Two-grade screw rod compressor with flexible slide valve

A screw compressor and compressor technology, applied in the field of compressors, can solve the problems of compressor vibration and noise increase, pressure mismatch, increased power consumption, etc., and achieve the effects of reducing noise and vibration, reducing power and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

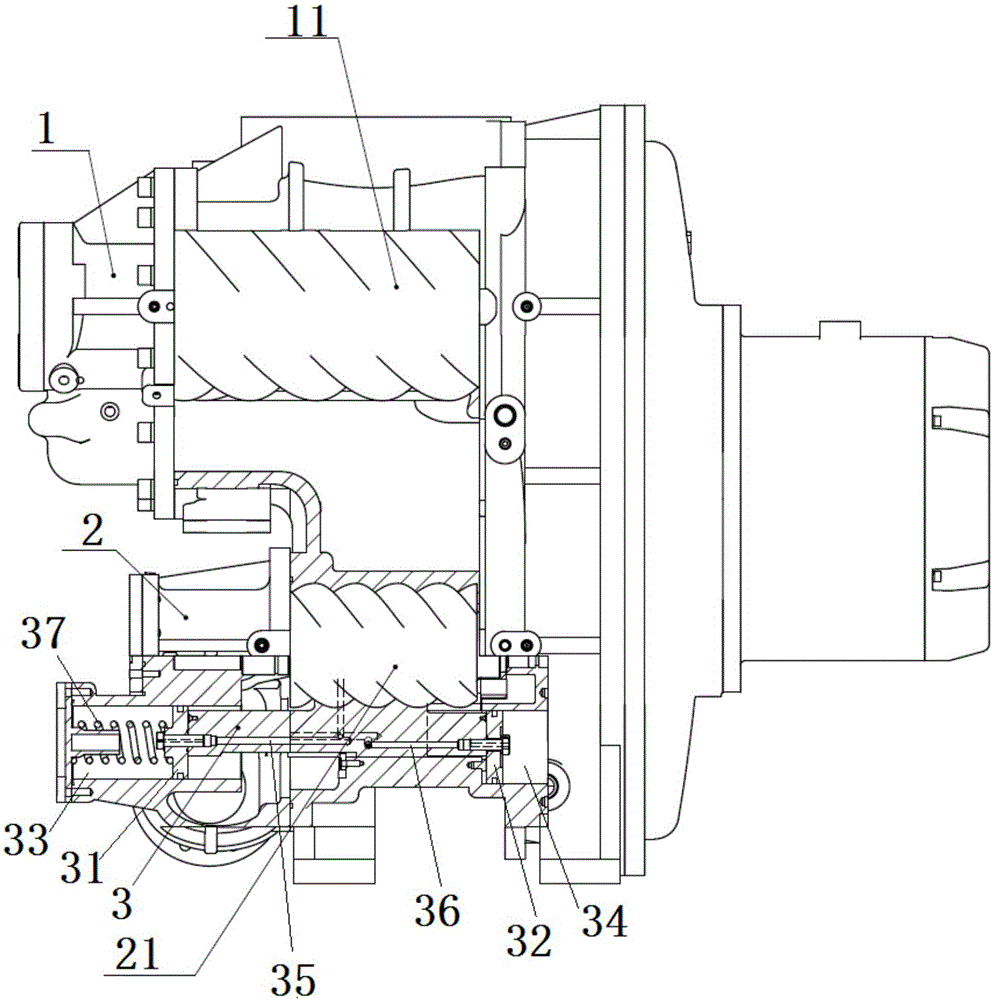

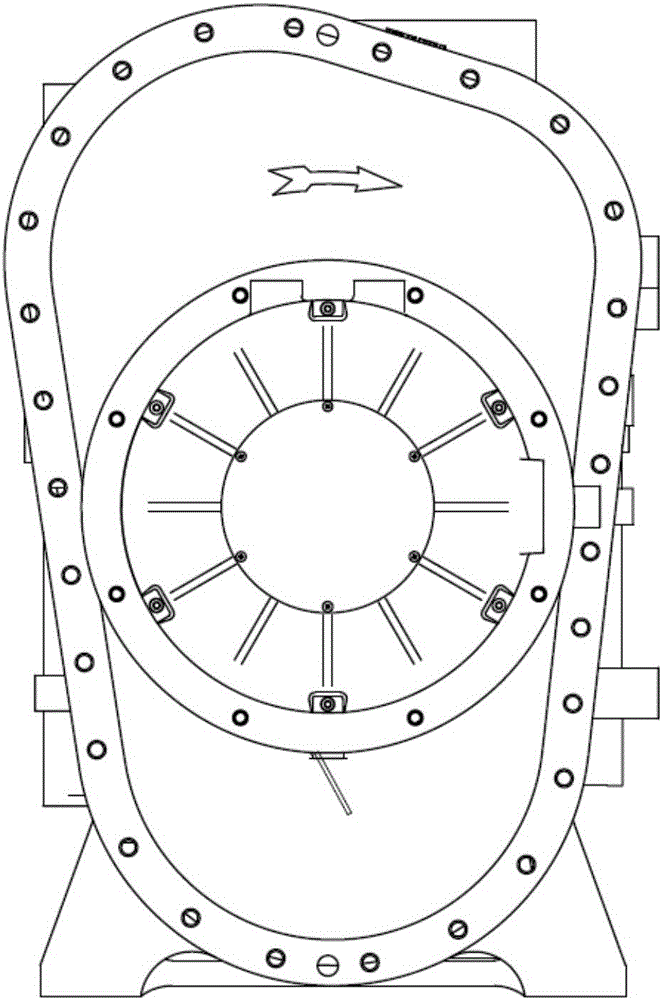

[0042] see figure 1 , figure 2 , the present invention discloses a two-stage screw compressor with a flexible slide valve (also applicable to multi-stage screw compressors), the screw compressor includes: a body, a first-stage compression mechanism 1, a second-stage compression mechanism 2. Transmission mechanism, slide valve 3, first cylinder 33, second cylinder 34.

[0043] The body of the two-stage screw compressor adopts an integrated design, including the air inlet of the two-stage screw compressor, the working chamber of the first-stage compressor, the working chamber of the second-stage compressor, the first-stage compression exhaust port and the second-stage compressor. The two-stage compressed air inlets are communicated through built-in interstage passages.

[0044] The first-stage compression mechanism 1 includes a first-stage rotor 11, and the first-stage rotor 11 is arranged in the working chamber of the first-stage compressor; the second-stage compression mech...

Embodiment 2

[0055] A two-stage screw compressor with a flexible slide valve, the screw compressor includes: a machine body, a first-stage compression mechanism, a second-stage compression mechanism, a transmission mechanism, a slide valve, a first cylinder, and a second cylinder.

