geothermal heat exchanger capable of improving heat transfer efficiency for prefab energy balls

A technology of heat transfer efficiency and energy balls, which is applied in the field of buried pipes in ground source heat pump systems and soil heat pumps for building heating and cooling. Insufficient and other problems to achieve the effect of avoiding collapse, small excavation volume, and improving heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

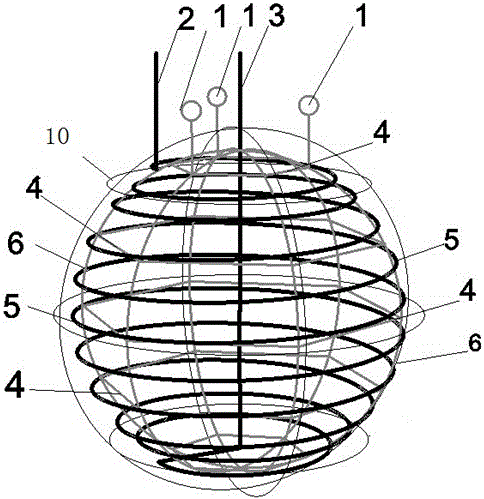

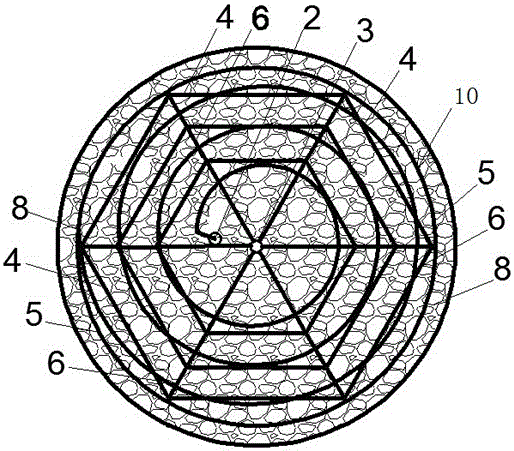

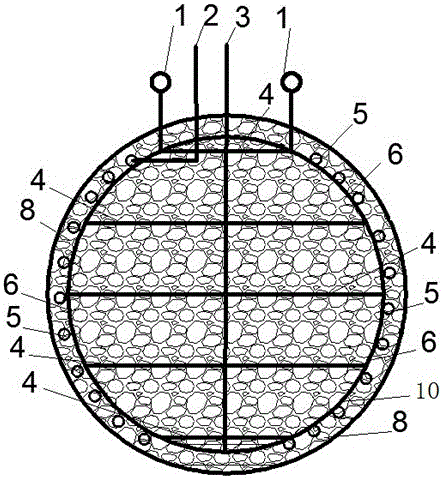

[0029] figure 1 — image 3 The shown structural diagram of the prefabricated energy sphere heat exchanger of the present invention that improves heat transfer efficiency includes a spheroid skeleton 10, and the spheroid skeleton 10 is composed of prefabricated energy sphere structural ribs 6 and prefabricated energy sphere stirrups 4, with a diameter of 1000~ 2000mm; the prefabricated energy ball structural ribs 6 are circular, the number is two groups or more, vertically arranged along the circumference of 360 degrees to form the meridian of the sphere, the diameter of the prefabricated energy ball structural ribs 6 is 60 smaller than the diameter of the energy sphere ~100mm, the steel bar diameter is 15~25mm, there are three sets of structural bars 6 in the figure, the upper and lower parts of the prefabricated energy ball structural bars 6 cross at the same point, and are connected by welding or binding, and the prefabricated energy ball stirrups 4 It is a regular polygon,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com