Subgrade settlement monitoring system based on MEMS sensor

A settlement monitoring and sensor technology, which is applied in signal transmission systems, instruments, measuring devices, etc., can solve the problems of large mutual influence, easy damage of settlement plates, and difficult to meet the requirements of precision, and achieve small construction impact, convenient later maintenance, and small size The effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

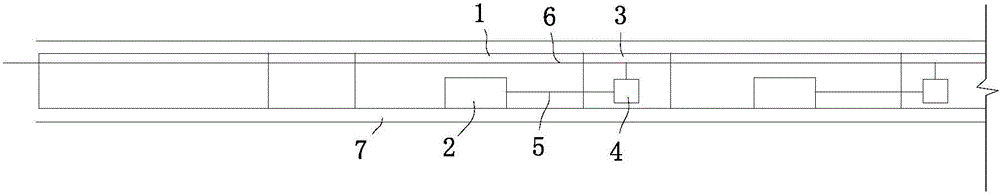

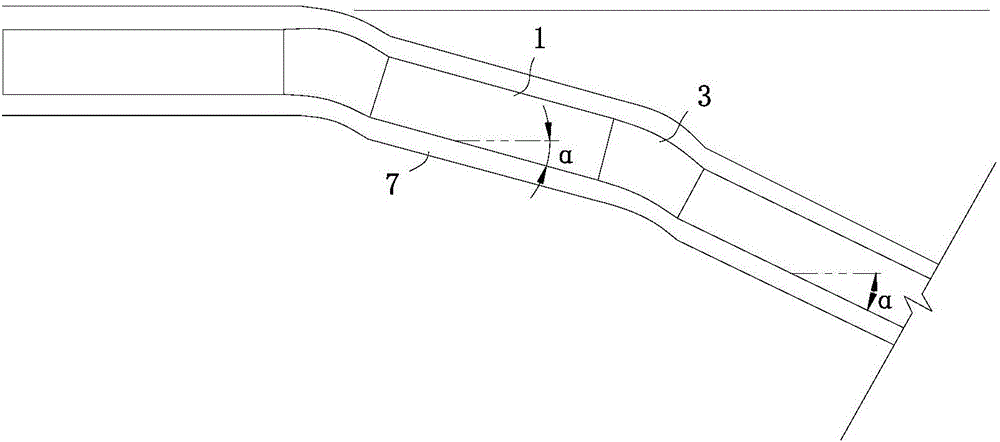

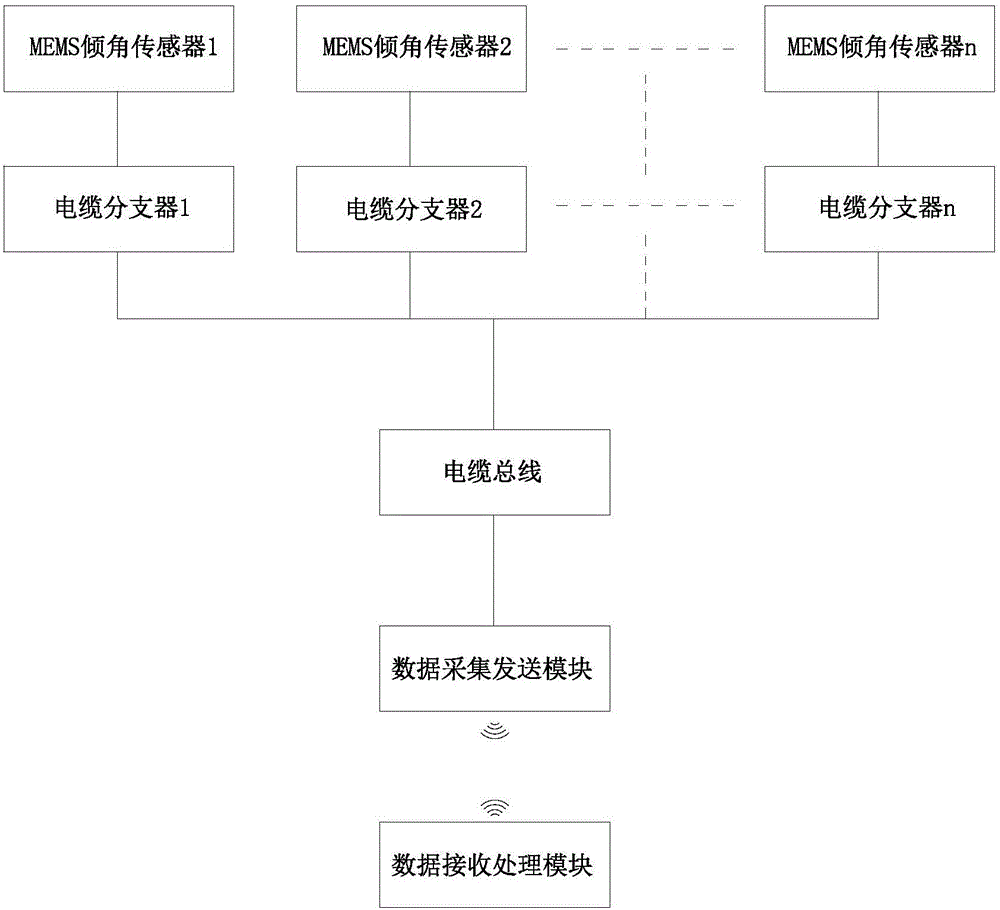

[0015] refer to Figure 1 to Figure 3 , a subgrade settlement monitoring system based on MEMS sensors in the present invention, including a plurality of rigid pipes 1 connected end to end in sequence and MEMS inclination sensors 2 fixed in each rigid pipe 1, adjacent rigid pipes 1 are connected by flexible The tubes 3 are movably connected together, and each flexible tube 3 is provided with a cable splitter 4, and the MEMS inclination sensor 2 in each rigid tube 1 is correspondingly connected to the cable splitter 4 in one side of the flexible tube 3 through the cable splitter 5. Each cable splitter 4 is connected through a cable bus 6 passing through each rigid pipe 1 and each flexible pipe 3 .

[0016] In this embodiment, steel pipes are used for each section of rigid pipe 1, and metal hoses are used for each section of flexible pipe 3. Since each section of rigid pipe 1 is connected by flexible pipe 3, each section of rigid pipe 1 can only rotate relative to each other. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com