[0056] The body of the two-stage screw compressor adopts an integrated design, including the air inlet of the two-stage screw compressor, the working chamber of the first-stage compressor, the working chamber of the second-stage compressor, the first-stage compression exhaust port and the second-stage compressor. The two-stage compressed air inlets are communicated through built-in interstage passages.

[0057] The first-stage compression mechanism includes a first-stage rotor, and the first-stage rotor is arranged in the working cavity of the first-stage compressor; the second-stage compression mechanism includes a second-stage rotor, and the second-stage rotor and the slide valve are arranged in the In the wo...

Embodiment 3

[0062] The difference between this embodiment and Embodiment 1 is that in this embodiment, the screw compressor includes: a compressor housing, an intake valve, and a rotor, and the intake valve includes an intake valve body, a piston, a solenoid valve, a connecting pipeline; the screw compressor is a two-stage screw compressor.

[0063] The compressor housing adopts an integrated design, including the air inlet of the two-stage screw compressor, the first-stage compressor working chamber, the second-stage compressor working chamber, the first-stage compression exhaust port and the second-stage compressor The intake ports are communicated through built-in interstage passages. A pressure-taking port is provided at the interstage channel, and the pressure-taking port is connected with the rear end of the piston of the intake valve.

[0064] After the screw compressor is started, the working pressure is rapidly established in the area where the pressure-taking port provided at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com