Method for detecting flaw through infrared thermography

An infrared thermal imaging and defect technology, applied in the direction of material defect testing, etc., can solve the problem of extraction without considering the size of the defect, without giving the three-dimensional image or cross-sectional view of the tomographic reconstruction, and achieve high-quality results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

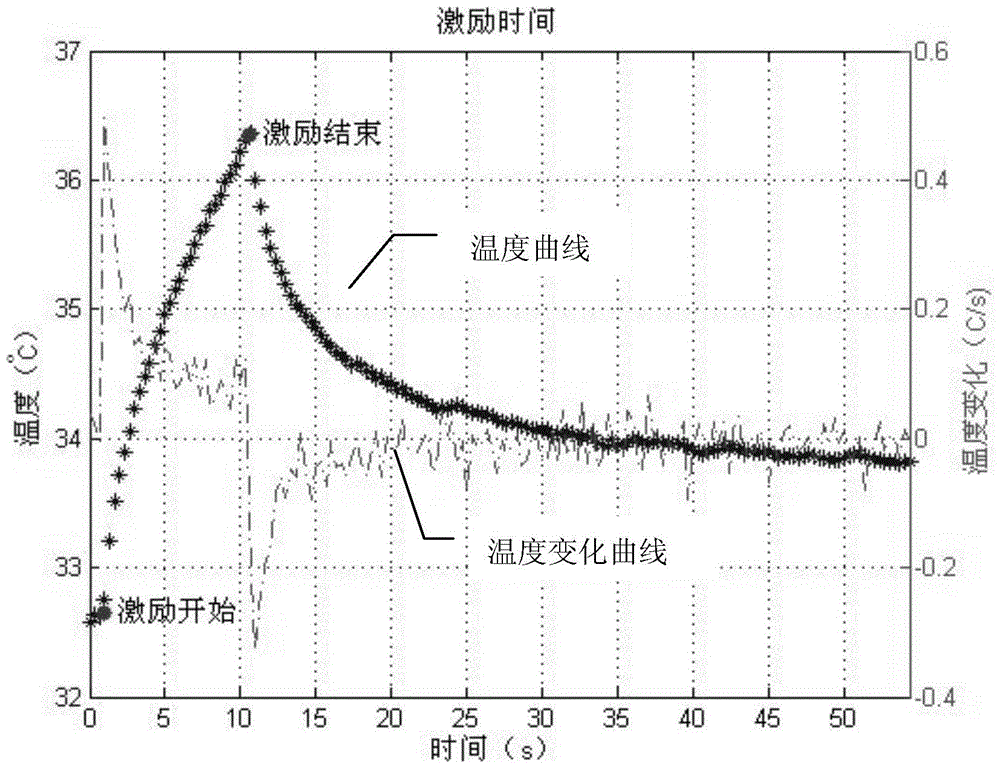

[0029] Step 1: Perform thermal excitation on the test piece, and simultaneously use an infrared thermal imager to obtain time-series detection thermal images of the surface of the test piece before, during and after the excitation for a period of time.

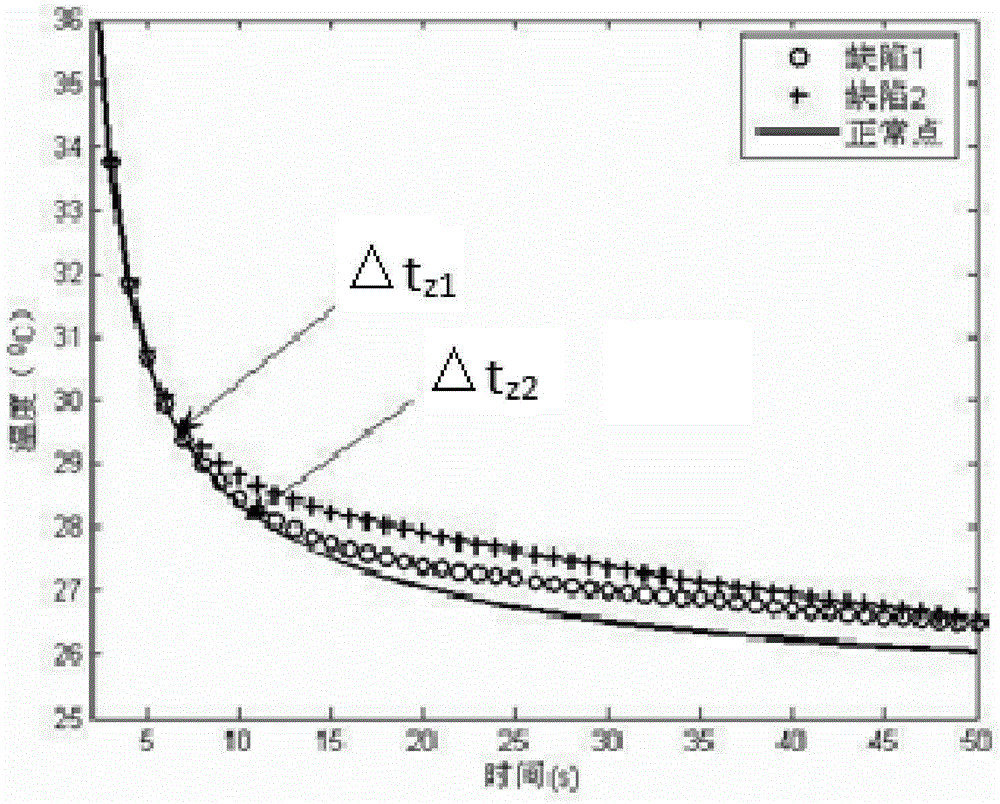

[0030] Specifically, in the infrared thermal image detection, a lamp or hot air is used to thermally excite the tested piece, while the infrared thermal imager records the time-series detection thermal images of the surface of the tested piece on the same side of the tested piece. see figure 1 , figure 1 pairs with different depth Z 1 ,Z 2 The test piece of the flat-bottomed blind hole defect is tested, and the time-series detection thermal image of the normal area and the defect area is obtained. The curve of the temperature change with time. According to the heat conduction model, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com