Assembly falloff defect identification method and system of overhead contact system

A technology for component shedding and defect identification, applied in the catenary field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0055] (1) Identification method of component shedding defects in catenary

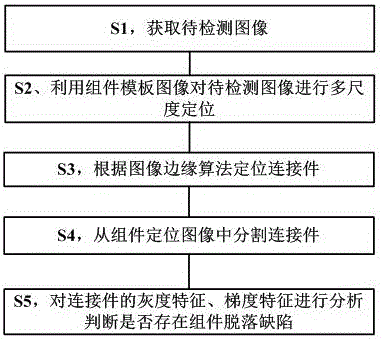

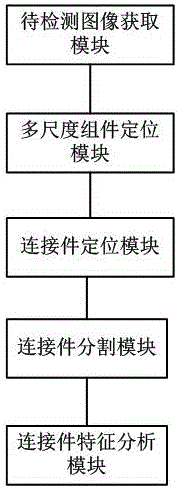

[0056] Such as figure 1 As shown, this embodiment describes a method for identifying component shedding defects in the catenary. Each component in the catenary is connected by a connector. The method is used to detect whether there is a shedding defect in the connector. The connector can be Includes screws, nuts, bolts, etc. The present invention is suitable for detecting various connectors of each component, and only needs to adopt different parameters for different components and different connectors, and the principle is basically the same.

[0057] The method proposed by the present invention comprises the following steps:

[0058] S1, acquiring an image to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com