Reaction kettle with corrosion resistant coating for modified asphalt

A corrosion-resistant coating and modified asphalt technology, which is applied in the field of reactors and reactors for modified asphalt, can solve the problems of poor quality of finished products, poor deflection effect of asphalt, uneven mixing, etc., and achieve good quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

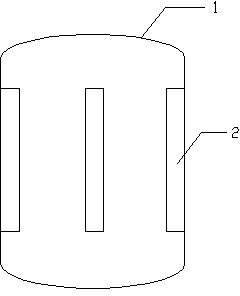

[0012] see figure 1 The present invention relates to a reaction kettle for modified asphalt with a corrosion-resistant coating, comprising a reactor body 1, the inner wall of the reactor body 1 is vertically provided with a plurality of baffles 2, and the plurality of baffles The flow plates 2 are evenly arranged in the circumferential direction. The inner wall of the reaction kettle body is provided with a corrosion-resistant coating, and the corrosion-resistant coating is made by spraying the powder for corrosion-resistant spraying. The powder for corrosion-resistant spraying includes carbide and metal element; the carbide includes TiC and WC also includes one or both of TaC and NbC; the metal element includes Co, Ni and Cr; the weight of the carbide accounts for 53% to 74% of the total weight of the corrosion-resistant spray powder, and the rest For a single metal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com