An electro-hydraulic load simulator error symbol integral robustness control method

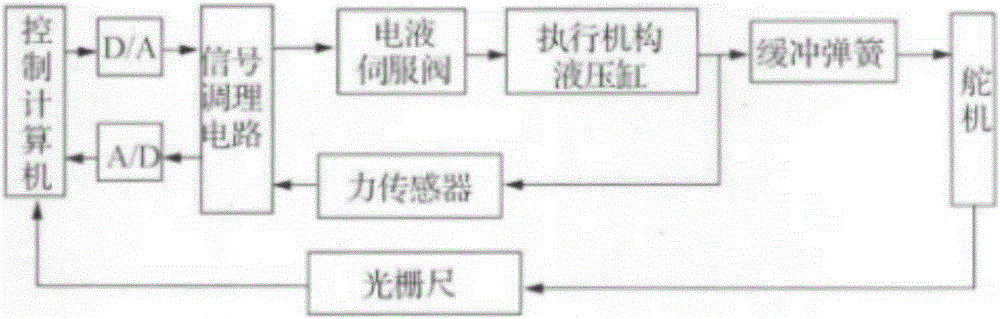

An electro-hydraulic load and error sign technology, applied in adaptive control, general control systems, control/regulation systems, etc., can solve problems such as controller discontinuity, model uncertainty, and high-gain feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

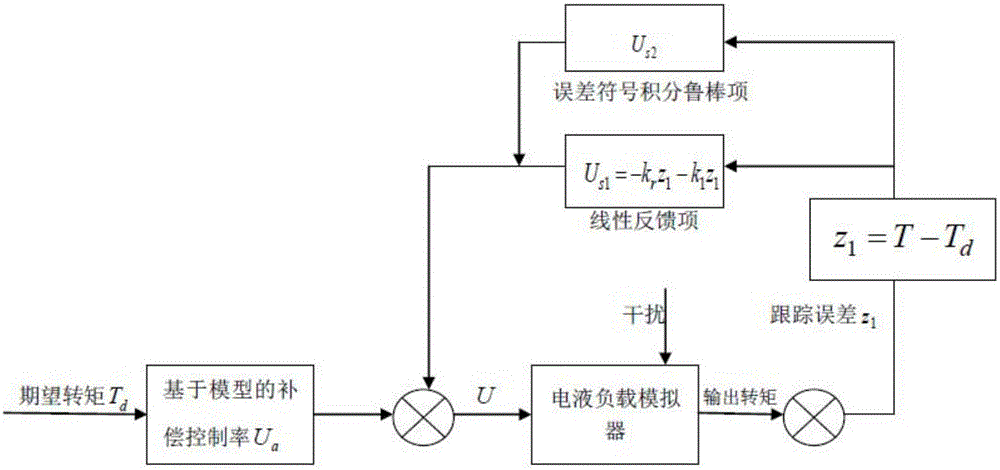

Method used

Image

Examples

Embodiment

[0175] The parameters of the dual vane hydraulic motor force control load simulator are:

[0176] A=2×10 -4 m 3 / rad, B=80N m s / rad,β e =2×10 8 Pa,C t =9×10 -12 m 5 / (N·s), P s =21×10 6 Pa, P r = 0 Pa, V 01 =V 02 =1.7×10 -4 m 3 , J=0.32kg·m 2 ,a 1 =3.5×10 -4 ,a 2 =5×10 -4 ,c 1 =700,c 2 =15,c 3 =1.5

[0177] The designed controller parameters are selected as: k 1 =200,k r = 0.01, β = 0.1. The time-varying external disturbance of the system is selected as d=200sint, and the trajectory is The torque command that the system expects to track is a curve

[0178] The effect of the control law:

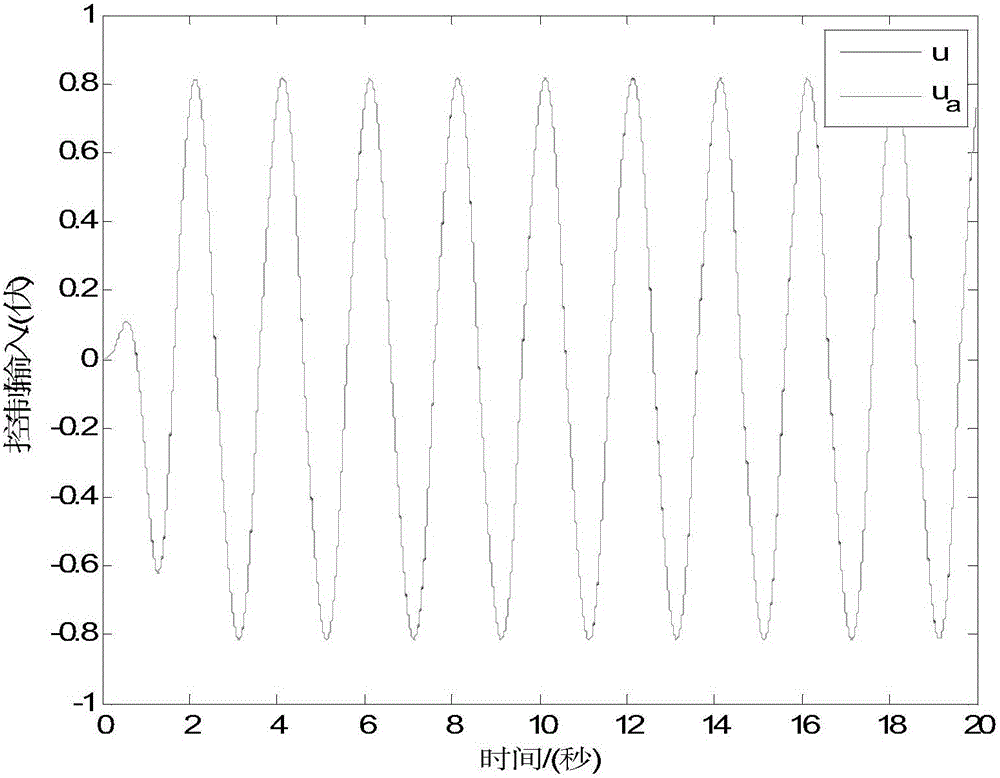

[0179] image 3 It is the u curve of the input voltage of the interference controller, the control input signal is continuous, and the input voltage meets the input range of -10V ~ +10V, which is in line with practical application.

[0180] combine Figure 4 and Figure 5 , it can be seen that the command signal and the tracking error curve can be seen that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com