High intensity sweetener composition

A technology of high-intensity sweetener and composition, applied in the field of sweetener composition of sucralose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0094] In Examples 1-4 below, agglomerated sweetener compositions were prepared by agglomerating maltodextrin (DE=6) and micronized sucralose in a Lodige LFPmini2 agglomerator, wherein the nozzle insert In top spray configuration.

[0095] Example 1 - 30% Sucralose, Whole Sucralose Content Dissolved in Solution

[0096] 143 grams of maltodextrin were placed in a fluidized bed and agglomerated with 600 grams of a solution consisting of 143 grams of maltodextrin, 114 grams of micronized sucralose and 400 grams of water. The procedure operates with the following parameters:

[0097] product temperature

[0098] After all the solution has been sprayed, the pump and heater are turned off and the product is allowed to dry for 1 minute. The finished product is discharged from the chamber and screened through a 1mm screen to remove large particles.

[0099] Example 2 - 30% sucralose, half of the total sucralose content dissolved in liquid, and half of the sucralose ...

example 5

[0111] Example 5 - Properties of agglomerates

[0112] The water content of the agglomerates was determined by Karl Fischer analysis using a Karl Fischer titrator (complex 2 reagent).

[0113] The particle size was measured with a Beckman LS320 laser diffraction analyzer.

[0114] Density was measured with an Erwekadensi-volumeter using 250 ml graduated tubes.

[0115] The samples in the table below (prepared according to Examples 1 to 4 above) were analyzed:

[0116]

[0117]

