Creep test device and control system thereof

A technology of creep test and controller, which is applied in the field of compression creep test of similar materials, can solve the problem that the loading accuracy of small tonnage axial load cannot be guaranteed, the stability and continuity of axial load cannot be guaranteed, and the deformation measurement cannot be satisfied. Precision requirements and other issues, to achieve the effect of improving space utilization, stable work, and reasonable space design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

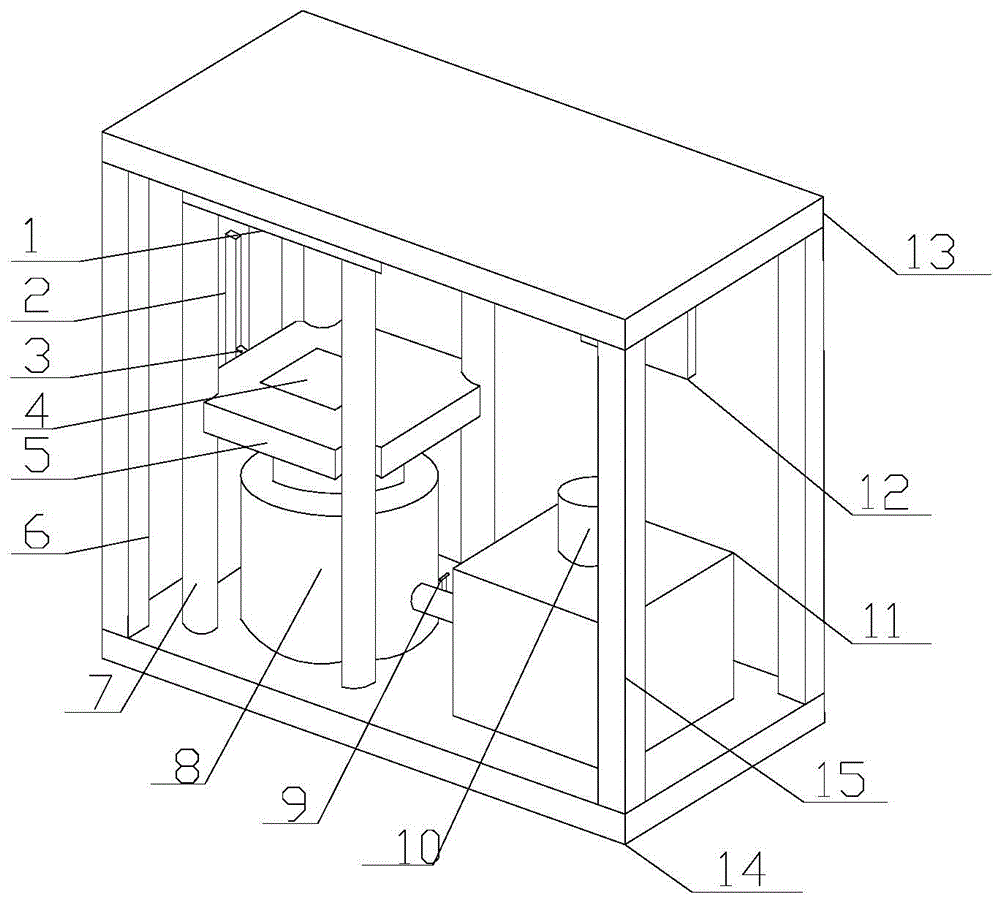

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

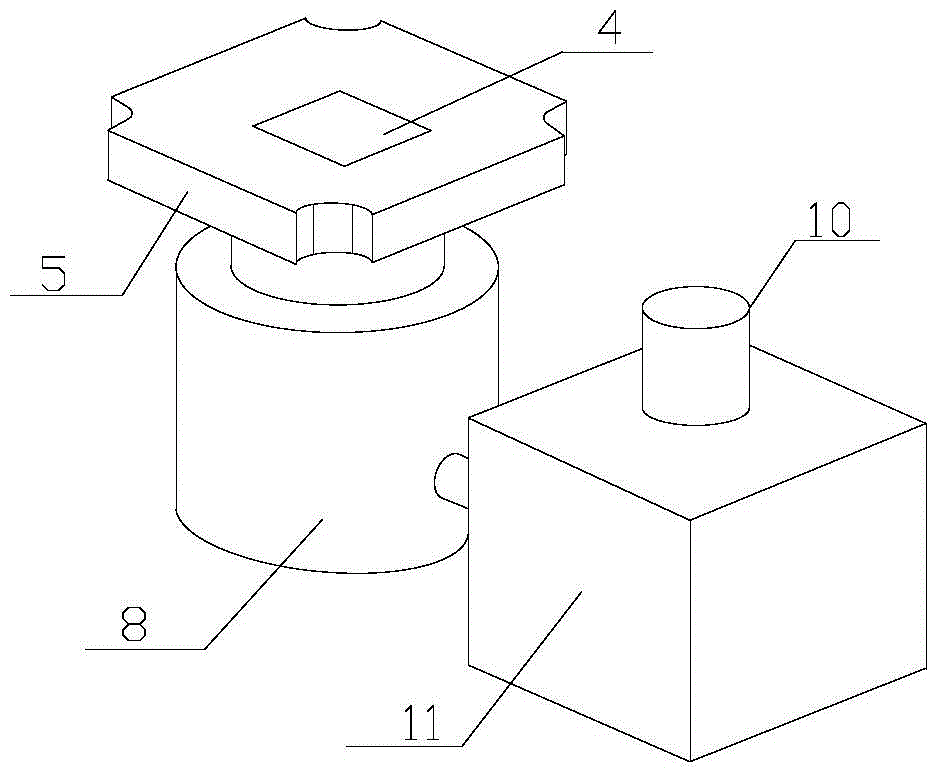

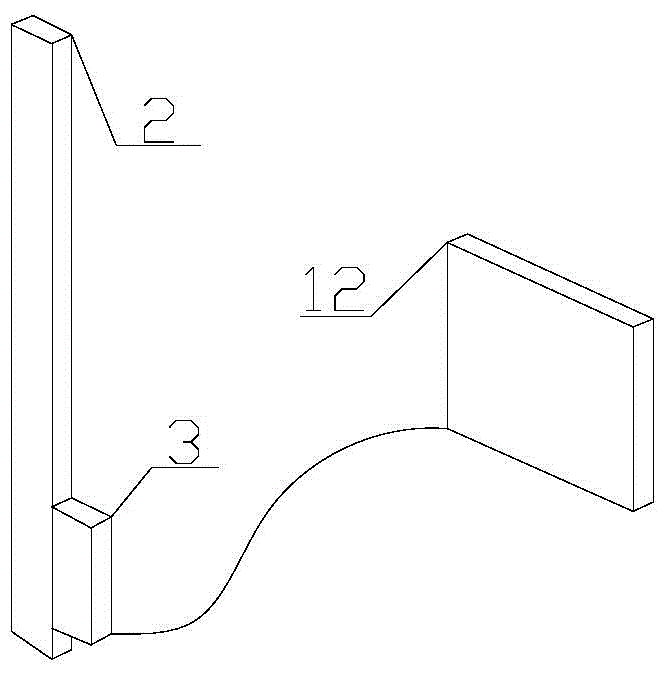

[0045] In the figure, a creep test device. Including the control system, which is composed of scale grating 2 and grating reading head 3. The scale grating 2 is fixed vertically on the left side of the test bench, and the grating reading head 3 is fixed on the lower pressure plate 5. During the installation process, ensure that the ruler body is parallel to the guide rail , its parallelism meets the installation requirements (the parallelism cannot exceed 0.1mm, and the maximum parallelism cannot exceed 0.15mm). During the creep process of the specimen, the grating reading head 3 moves with the lower pressure plate 5 to record the displacement change. The grating reading The head 3 is connected with the controller 12 through cables, and records relevant data in real time.

[0046] The loading system is composed of a hydraulic oil tank 11, an electric pump 10, and a hy...

Embodiment 2

[0050] When a hydraulic jack is used, the hydraulic jack can also be set above the test piece and fixedly connected with the top cover of the reaction force frame, so that the hydraulic jack can apply load from top to bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com