Temperature-sensitive soluble microneedle and preparation method thereof

A temperature-sensitive, soluble technology, used in pharmaceutical formulations, medical preparations with inactive ingredients, drug delivery, etc., can solve problems such as slow dissolution, increased skin irritation, and unfavorable biological drug delivery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a chitosan-β-sodium glycerophosphate-dextran temperature-sensitive soluble microneedle and a preparation method thereof, the preparation method comprising the following steps:

[0039] 1) Preparation of temperature-sensitive material solution

[0040] Take a certain amount of chitosan (degree of deacetylation greater than 95%), add 0.1mol / L hydrochloric acid solution, stir and dissolve to obtain a chitosan solution whose concentration of chitosan is 0.02g / ml; weigh a certain amount of β - Sodium glycerophosphate is dissolved in deionized water to obtain a β-sodium glycerophosphate solution whose concentration of β-sodium glycerophosphate is 1g / ml; get 1ml β-sodium glycerophosphate and add it dropwise to 5ml chitosan solution and stir for 30min to obtain the temperature Sensitive material solution.

[0041] 2) Preparation of dextran solution

[0042] A certain amount of dextran (molecular weight 40000) was weighed and dissolved in deionized wat...

Embodiment 2

[0050] This embodiment provides a chitosan-β-sodium glycerophosphate-polyvinyl alcohol-dextran temperature-sensitive soluble microneedle and a preparation method thereof, the preparation method comprising the following steps:

[0051] 1) Preparation of temperature-sensitive material solution

[0052] Take a certain amount of chitosan (degree of deacetylation greater than 95%), add 0.1mol / L hydrochloric acid solution, stir and dissolve to obtain a chitosan solution whose concentration of chitosan is 0.02g / ml; weigh a certain amount of β - Sodium glycerophosphate is dissolved in deionized water to obtain a sodium β-glycerophosphate solution with a concentration of 1 g / ml of sodium β-glycerophosphate; a certain amount of polyvinyl alcohol is weighed, dissolved in deionized water, heated and stirred to obtain polyvinyl alcohol The concentration of vinyl alcohol is the polyvinyl alcohol solution of 0.11g / ml; 1ml chitosan solution and 1ml polyvinyl alcohol solution are stirred and m...