example 6

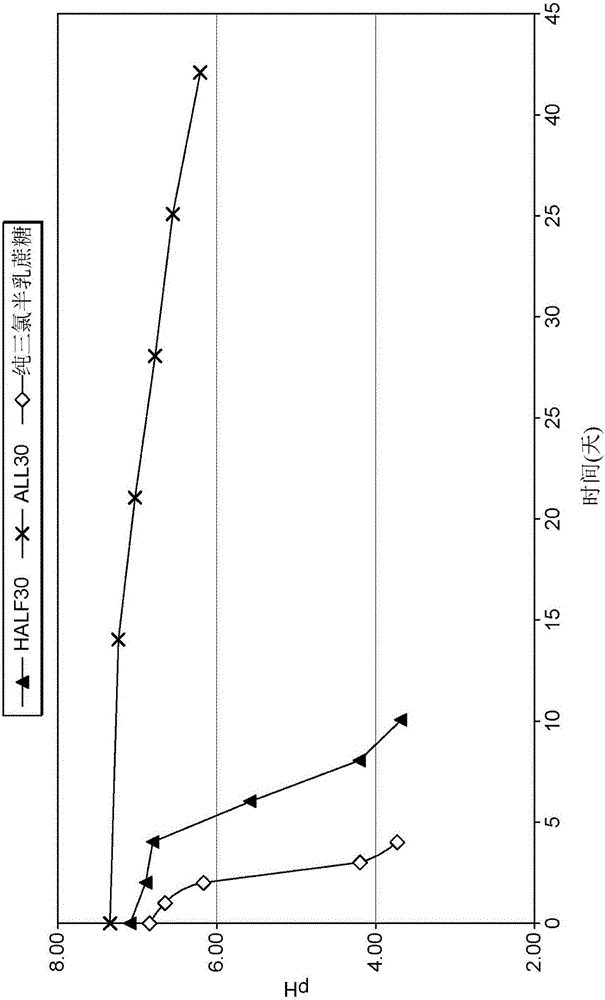

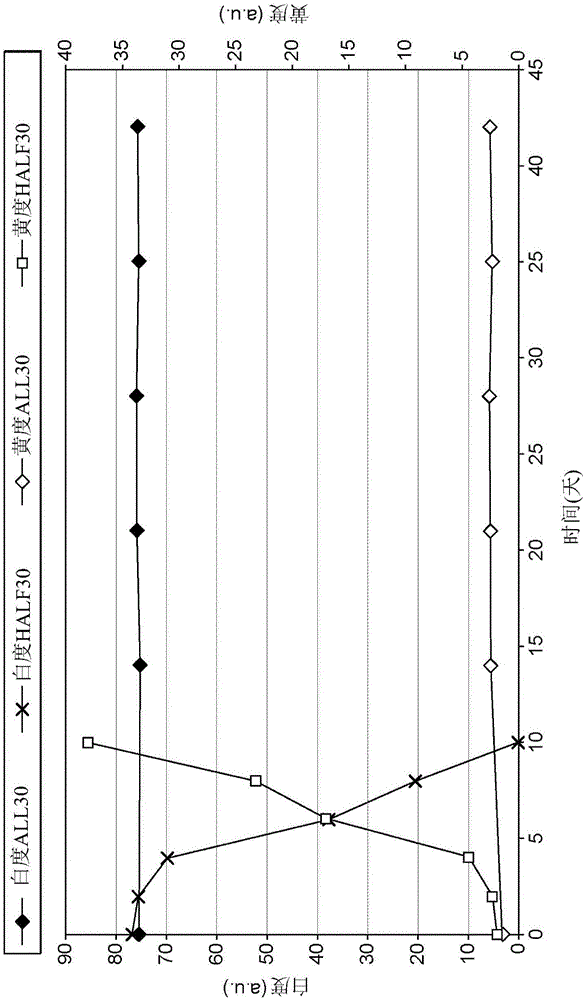

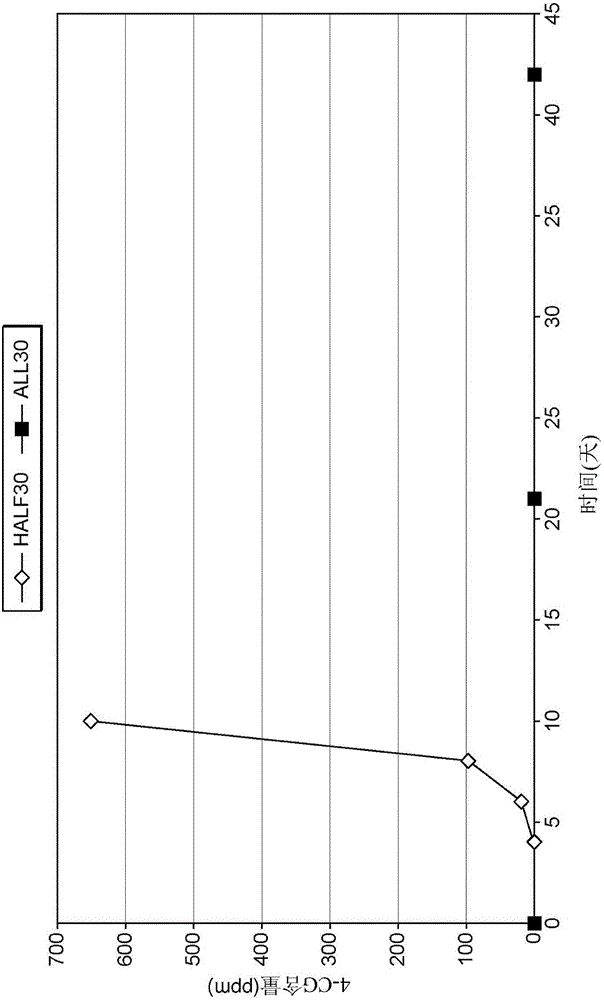

[0118] Example 6: Thermal stability of agglomerates

[0119] The resulting agglomerates were exposed to accelerated aging in an oven set at 50°C in airtight packaging to prevent loss of moisture. Samples were periodically removed from the oven and analyzed for pH, color (whiteness and yellowness), sucralose content and 4-chlorogalactose content.

[0120] Sucralose content was determined by HPLC. The samples were previously diluted to 10% concentration (weight / weight) with water adjusted to pH = 6 with diluted sodium hydroxide / hydrochloric acid solution, and then the pH was measured. A rapid drop in pH is an indicator of sucralose degradation. Determine Hunter color with a HunterLab colorimeter. Whiteness and yellowness values can be calculated according to ASTM E313. 4-Chlorogalactose is a by-product of thermal degradation of sucralose. Its content was determined by ion chromatography using separation on a carbohydrate anion exchange column, through a gradient of sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com