Straw cleaning machine with waterflow stirring, mechanical feeding and positioned cleaning functions

A technology of positioning cleaning and mechanical addition, which is applied in the cleaning field, can solve the problems of large maintenance costs, achieve the effects of reducing maintenance times, preventing left and right swings, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

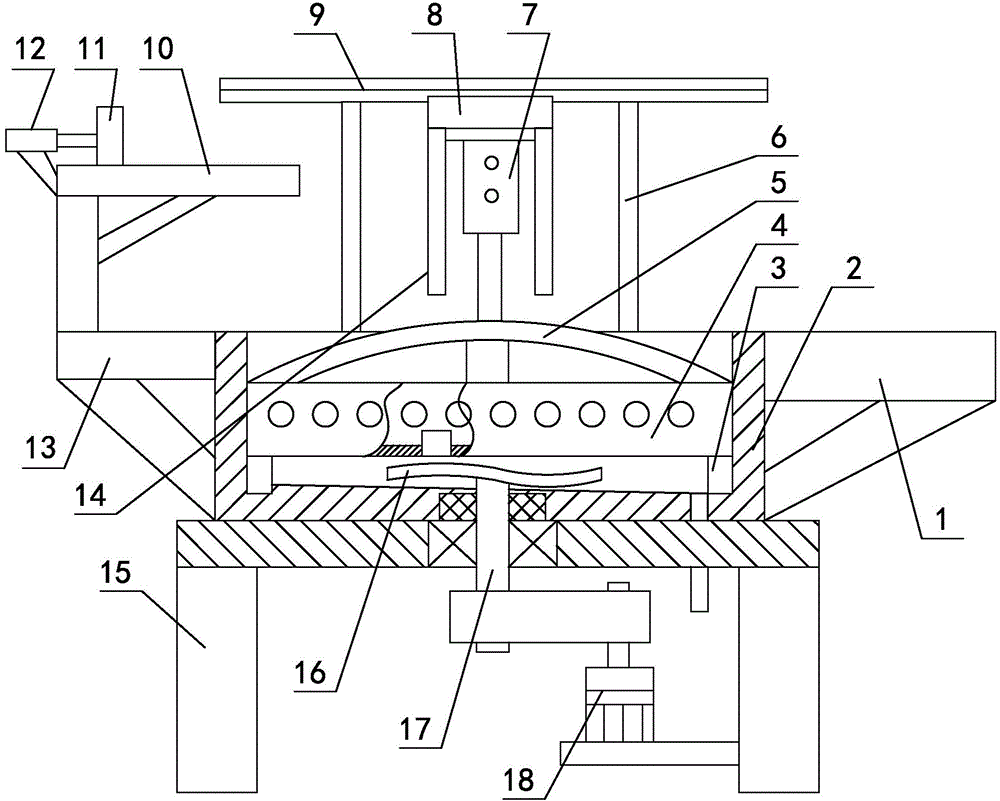

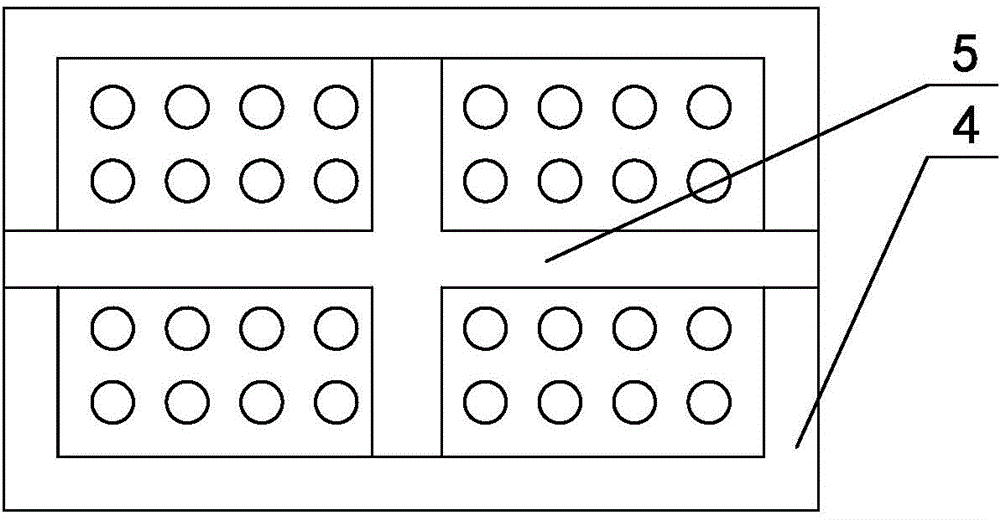

[0023] like figure 1 , figure 2 As shown, the straw cleaning machine with agitating water flow, mechanical feeding and positioning cleaning includes a cleaning tank 2, and a cleaning tank 4 for placing straws that moves up and down in the cleaning tank 2 is provided. The bottom and side walls of the cleaning tank 4 are Leakage holes are all provided, and the inner wall of the cleaning tank 2 at the bottom of the cleaning tank 4 is fixed with a stopper 3 for preventing the bottom of the cleaning tank 4 from contacting the bottom of the cleaning tank 2, and a bracket 6 is installed on the top of the cleaning tank 2. A slide rail 9 is arranged horizontally, and a slide block 8 that slides left and right is installed on the slide rail 9. A power mechanism 7 for cleaning the tank 4 to move up and down is installed at the bottom of the slide block 8. The material table 1 and the slide rail 9 extend to the upper part of the unloading table 1, and a loading table 11 for convenient l...

Embodiment 2

[0027] A change is made on the basis of Embodiment 1, the power mechanism 7 is a cylinder, the cylinder body of the cylinder is installed on the bracket 6, and the piston rod of the cylinder is connected with the handle 5; the inclination angle of the inclined surface is changed to 20 degrees. Others are the same as embodiment one.

Embodiment 3

[0029] Changes are made on the basis of Embodiment 1. The power mechanism 7 includes a screw and a nut that cooperate with each other. The lower end of the screw is vertically fixed on the handle 5, and the upper end passes through the bracket 6 independently. The nut is arranged above the bracket 6. The gear set is connected with the power transmission of the motor; the inclination angle of the inclined surface becomes 16 degrees. Others are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com