Bearing box of slime pump

A bearing box and mud pump technology, which is applied in the field of mud pumps, can solve problems such as bearing damage and mud pump failure to operate normally, and achieve the effect of improving sealing performance and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

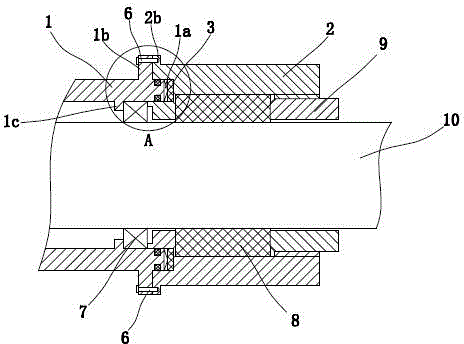

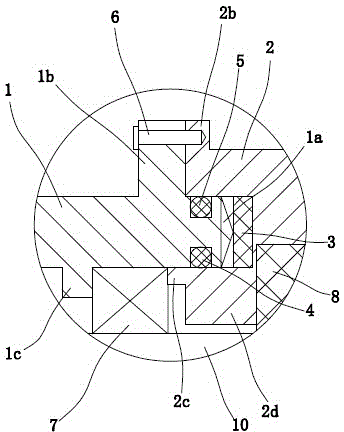

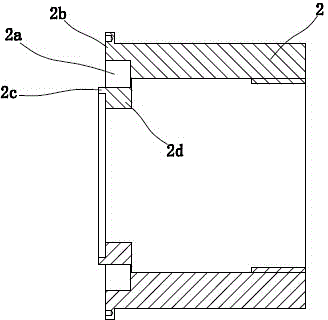

[0036] Such as figure 1 As shown, the mud pump bearing box includes a left casing 1 and a right casing 2 which are both cylindrical, and the centerline of the left casing 1 and the centerline of the right casing 2 are collinear.

[0037] One end surface of the right housing 2 has an annular groove 2a, the inner end of the left housing 1 is inserted into the annular groove 2a, and a sealing structure is provided between the left housing 1 and the right housing 2 to make the connection and sealing of the two Two, thereby preventing mud from entering the bearing 7 box from the gap between the left housing 1 and the right housing 2 .

[0038] Specifically, as figure 1 and figure 2 As shown, the second sealing structure is the gasket 3 in the annular groove 2a, the gasket 3 is annular, and the two sides of the gasket 3 respectively abut against the inner end of the left housing 1 and the bottom wall of the annular groove 2a. For further optimization, there is a protrud...

Embodiment 2

[0044] The structure and principle of the second embodiment are basically the same as those of the first embodiment, except that the second sealing structure is a gasket located between the annular shoulder 1b and the annular shoulder 2b. By providing a gasket between the annular shoulder 1b and the annular retaining shoulder 2b, the connection between the left housing 1 and the right housing 2 can also maintain good sealing performance, which has the advantages of simple structure and good sealing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com