Embodiment 3

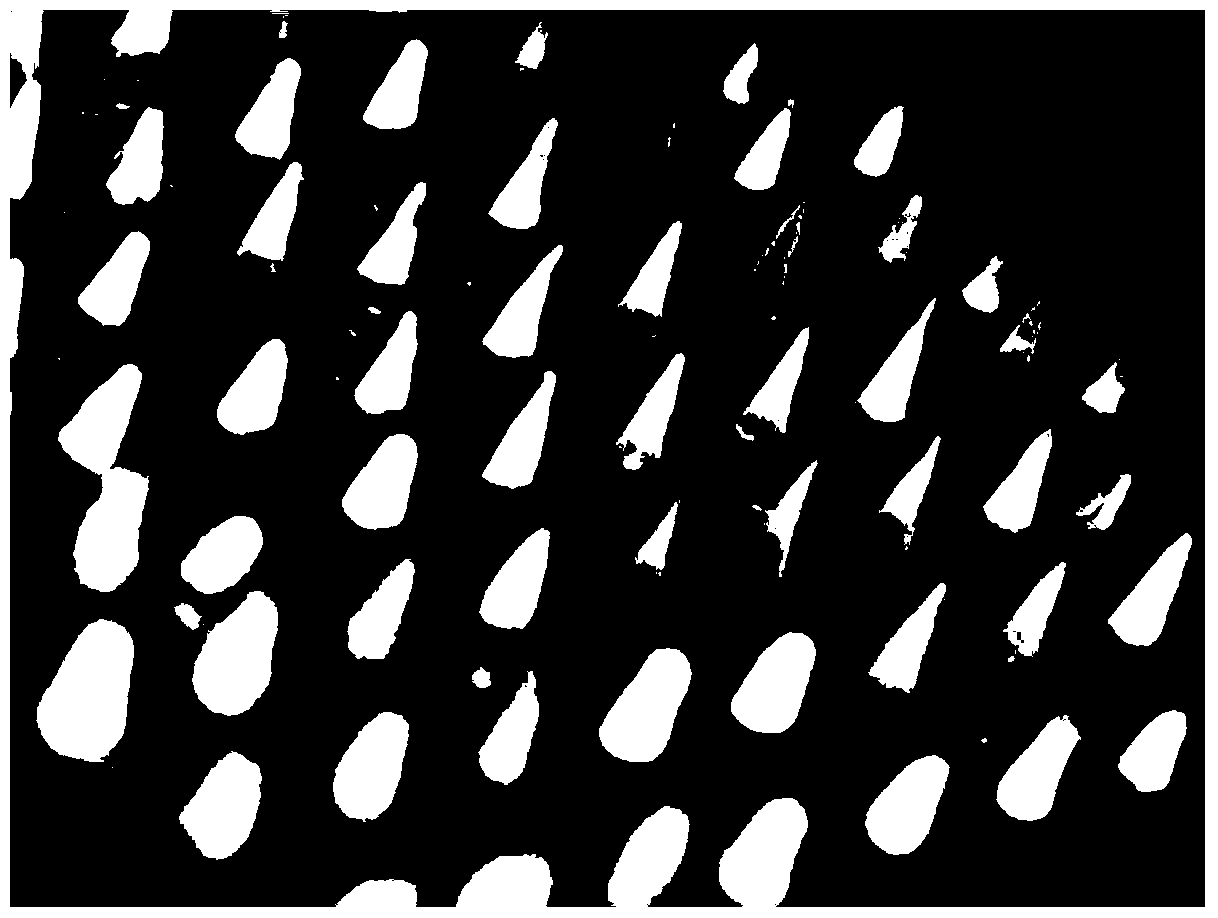

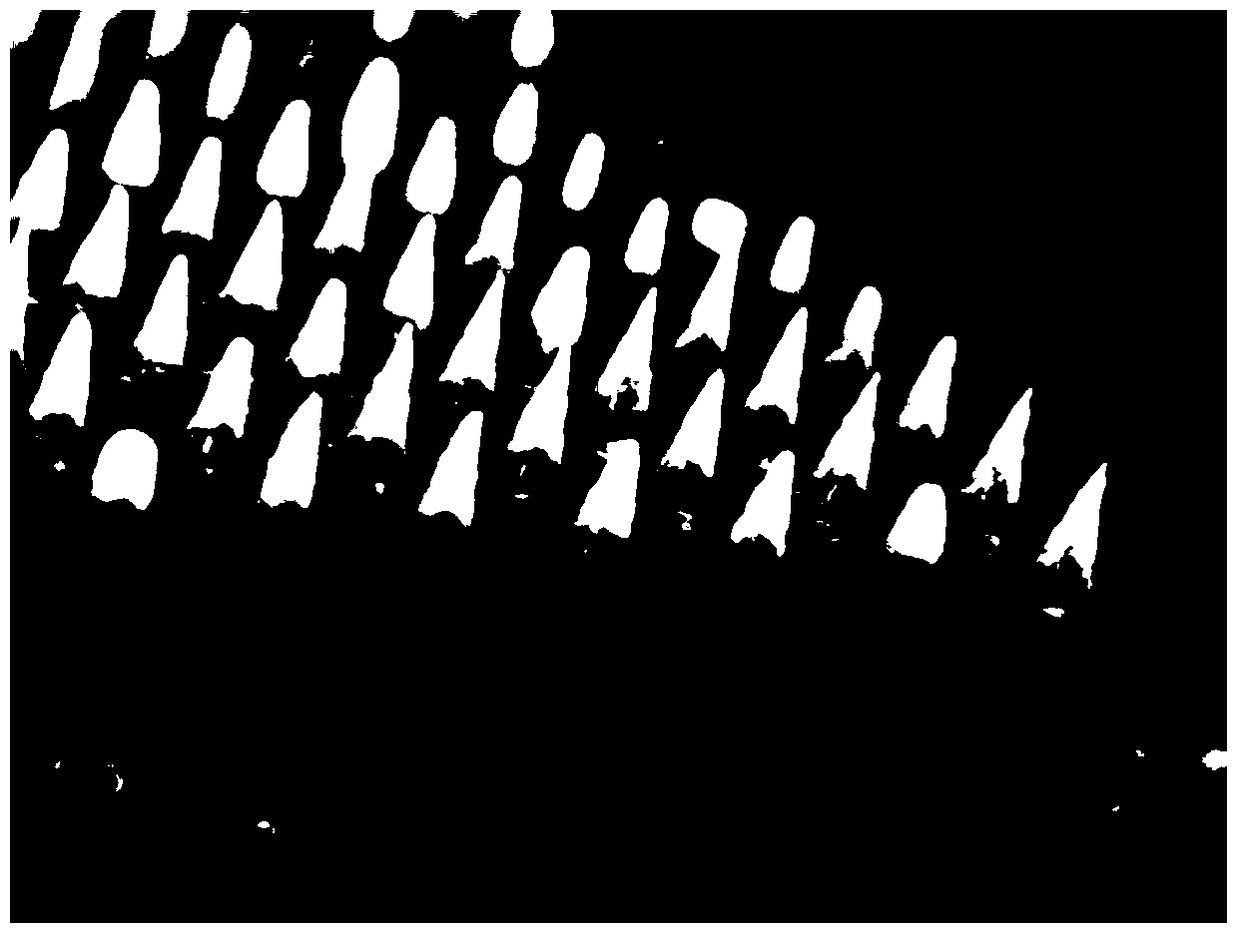

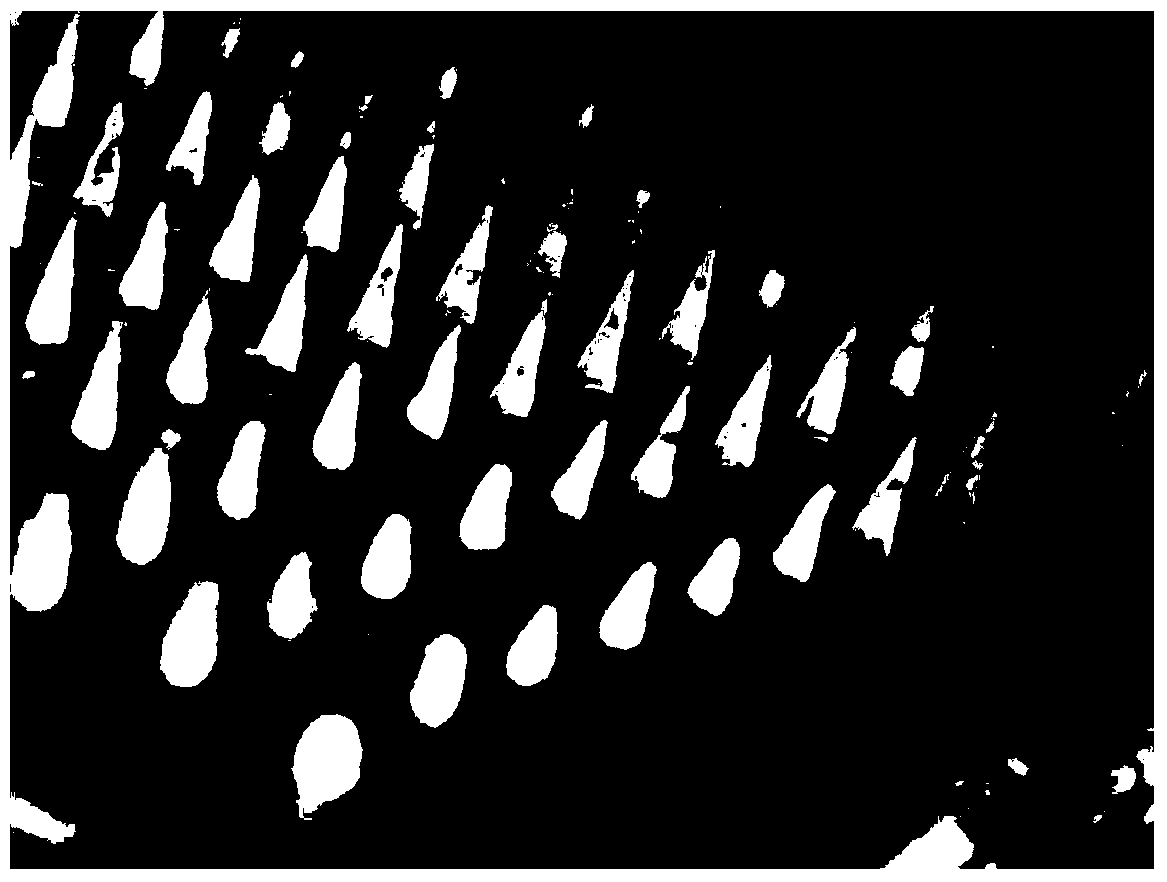

[0070] The soluble microneedles prepared in Examples 1-2 and Comparative Example 1 were tested for skin solubility. The specific method was as follows: press the soluble microneedles on the skin of the depilated rat for 2 minutes, respectively at 0 min, 2 min, and 5 min. , 10min, 20min, 30min, 60min, 120min to take out the microneedle from the skin, take pictures under the microscope to measure the remaining height of the needle tip, the results are as follows Figure 4 as well as Figure 5 shown.

[0071] The results show that: at 2 minutes, the needle tip remaining heights of Examples 1 and 2 were 69% and 62% of the original height, respectively, while the needle tip remaining height of Comparative Example 1 was 86% of the original height; The remaining needlepoint heights were 44% and 46% of the original height, respectively, while the remaining needlepoint heights of Comparative Example 1 were 58% of the original height; at 60 minutes, the remaining needlepoint heights of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com